Nitrogen oxide fluorescent powder with garnet structure and preparation method and application thereof

A nitrogen oxide and phosphor technology is applied in the field of nitrogen oxide phosphor with a garnet structure and its preparation, which can solve the problems of unstable luminescence color, poor chemical stability, harsh preparation conditions, etc., and achieves high display efficiency. The effect of color index, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

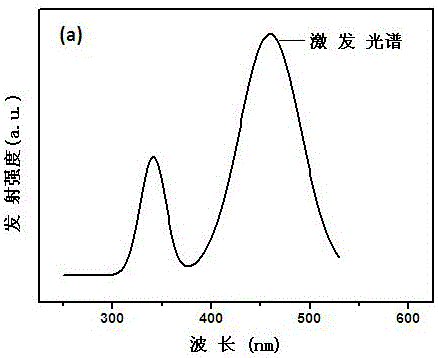

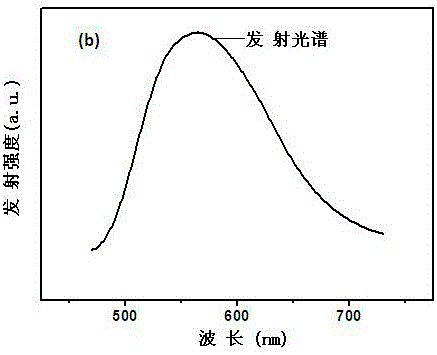

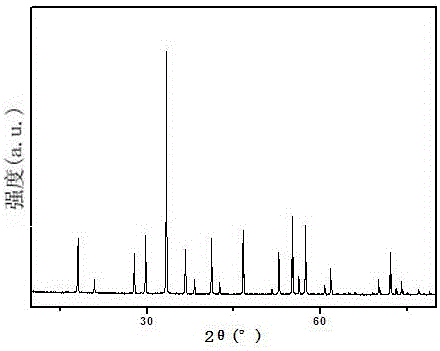

[0030] Example 1 MgY 1.94 al 3 Si 2 o 11 N:0.06Ce 3+ Phosphor powder preparation

[0031] According to the molecular formula MgY 1.94 al 3 Si 2 o 11 N:0.06Ce 3+ Weigh 0.2016 grams of magnesium oxide (MgO), 1.0952 grams of yttrium oxide (Y 2 o 3 ), 0.7647 grams of alumina (Al 2 o 3 ), 0.1754 grams of silicon nitride (Si 3 N 4 ), 0.3755 grams of silicon dioxide (SiO 2 ), 0.0516 grams of cerium oxide (CeO 2 ), the purity of the above raw materials is above 99%, and the above raw material mixture is fully ground in an agate mortar, so that the raw materials are mixed evenly, and the obtained precursor is placed in a corundum crucible. Under the reducing atmosphere provided by activated carbon, in the atmosphere In the furnace at 10°C·min -1The temperature was raised to 900°C at a constant speed, kept at a constant temperature for 6h, and then cooled to room temperature. The calcined precursor was ground again, in activated carbon and H 2 / N 2 (5% / 95%) put it in...

Embodiment 2

[0034] According to the molecular formula Mg 0.8 Ca 0.2 Y 1.97 Al 3 Si 2 o 11 N:0.03Ce 3+ Weigh 0.1612 grams of magnesium oxide (MgO), 0.1001 grams of calcium carbonate (CaCO 3 ), 1.1121 grams of yttrium oxide (Y 2 o 3 ), 0.7647 grams of alumina (Al 2 o 3 ), 0.1754 grams of silicon nitride (Si 3 N 4 ), 0.3755 grams of silicon dioxide (SiO 2 ), 0.0258 grams of cerium oxide (CeO 2 ), the purity of the above raw materials is above 99%. Thoroughly grind the above raw material mixture in an agate mortar to make the raw materials mix evenly. The obtained precursor was placed in a corundum crucible, under the reducing atmosphere provided by activated carbon, in an atmosphere furnace at 10 °C min -1 The temperature was raised to 900°C at a constant speed, kept at a constant temperature for 6h, and then cooled to room temperature. The calcined precursor was ground again, in activated carbon and H 2 / N 2 (5% / 95%) put it into the atmosphere furnace under the reducing at...

Embodiment 3

[0037] According to the molecular formula Mg 0.8 Ca 0.2 Y 1.44 Gd 0.5 Al 3 Si 2 o 11 N:0.06Ce 3+ Weigh 0.1612 grams of magnesium oxide (MgO), 0.1001 grams of calcium carbonate (CaCO 3 ), 0.8129 grams of yttrium oxide (Y 2 o 3 ), 0.9063 grams of gadolinium oxide (Gd 2 o 3 ), 0.7647 grams of alumina (Al 2 o 3 ), 0.1754 grams of silicon nitride (Si 3 N 4 ), 0.3755 grams of silicon dioxide (SiO 2 ), 0.0516 grams of cerium oxide (CeO 2 ), the purity of the above raw materials is above 99%. Thoroughly grind the above raw material mixture in an agate mortar to make the raw materials mix evenly. The obtained precursor was placed in a corundum crucible, under the reducing atmosphere provided by activated carbon, in an atmosphere furnace at 10 °C min -1 The temperature was raised to 900°C at a constant speed, kept at a constant temperature for 6h, and then cooled to room temperature. The calcined precursor was ground again, in activated carbon and H 2 / N 2 (5% / 95%) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com