A novel margarine and its preparation method and application

A margarine and oil technology, which is applied in the production/processing of edible oil/fat, can solve the problem of not being widely used, save time and energy consumption, improve shelf life and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

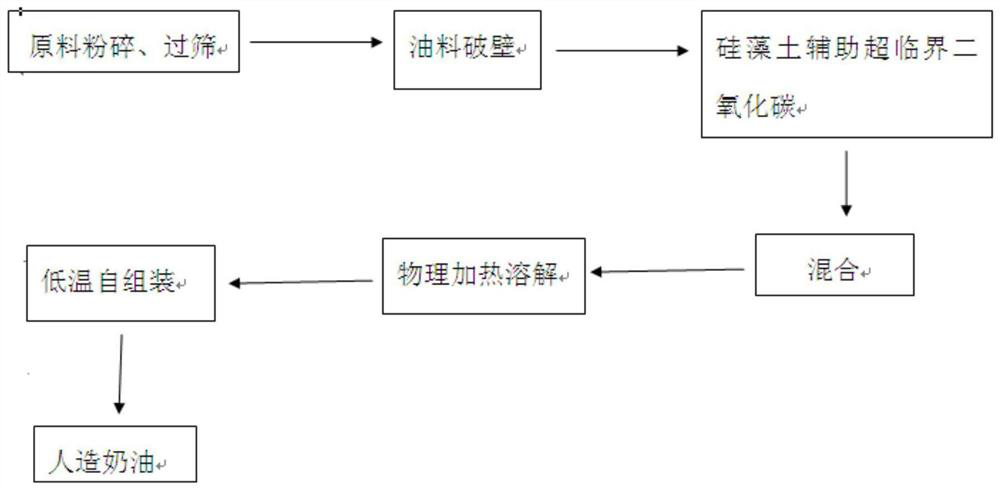

Method used

Image

Examples

Embodiment 1

[0029] Put fresh rice bran into a 1L extractor, and use carbon dioxide with a purity of 99% to boost the pressure of the extraction vessel to a pressure of 10MPa at a temperature of 20°C in the extraction vessel; after maintaining the pressure for 10 minutes, open the exhaust valve of the extraction vessel to quickly evacuate the carbon dioxide. Add the broken rice bran and diatomaceous earth into the extraction kettle with a mass ratio of 1:1, set the carbon dioxide temperature to 35°C, control the extraction pressure to 25MPa, separate the temperature to 40°C, and separate the pressure to 11MPa. 0.5h, the oil yield reached 92%.

[0030] Get 100g of rice bran oil obtained above, 5g of cinnamic acid, 2.5g of oryzanol, 2.5g of sterol, 5g of monoglyceride, 0.08g of lecithin, and 0.8g of sucrose ester. Dissolve in rice bran oil, add salt 0.05g, casein 2g, casein 1g, citric acid 0.05g, ethylenediaminetetraacetic acid disodium salt (EDTA 2 Na) 0.002g, sodium sorbate 0.07g, milk 16...

Embodiment 2

[0032] Novel artificial cream biscuit processing method

[0033] (1) Powder adjustment: mix 300g white sugar, 27g skimmed milk powder, 130g compound margarine, and 60g eggs, beat at medium speed for 2 minutes,

[0034] (2) Add 800g of low-gluten flour and beat at medium speed for 3 minutes

[0035] (3) After adding 2g of baking soda and 2g of table salt, mix at medium speed for 1min, then add 10g of water.

[0036] (4) Tablet pressing: use a noodle press to press into a dough sheet with a uniform thickness of 4 cm;

[0037] (5) Printing and forming: use various biscuit molds to print and form;

[0038] (6) Baking: Put the biscuit embryos neatly into the baking tray, control the temperature of the oven at 200°C, bake for 10 minutes, and cool to obtain biscuit products.

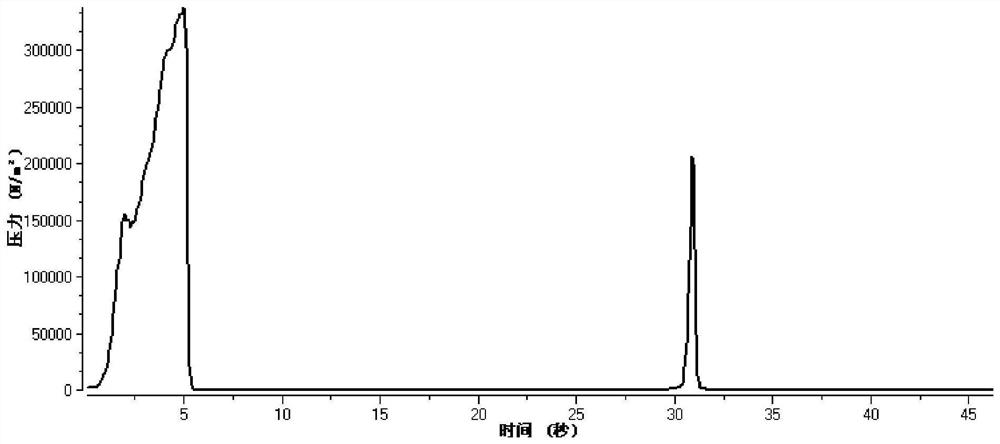

[0039] biscuit texture analysis see figure 1 . See Table 1 for sensory evaluation. The moisture content of the product is 2.9%, the acidity is 0.30%, the total number of colonies (cfu / g) <650, and the col...

Embodiment 3

[0041] Processing of new margarine crisp matcha biscuits

[0042] (1) Powder adjustment: Mix 180g of new margarine, 60g of matcha powder, 300g of white sugar, 30g of skimmed milk powder, 85g of eggs, mix and beat for 2 minutes at medium speed, add 40g of low-gluten flour, 1g of baking soda, 0.1g of salt, and knead fully Mix the dough and add 15g of water.

[0043] (2) Tablet pressing: use a noodle press to press into a dough sheet with a uniform thickness of 3 cm;

[0044] (3) Printing and forming: use various biscuit molds to print and form;

[0045] (4) Baking: Put the biscuit embryos neatly into the baking tray, control the temperature of the oven at 195°C, and bake for 18 minutes.

[0046] (5) cooling to obtain crispy matcha biscuits.

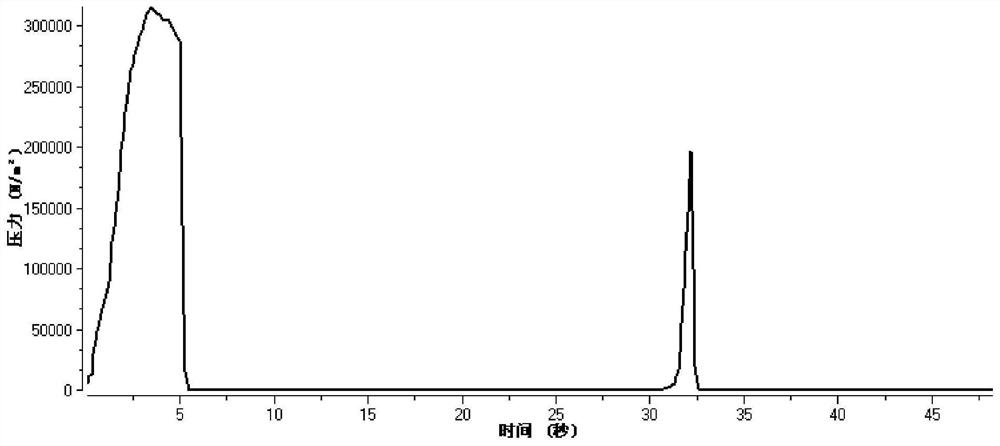

[0047] The resulting biscuits were subjected to texture analysis see figure 2 . See Table 1 for sensory evaluation. The water content of the product is 2.4%, the coliform bacteria (MPN / 100g) <30, and meets the national standard GB710...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com