High-quality coating solution applied to coated fabrics

A high-quality, coating liquid technology, applied in the direction of coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of increasing the incidence of accidents, heat resistance, flame retardancy, aging resistance, unstable surface resistance characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

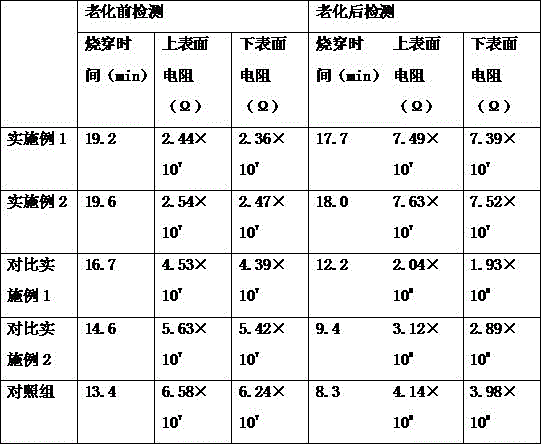

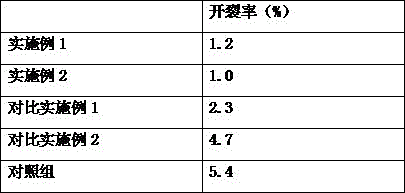

Examples

Embodiment 1

[0022] A high-quality coating solution for coated cloth, made of the following materials in parts by weight:

[0023] 42 parts of polyvinyl chloride, 16 parts of polytetrafluoroethylene, 6 parts of polyacrylate, 5 parts of epoxy resin, 4 parts of polyimide, 5 parts of functional additive powder, 1 part of stabilizer, 0.5 parts of plasticizer, 0.5 parts of thinner, 0.5 parts of antioxidant, 1 part of defoamer, 2 parts of propylene glycol methyl ether, 1.5 parts of methyl ethyl ketone; the functional additive powder is made of the following parts by weight: 36 parts of calcium carbonate , 16 parts of zeolite, 5 parts of zeolite, 4 parts of wood fish stone, 4 parts of boron carbide, 2 parts of carbon nanotubes, 2 parts of sodium dodecylbenzenesulfonate, 3 parts of octadecyl dimethyl ammonium chloride, 1 part of octadecyl dimethyl benzyl ammonium bromide, 5 parts of silane coupling agent, 4 parts of palm fiber.

[0024] Further, the stabilizer is magnesium stearate.

[0025] Fur...

Embodiment 2

[0037] A high-quality coating solution for coated cloth, made of the following materials in parts by weight:

[0038] 46 parts of polyvinyl chloride, 19 parts of polytetrafluoroethylene, 8 parts of polyacrylate, 7 parts of epoxy resin, 6 parts of polyimide, 7 parts of functional additive powder, 2 parts of stabilizer, 1 part of plasticizer, 1 part of thinner, 1 part of antioxidant, 2 parts of defoamer, 3 parts of propylene glycol methyl ether, 2 parts of methyl ethyl ketone; the functional additive powder is made of the following parts by weight: 40 parts of calcium carbonate , 19 parts of zeolite, 7 parts of zeolite, 6 parts of wood fish stone, 7 parts of boron carbide, 3 parts of carbon nanotubes, 4 parts of sodium dodecylbenzenesulfonate, 5 parts of octadecyl dimethyl ammonium chloride, 3 parts of octadecyl dimethyl benzyl ammonium bromide, 8 parts of silane coupling agent, 6 parts of palm fiber.

[0039] Further, the stabilizer is stearic acid file.

[0040] Further, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com