High-performance wide-spectrum solar cell material

A solar cell and wide-spectrum technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of inability to effectively use the broad-spectrum energy of sunlight, photoelectric conversion efficiency, carrier transfer efficiency, and low carrier mobility , to achieve good electron stacking performance, improve photoelectric conversion efficiency, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

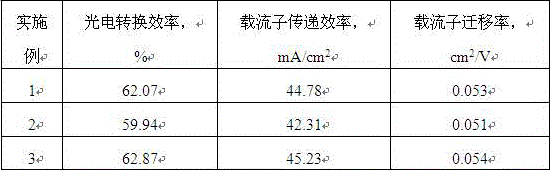

Examples

preparation example Construction

[0026] The preparation method of the high-performance broad-spectrum solar cell material comprises the following steps:

[0027] S1: 2,5-dichloro-β-acetylthiophene, 2-amino-5-mercapto-1,3,4-thiadiazole, trimethylolpropane, epoxy silane coupling agent, maleic anhydride The graft compatibilizer, acrylic acid bridging agent, and platinum catalyst are mixed evenly, and stirred for 2-4 hours at a microwave power of 200-300W, a temperature of 240-280°C, and a rotation speed of 400-600r / min to obtain a mixture A;

[0028] S2: Graphite, carbon black, silicon carbide, aluminum nitride, silicon nitride, aluminum oxide, silicon dioxide, bentonite, carbon fiber, boron fiber, carboxyethyl cellulose, dibasic lead phosphite, acrylate Class regulator, glycidoxypropyl trimethoxysilane, 701 powder, polyaluminum chloride, ethylene propylene rubber mixed, the microwave power is 250-360W, the temperature is 82-90°C, and the rotation speed is 500-700r / min Under stirring for 1-2h, mixture B was obt...

Embodiment 1

[0032] A high-performance broad-spectrum solar cell material, including the following raw materials in units of weight: 43 parts of 2,5-dichloro-β-acetylthiophene, 2-amino-5-mercapto-1,3,4-thiadiazole 23 parts, 6 parts of trimethylolpropane, 1.5 parts of epoxy silane coupling agent, 1.5 parts of maleic anhydride graft compatibilizer, 0.9 part of acrylic bridging agent, 0.1 part of platinum catalyst, 20 parts of graphite, carbon 24 parts of black, 5 parts of silicon carbide, 8 parts of aluminum nitride, 9 parts of silicon nitride, 8 parts of aluminum oxide, 6 parts of silicon dioxide, 5 parts of bentonite, 6 parts of carbon fiber, 4 parts of boron fiber, carboxyethyl 7 parts of cellulose, 0.9 parts of dibasic lead phosphite, 0.7 parts of acrylate regulator, 3 parts of glycidoxypropyltrimethoxysilane, 1.2 parts of 701 powder, 1 part of polyaluminum chloride, ethylene-propylene rubber 1.4 parts, 7 parts of bis(2,2,6,6-tetramethyl-4-piperidinate) sebacate, 4 parts of dibasic lead ...

Embodiment 2

[0039] A high-performance broad-spectrum solar cell material, including the following raw materials in units of weight: 38 parts of 2,5-dichloro-β-acetylthiophene, 2-amino-5-mercapto-1,3,4-thiadiazole 21 parts, 4 parts of trimethylolpropane, 1 part of epoxy silane coupling agent, 1 part of maleic anhydride graft compatibilizer, 0.6 part of acrylic bridging agent, 0.1 part of platinum catalyst, 15 parts of graphite, carbon 18 parts of black, 3 parts of silicon carbide, 5 parts of aluminum nitride, 6 parts of silicon nitride, 7 parts of aluminum oxide, 4 parts of silicon dioxide, 3 parts of bentonite, 4 parts of carbon fiber, 3 parts of boron fiber, carboxyethyl 5 parts of cellulose, 0.6 parts of dibasic lead phosphite, 0.5 parts of acrylate regulator, 2 parts of glycidoxypropyl trimethoxysilane, 0.8 parts of 701 powder, 0.7 parts of polyaluminum chloride, ethylene-propylene rubber 1.2 parts, 3 parts of bis(2,2,6,6-tetramethyl-4-piperidinate) sebacate, 2 parts of dibasic lead st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com