Air purifying material capable of removing ammonia and secondhand smoke and preparation method thereof

An air purification material, second-hand smoke technology, applied in chemical instruments and methods, gas treatment, other chemical processes, etc., can solve problems such as limited actual effect and inappropriate use, etc., to achieve small wind resistance, well-developed pore structure, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

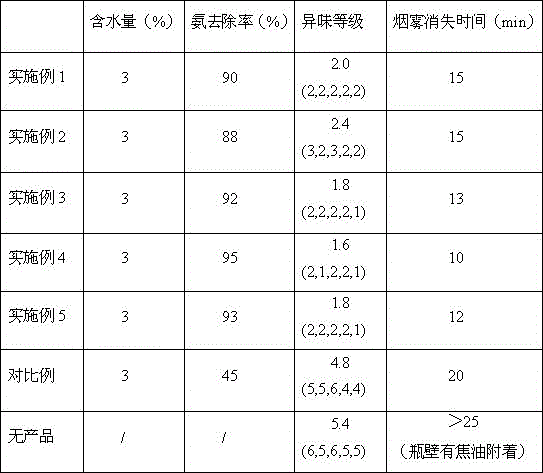

Examples

preparation example Construction

[0045] A preparation method of an air purification material capable of removing ammonia and second-hand smoke, comprising the following steps:

[0046] Step 1, first make the silica gel into a silica gel filter cake, and then make nano silica dry powder from this silica filter cake;

[0047] The preparation method of the silica gel cake is as follows: (1) The water glass solution with a mass concentration of 15% and the sulfuric acid with a mass concentration of 25% are injected into the bottom liquid at the same time according to the weight ratio of 1:0.25-0.5. In the kettle, and use ammonium bicarbonate as a reaction aid, control the reaction pH to be 8-9, and the reaction temperature to be 20-50 o C, the feeding time is 60min; (2) After adding water glass and sulfuric acid, keep the pH value and temperature, continue to react for 30min, and then raise the temperature to 80 o C Aging for 1.5 hours to promote the consolidation and strengthening of the silica colloidal struct...

Embodiment 1

[0059] 1500kg of water glass solution with a mass concentration of 15% and 550kg of sulfuric acid with a concentration of 25% were added dropwise to the reactor with 4000kg of deionized bottom liquid at the same time, and 1kg of reaction auxiliary ammonium bicarbonate was added to the reactor in advance, stirred and controlled. temperature is 35 o C, the pH value is 9, the feeding time is 60min, then keep the temperature and pH value to continue the reaction for 30min, then heat up to 80 o C aging 1.5h. After aging, add sulfuric acid dropwise to adjust the pH value to 7, and then put the material into the storage tank. When the material temperature drops to 60 o Below C, use a plate and frame filter press to wash and remove sulfate to obtain a silica gel filter cake. A part of the silica gel filter cake is directly flash-dried to obtain nano-silica dry powder.

[0060] Put 100 parts of silica filter cake, 0.15 parts of fatty alcohol polyoxyethylene ether, and 0.5 parts of ...

Embodiment 2

[0062] The preparation method of silica gel filter cake and nanometer silica dry powder is identical with embodiment 1.

[0063] Put 90 parts of silica filter cake, 0.3 parts of fatty acid glycerides, and 0.25 parts of sodium citrate into a high-speed cutting mixer, cut and mix into mud, and then put in 4 parts of activated carbon, 15 parts of nano silica gel dry powder, 1.5 parts of manganese dioxide, 2 1 part of aluminum oxide, 1.2 parts of iron oxide, 7 parts of aluminum hydroxide, 5 parts of magnesium hydroxide, and 0.8 part of hydroxyethyl cellulose, and continue to cut and mix rapidly for 8 minutes to obtain a fluffy wet material. A granulator with a mesh of 2mm was used for granulation. Then, the strip-shaped granular material is put into a spherical shot blasting machine for rounding to obtain a spherical granular material with a size of about 2 mm. Then, carry out the drying of material with airflow drying, drying temperature 100 o C, the drying time is 3 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com