Method for preparing propylene glycol type antifreezing solution from natural lignocellulose raw materials

A technology of lignocellulose and propylene glycol, which is applied in hydrogenation preparation, hydroxyl elimination preparation, sugar derivative preparation, etc., can solve the problems of ethylene glycol toxicity, difficult separation of products, low reaction efficiency, etc. High price and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

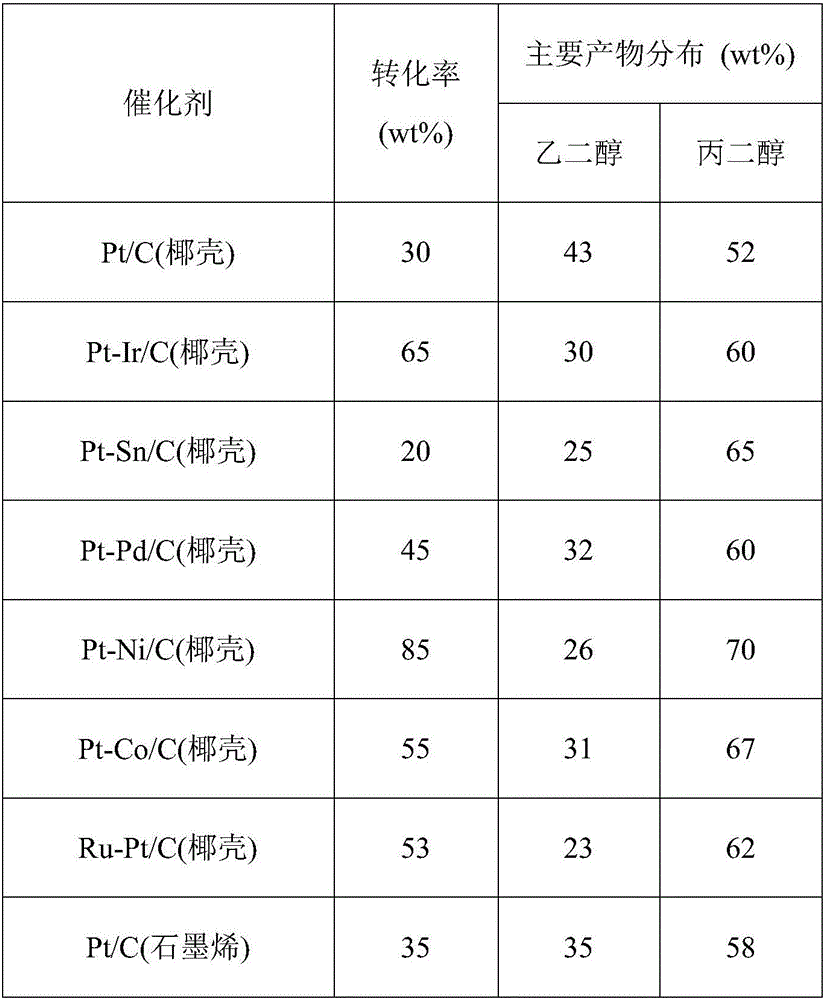

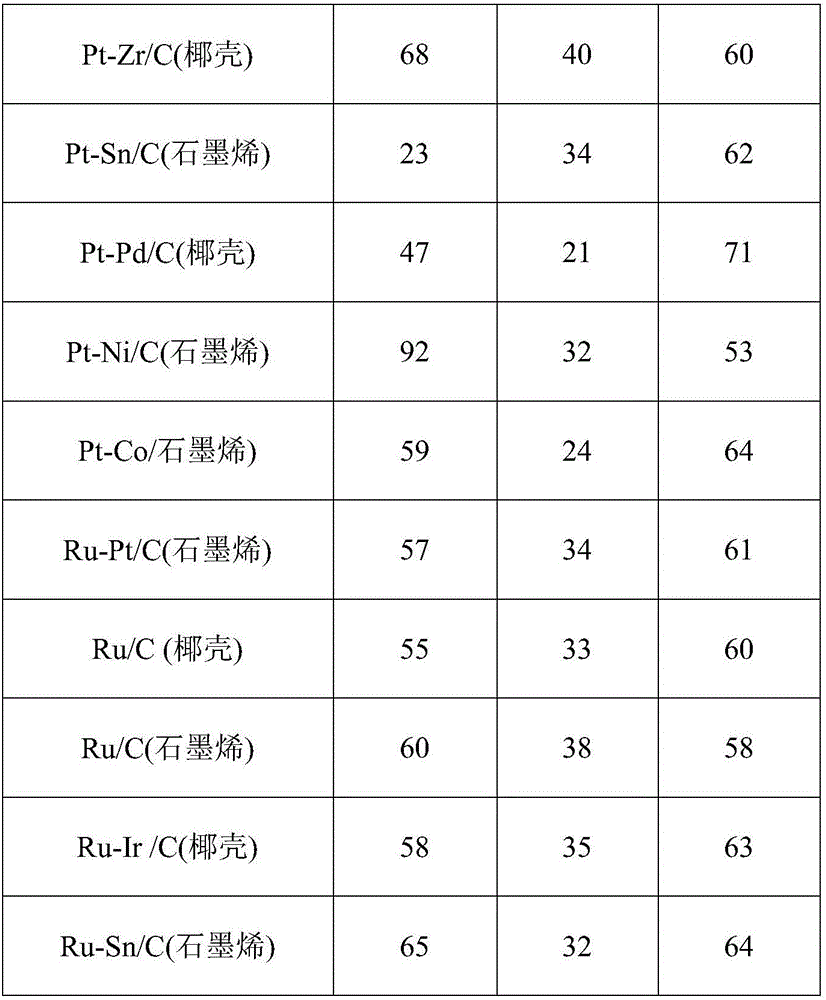

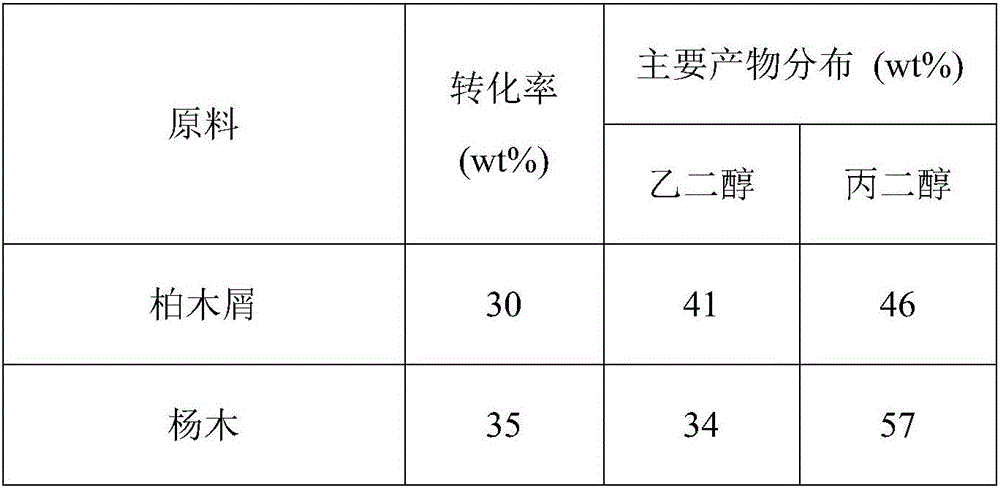

Examples

Embodiment 1

[0038] Pretreatment of natural lignocellulosic feedstock:

[0039] The straw is added into the NaOH solution, the NaOH solution is heated to 80° C., and the straw is heat-treated in the NaOH solution for 10 to 80 hours. adding the straw heat-treated in the NaOH solution into the triethylamine solution, heating the triethylamine solution to 90° C., and heat-treating the straw in the triethylamine solution for 100 h.

Embodiment 2

[0041] Weigh 2g of platinum tetrachloride and dissolve it in 50ml of deionized water, add an activated carbon carrier prepared from dried coconut shells, and add nickel nitrate at the same time, rotate and evaporate at room temperature until there is no water, and then place it in a vacuum drying oven for drying. Put the dried solid into the reaction kettle, and carry out reduction reaction with the incoming hydrogen, the reduction temperature is 350° C., and the reduction time is 4 hours, to obtain the catalyst Pt-Ni / C (coconut shell).

Embodiment 3

[0043] After mixing 40g of pretreated stalks and 100ml of water, add them to a slurry bed reactor, add 0.5g of catalyst Pt-Ni / C (graphene) at the same time, and feed 3MPa hydrogen; after heating to 240°C, The reaction was maintained for 1 h, nitrogen was replaced three times, and the stirring speed was 650 rpm to obtain a mixed solution mainly composed of propylene glycol; after the mixed solution was cooled to room temperature, the stirring was stopped and the gas was discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com