Curing-stabilization chemical for restoring arsenic-polluted soil and preparation method and application of curing-stabilization chemical

A soil remediation and stabilization technology, applied in the field of soil remediation, can solve problems such as significant remediation effect, low arsenic pollution, and few soil remediation agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

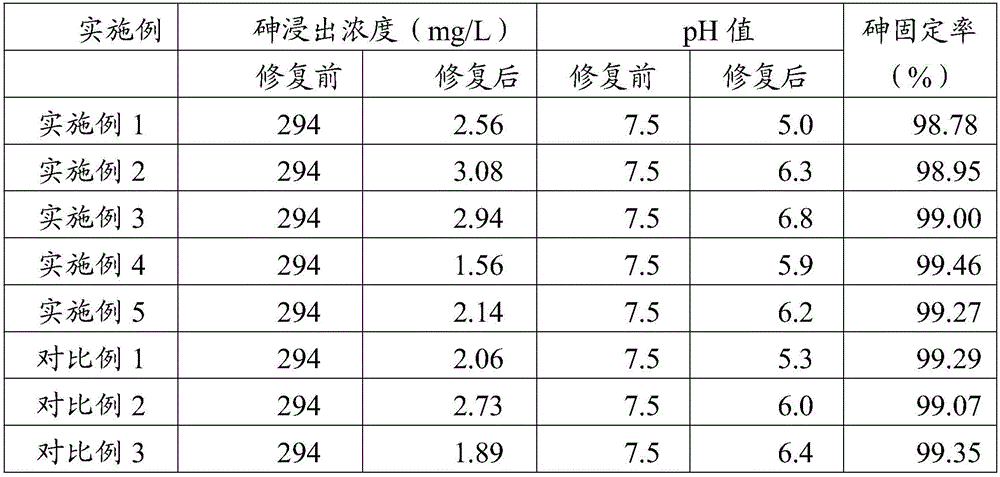

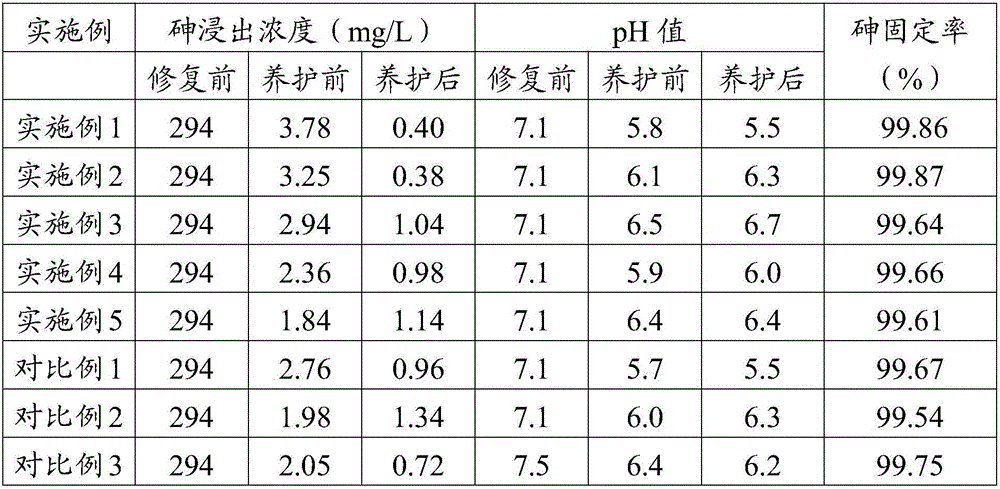

Examples

preparation example Construction

[0040] The present invention provides the preparation method of described curing-stabilizing agent, comprises the following steps:

[0041] The oxidizing agent, curing agent, stabilizer, additive and synergist are pulverized into powder with a particle diameter of 40-100 mesh, and stirred to obtain a curing / stabilizing agent.

[0042] In the present invention, the pulverization method is not particularly limited, and any pulverization method known to those skilled in the art can be used. The particle size of the pulverized powder is preferably 50-80 mesh, more preferably 60 mesh.

[0043] In the present invention, the stirring method is not particularly limited, and a stirring method well known to those skilled in the art can be used. The stirring speed is preferably 20-50 rpm, more preferably 30 rpm.

[0044] In the present invention, bagging is preferably carried out after the stirring. The charge amount is preferably 50-100kg / bag.

[0045] The invention provides the app...

Embodiment 1

[0049] Choose oxidizing agent to be lime, weigh its percentage by mass to be 15%; Choose curing agent to be fly ash, weigh its percentage by mass to be 20%; Choose stabilizing agent to be ferric chloride, weigh its percentage by mass to be 45%; Select The additive is polyferric sulfate, and its weight percentage is 10%; the synergist is humic acid, and its weight percentage is 8%. Lime, fly ash, ferric chloride, polyferric sulfate and humic acid were pulverized to obtain 50-mesh powder. Put the ground powder in five silos respectively; weigh and measure according to the ratio and send it to the mixing device by the belt conveyor; send it to the bagging and packaging device after mixing; use a forklift to transport the product Transport to warehouse for storage.

Embodiment 2

[0051] Choose oxidant as magnesium lime, weigh its mass percentage as 10%; choose solidifying agent as iron oxide and steel slag (mass ratio is 1:3), weigh its mass percentage as 40%; choose stabilizer as ferric chloride , sodium thiosulfate and sodium binitrite (mass ratio is 4:1:3), and its mass percent by weighing is 22%; Selecting additive is polyferric sulfate, polyferric chloride and ferrous chloride (mass ratio is 1:1:1), weighing its mass percentage as 35%; selecting the synergist as polyaspartic acid, weighing its mass percentage as 3%. Pulverize magnesium lime, iron oxide, steel slag, ferric chloride, sodium thiosulfate, sodium binitrite, polyferric sulfate, polyferric chloride, ferrous chloride, and polyaspartic acid to obtain 80-mesh powder . Put the ground powder in the silo respectively; weigh and measure according to the ratio and send it to the mixing device by the belt conveyor; send it to the bagging and packaging device after mixing; transport the product t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com