Method of preparing nano-silicon fungi type magnetic aerobic granular sludge and application

A technology of aerobic granular sludge and nano-silicon, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. Inhomogeneity, long-term use performance of aerobic granular sludge needs to be discussed and other issues, to achieve the effect of avoiding core disintegration, small particle size and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

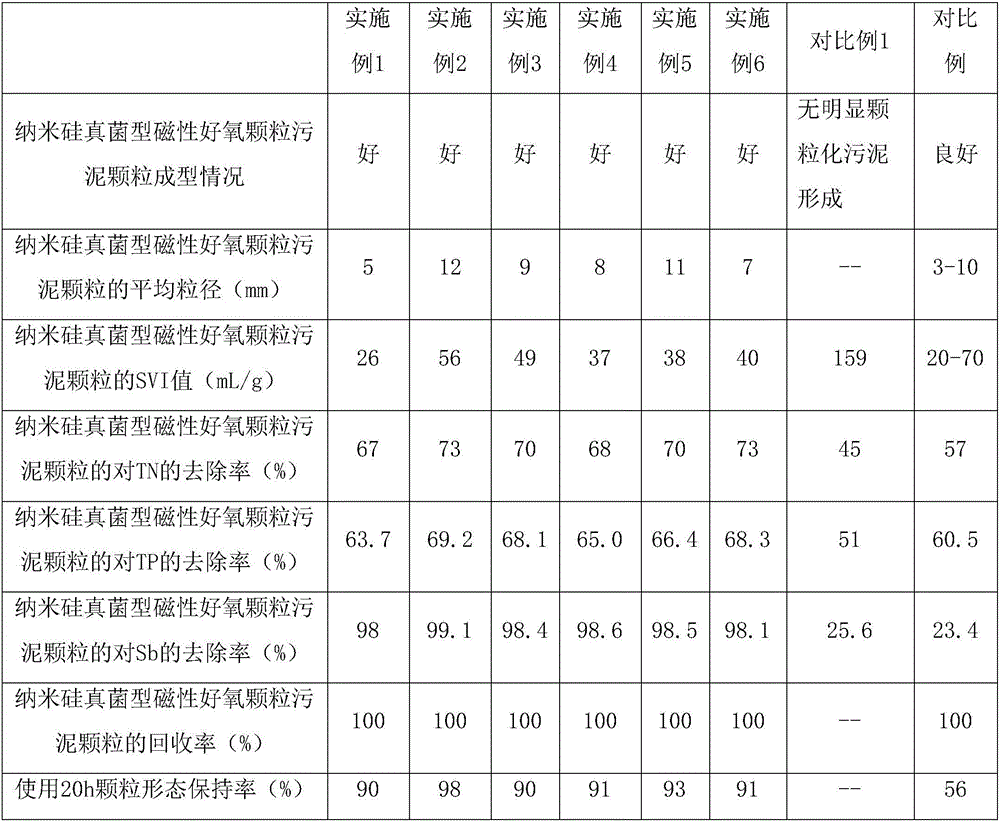

Examples

Embodiment 1

[0026] (1) Dissolve 0.02mol of ferric chloride and 0.01mol of ferric chloride as raw materials in 100ml of distilled water, stir for 1 hour under a nitrogen atmosphere, slowly add 10ml of concentrated ammonia water to adjust the pH value to 8.5-10, and cool to room temperature , after magnetic separation, repeated washing with distilled water to obtain ferric oxide nanospheres.

[0027] (2) Dilute 1g of iron ferric oxide nanospheres in a mixture of 20ml of distilled water, 60ml of absolute ethanol and 1.5ml of concentrated ammonia water, stir evenly, vibrate ultrasonically for 3 hours in a constant temperature water tank, and add 4.5-5ml dropwise Tetraethyl orthosilicate, continue magnetic stirring for 12 hours, use magnet to separate to obtain magnetic particles, wash the magnetic particles with absolute ethanol 3 times, dry and dry to obtain magnetic nanosphere ferric oxide / silicon dioxide.

[0028] (3) In the sequencing batch activated sludge reactor, the volume index SVI o...

Embodiment 2

[0032] (1) Dissolve 0.02mol of ferric chloride and 0.01mol of ferric chloride as raw materials in 100ml of distilled water, stir for 1 hour under a nitrogen atmosphere, slowly add 10ml of concentrated ammonia water to adjust the pH value to 8.5-10, and cool to room temperature , after magnetic separation, repeated washing with distilled water to obtain ferric oxide nanospheres.

[0033] (2) Dilute 1g of iron ferric oxide nanospheres in a mixture of 20ml of distilled water, 60ml of absolute ethanol and 1.5ml of concentrated ammonia water, stir evenly, vibrate ultrasonically for 3 hours in a constant temperature water tank, and add 4.5-5ml dropwise Tetraethyl orthosilicate, continue magnetic stirring for 12 hours, use magnet to separate to obtain magnetic particles, wash the magnetic particles with absolute ethanol 3 times, dry and dry to obtain magnetic nanosphere ferric oxide / silicon dioxide.

[0034] (3) In the sequencing batch activated sludge reactor, the volume index SVI of ...

Embodiment 3

[0038] (1) Dissolve 0.02mol of ferric chloride and 0.01mol of ferric chloride as raw materials in 100ml of distilled water, stir for 1 hour under a nitrogen atmosphere, slowly add 10ml of concentrated ammonia water to adjust the pH value to 8.5-10, and cool to room temperature , after magnetic separation, repeated washing with distilled water to obtain ferric oxide nanospheres.

[0039] (2) Dilute 1g of iron ferric oxide nanospheres in a mixture of 20ml of distilled water, 60ml of absolute ethanol and 1.5ml of concentrated ammonia water, stir evenly, vibrate ultrasonically for 3 hours in a constant temperature water tank, and add 4.5-5ml dropwise Tetraethyl orthosilicate, continue magnetic stirring for 12 hours, use magnet to separate to obtain magnetic particles, wash the magnetic particles with absolute ethanol 3 times, dry and dry to obtain magnetic nanosphere ferric oxide / silicon dioxide.

[0040] (3) In the sequencing batch activated sludge reactor, the volume index SVI o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com