Novel solar environmentally-friendly thermal insulation material

A technology of thermal insulation materials and solar energy, applied in the field of environmental protection, can solve the problems of thermal insulation foam dimensional stability, flame retardancy and environmental protection of solar thermal insulation materials, etc., and achieve the effect of good appearance, low thermal conductivity and excellent performance of the orifice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

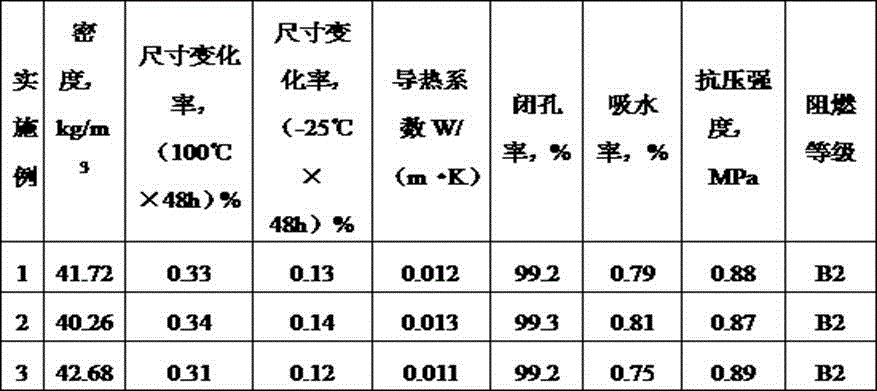

Examples

preparation example Construction

[0027] The preparation method of the novel solar energy environment-friendly thermal insulation material comprises the following steps:

[0028] S1: Mix polyurethane, polyether, and polybutenol, and stir for 6-10 minutes at a temperature of 172-182° C. and a rotation speed of 300-500 r / min to obtain a mixture a;

[0029] S2: Under the protection of nitrogen, add vinyl resin, white latex, fly ash, talcum powder, calcium carbonate powder, montmorillonite powder, silicone oil, silicon carbide fiber, glass fiber, polyester to the mixture a prepared in step 1. Acrylic fiber, hydroxypropyl methylcellulose, maleic anhydride graft compatibilizer, acrylic bridging agent, dispersant NC, stannous octoate, azodicarbonamide, acrylate foam regulator, silicone Amide, epoxy resin binder, dioctyl adipate, liquid polybutadiene rubber, polyaluminum chloride, the microwave power is 180-260W, the temperature is 136-153°C, and the rotation speed is 200-400r / min Under stirring for 3-5h, the mixture...

Embodiment 1

[0033]A new type of solar energy environment-friendly thermal insulation material, including the following raw materials in units of weight: 190 parts of polyurethane, 105 parts of polyether, 85 parts of polybutenol, 35 parts of vinyl resin, 19 parts of white latex, 10 parts of fly ash, 13 parts of talcum powder, 10 parts of calcium carbonate powder, 9 parts of montmorillonite powder, 22 parts of silicone oil, 7 parts of silicon carbide fiber, 15 parts of glass fiber, 12 parts of polypropylene fiber, 8 parts of hydroxypropyl methylcellulose, horse 1.8 parts of toric anhydride graft compatibilizer, 1.2 parts of acrylic bridging agent, 1.3 parts of dispersant NC, 0.7 parts of stannous octoate, 1.2 parts of azodicarbonamide, 0.8 parts of acrylic foam regulator, silicone 0.5 parts of amide, 1.5 parts of epoxy resin binder, 0.9 parts of dioctyl adipate, 0.5 parts of liquid polybutadiene rubber, 1.2 parts of polyaluminum chloride, 0.3 parts of p-hydroxybenzenesulfonic acid, 04 parts ...

Embodiment 2

[0041] A new type of solar energy environment-friendly thermal insulation material, including the following raw materials in units of weight: 135 parts of polyurethane, 68 parts of polyether, 52 parts of polybutenol, 25 parts of vinyl resin, 15 parts of white latex, 8 parts of fly ash, 10 parts of talcum powder, 7 parts of calcium carbonate powder, 6 parts of montmorillonite powder, 18 parts of silicone oil, 5 parts of silicon carbide fiber, 12 parts of glass fiber, 9 parts of polypropylene fiber, 6 parts of hydroxypropyl methylcellulose, horse 1.2 parts of toric anhydride graft compatibilizer, 0.7 parts of acrylic bridging agent, 0.6 parts of dispersant NC, 0.4 parts of stannous octoate, 0.8 parts of azodicarbonamide, 0.5 parts of acrylic foam regulator, silicone 0.3 parts of amide, 1 part of epoxy resin binder, 0.6 parts of dioctyl adipate, 0.4 parts of liquid polybutadiene rubber, 0.8 parts of polyaluminum chloride, 0.2 parts of p-hydroxybenzenesulfonic acid, 0.3 parts of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com