Coal tar pitch based carbon quantum dot green preparation and Fe<3+> detection method

A technology of coal tar pitch and carbon quantum dots, which is applied in measurement devices, fluorescence/phosphorescence, instruments, etc., can solve the problems of complex synthesis methods, unfriendly environment, expensive raw materials, etc., and achieves low price, good effect, and size distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

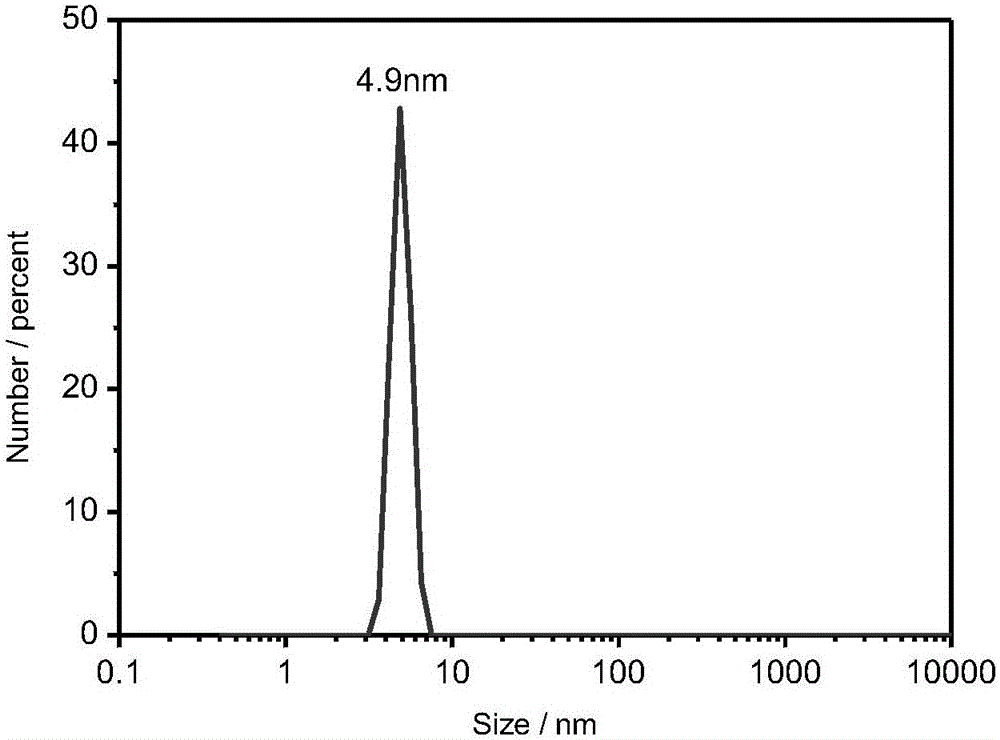

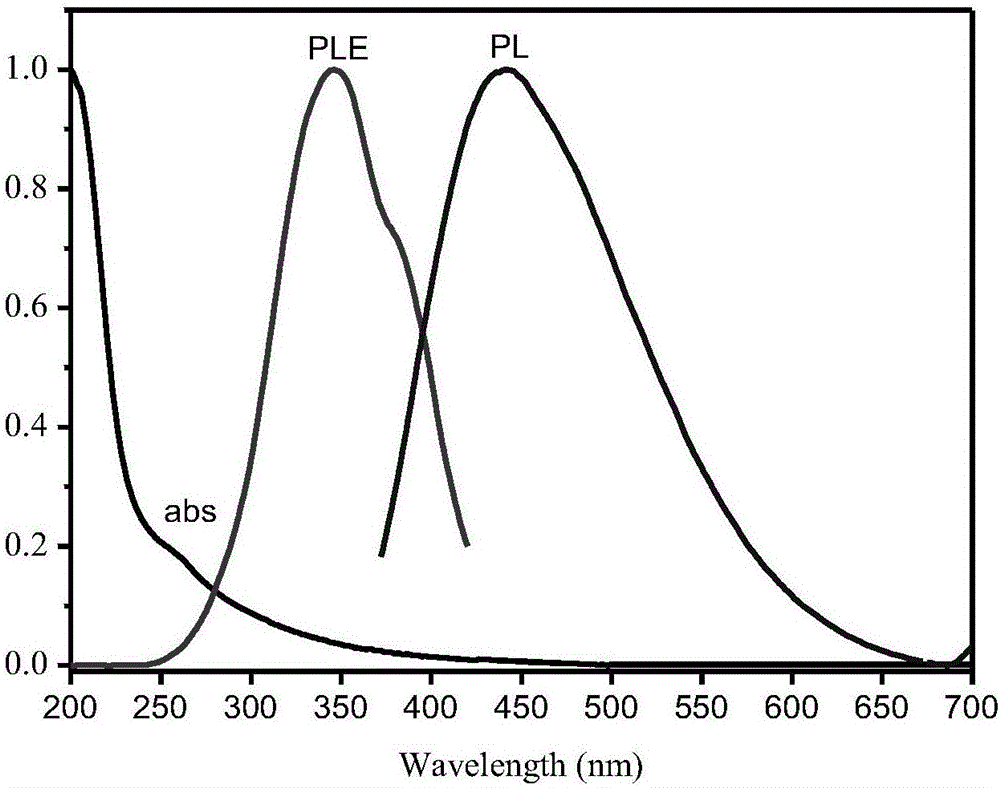

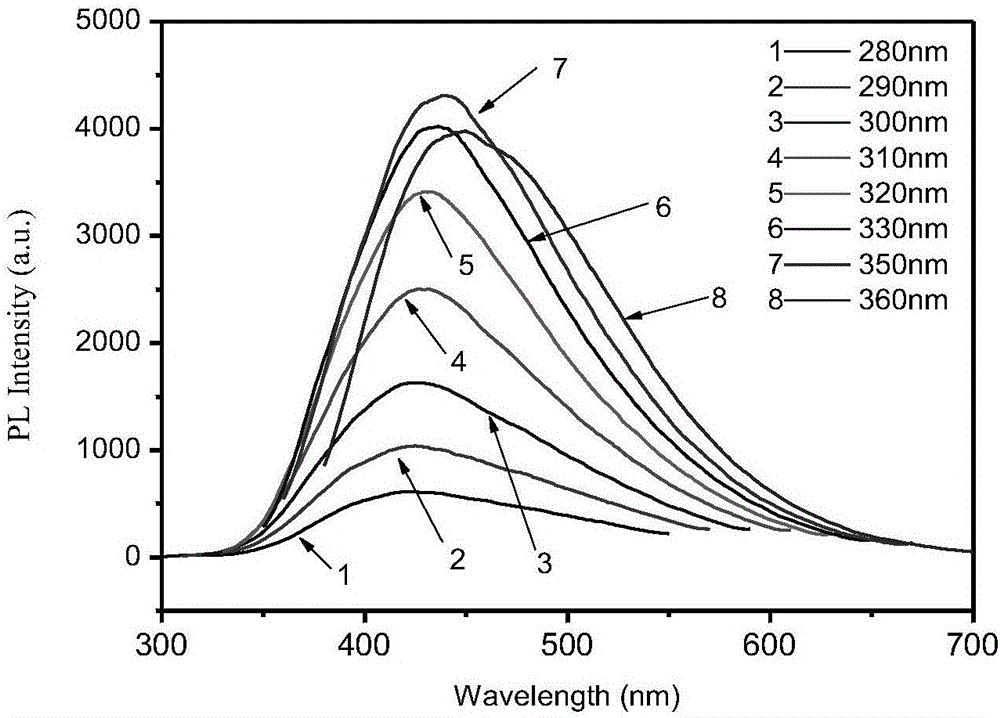

[0028] Weigh coal tar pitch 2g×4 at room temperature, add 60mL×4 (4 ball mill tanks) of deionized water for ball milling, ball mill for 4 hours at a speed of 500rpm / min, and then 100W ultrasonic dispersion for 1h, the dispersed After the suspension was subjected to O 3 Oxidation for 2h (concentration: 0.8L / min), and finally centrifuged at 15000rpm / min for 30min in a high-speed centrifuge to obtain a carbon quantum dot dispersion, and finally rotary evaporation and vacuum drying to obtain a solid carbon quantum dot.

Embodiment 2

[0030] Weigh coal tar pitch 2g×4 at room temperature, add 60mL×4 (4 ball mill tanks) of deionized water for ball milling, ball mill for 4 hours at a speed of 400rpm / min, and then 100W ultrasonic dispersion for 0.5h, the The dispersed suspension was subjected to O 3 Oxidation for 2h (concentration: 0.8L / min), and finally centrifuged at 15000rpm / min for 30min in a high-speed centrifuge to obtain a carbon quantum dot dispersion, and finally rotary evaporation and vacuum drying to obtain a solid carbon quantum dot.

Embodiment 3

[0032] Weigh coal tar pitch 2g×4 at room temperature, add 60mL×4 (4 ball mill tanks) of deionized water for ball milling, ball mill for 4 hours at a speed of 500rpm / min, and then 100W ultrasonic dispersion for 1h, the dispersed After the suspension was subjected to O 3 Oxidation for 1h (concentration: 0.8L / min), and centrifugation at 15000rpm / min for 30min in a high-speed centrifuge to obtain a carbon quantum dot dispersion, and finally rotary evaporation and vacuum drying to obtain a solid carbon quantum dot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com