Glucose isomerization molecular sieve catalyst and preparation method thereof

A molecular sieve and isomerization technology, applied in the field of glucose isomerization molecular sieve catalyst and its preparation, can solve the problems of long synthesis time, low glucose conversion rate, poor catalyst reusability, etc., and achieve short synthesis time and high glucose conversion rate. and fructose yield, good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of dealuminated molecular sieve

[0035] (1) With sodium metaaluminate as the aluminum source, silica sol as the silicon source, and TMAOH as the template, the hydrothermal synthesis method synthesizes Al-Beta zeolite; in the reaction mixture, there is Al in molar ratio 2 o 3 :SiO2 2 :TEAOH:H 2 O=1:50:18:1000;

[0036] (2) The obtained Al-Beta zeolite was mixed with 6mol L -1 HNO 3Mix according to the solid-liquid ratio of zeolite and acid at 1:30g / ml, reflux at 80°C for 6 hours, filter, wash until neutral, and dry at 100°C to obtain high-silica zeolite, which is recorded as : De-Al-Beta.

Embodiment 2

[0038] Preparation of Hierarchical Zeolite Molecular Sieves

[0039] (1) De-Al-Beta is used as the silicon source, and SnCl 4 ·5H 2 O is the tin source, 6g of De-Al-Beta and 0.42g of SnCl 4 ·5H 2 O was dissolved in TEAOH, stirred and mixed for 6h to form a sol; take 0.74g of NH 4 F was dissolved in 1.4g deionized water to form a solution, added dropwise to the above sol, stirred and mixed for 2 hours to form a viscous colloid; the obtained viscose was transferred to a hydrothermal synthesis kettle, and the first water After 24 hours of thermal crystallization, the Sn-Beta primary crystal was obtained, taken out, and cooled to room temperature for later use; in the first hydrothermal crystallization, the molar ratio of each substance was SiO 2 :SnO 2 :(TEA)O 2 :NH 4 F:H 2 O=1:0.012:0.27:0.2:7.5;

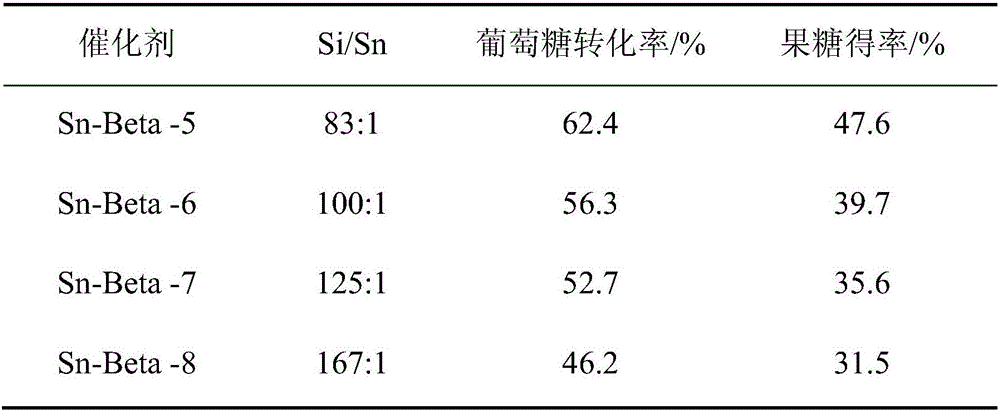

[0040] (2) Mix and dissolve the obtained Sn-Beta primary crystal with 8.74g of cetyltrimethylammonium bromide (CTAB) and 1.82g of tetramethylammonium hydroxide (TMAOH) in dei...

Embodiment 3

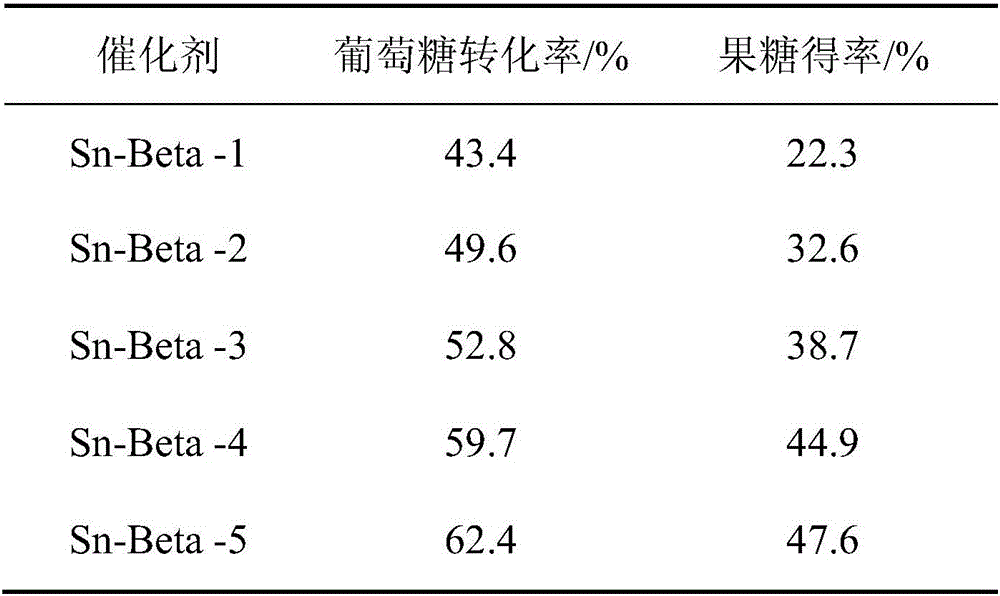

[0043] Preparation of Hierarchical Sn-Beta Molecular Sieves with Different Times of Acid Treatment

[0044] The Al-Beta molecular sieves synthesized in Example 1 were treated with nitric acid 1 to 5 times respectively, and were respectively denoted as De-Al-Beta-1, De-Al-Beta-2, De-Al-Beta-3, De-Al- Beta-4, De-Al-Beta-5;

[0045] The Al-Beta molecular sieves of different acid treatment times are prepared into different multi-stage Sn-Beta molecular sieves according to embodiment 2, denoted as: Sn-Beta-1, Sn-Beta-2, Sn-Beta-3, Sn-Beta -4, Sn-Beta-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com