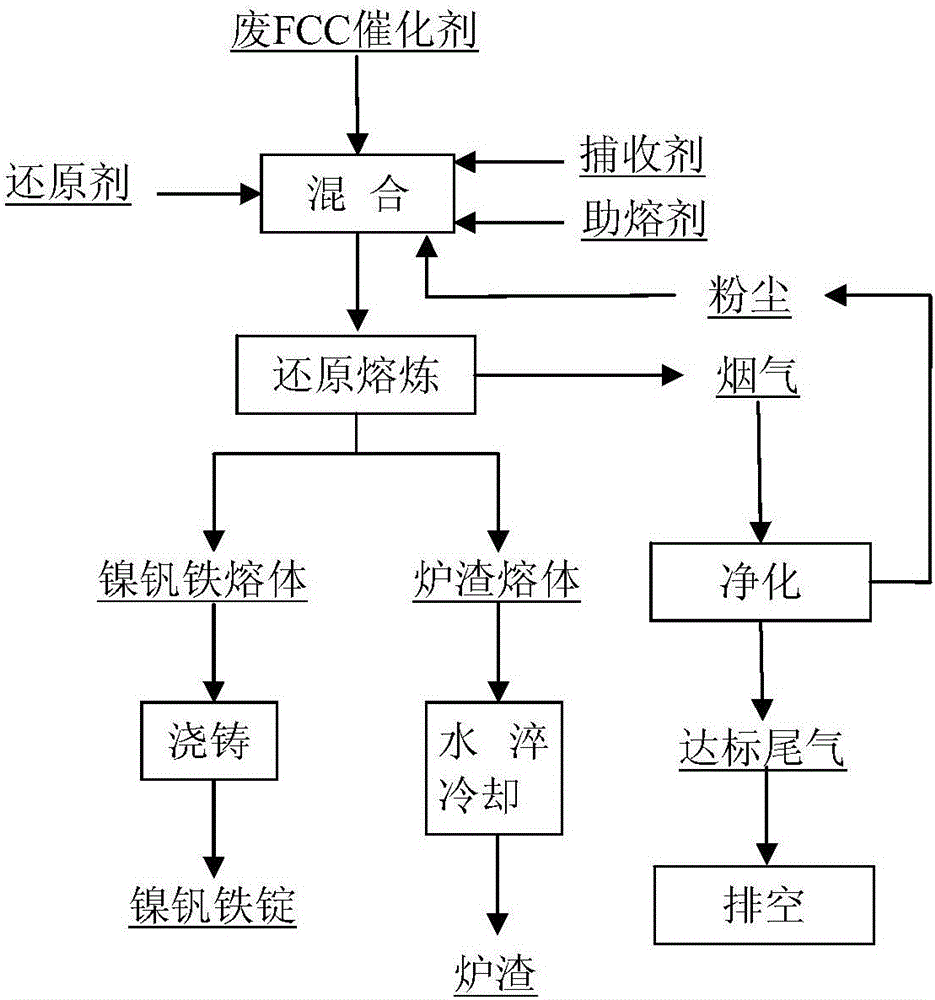

Method for recovering nickel and vanadium from waste FCC (fluid catalytic cracking) catalyst through reduction smelting

A catalyst, nickel-vanadium technology, applied in the field of harmless treatment of spent FCC catalysts, can solve the problems of difficult to achieve low-cost effective recycling, difficult iron solution treatment, high Si leaching rate, etc., to achieve low production costs and small environmental impact , The effect of strong regional adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for recovering nickel and vanadium by reduction smelting from waste FCC catalysts, using waste FCC catalysts discharged from a petroleum cracking plant in Shandong as raw material, the main elemental components of the waste FCC catalysts are shown in Table 1 below:

[0049] Table 1:

[0050] element Ni V Al 2 o 3

SiO 2

Fe Sb Ca content / % 1.30 0.27 46.00 51.00 0.46 0.36 0.23

[0051] The method comprises: taking 100g of the spent FCC catalyst, adding 6g of iron oxide concentrate with a mass fraction of 65% iron, 5g of anthracite, 20g of calcium oxide, and 5g of quartz sand, and mixing evenly to obtain a mixed material to be smelted. Put the mixed material to be smelted into a corundum crucible, cover the crucible lid, put the crucible containing the mixed material to be smelted into a high-temperature heating furnace, turn on the heating system, raise the melting temperature to 1550°C, and keep it warm for 60 minu...

Embodiment 2

[0054] A method for recovering nickel and vanadium by reducing smelting from waste FCC catalysts, using waste FCC catalysts discharged from a certain petroleum cracking plant in Hebei as raw material, the main elemental components of the waste FCC catalysts are shown in Table 2 below:

[0055] Table 2:

[0056] element Ni V al 2 o 3

SiO 2

Fe Sb Ca content / % 3.80 0.46 45.10 50.20 0.57 0.21 0.26

[0057] The method comprises: taking 100g of the spent FCC catalyst, adding 8g of iron filings, 3g of coke powder, 30g of limestone, and 8g of quartz sand, and mixing them uniformly to obtain a mixed material to be smelted. Put the mixed material to be smelted into a corundum crucible, cover the crucible lid, put the crucible containing the mixed material to be smelted into a high-temperature heating furnace, turn on the heating system, raise the melting temperature to 1575°C, keep it warm for 60 minutes, and then Cool naturally to norma...

Embodiment 3

[0060] A method for recovering nickel and vanadium by reduction smelting from waste FCC catalysts, using waste FCC catalysts discharged from a certain petroleum cracking plant in Gansu as raw material, the main elemental components of the waste FCC catalysts are shown in Table 3 below:

[0061] table 3:

[0062] element Ni V Al 2 o 3

SiO 2

Fe Sb Ca content / % 0.76 0.16 45.47 51.05 0.43 0.18 0.23

[0063]The method comprises: taking 100g of the spent FCC catalyst, adding 5g of magnetite with a mass fraction of 70% iron, 3g of charcoal, 25g of limestone, and 10g of quartz sand, and mixing evenly to obtain a mixed material to be smelted. Put the mixed material to be smelted into a corundum crucible, cover the crucible lid, put the crucible containing the mixed material to be smelted into a high-temperature heating furnace, turn on the heating system, raise the melting temperature to 1525 ° C, keep it for 90 minutes, and then Cool n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com