Nanometer oxidized graphene modified epoxy type powder paint and preparation method thereof

A technology of epoxy resin and powder coating, which is applied in the field of coatings, can solve problems such as unsatisfactory dispersion effect, influence on paint film performance, and influence on powder coating electrostatic coating performance, so as to improve working environment conditions, increase dispersion effect, and mechanical strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

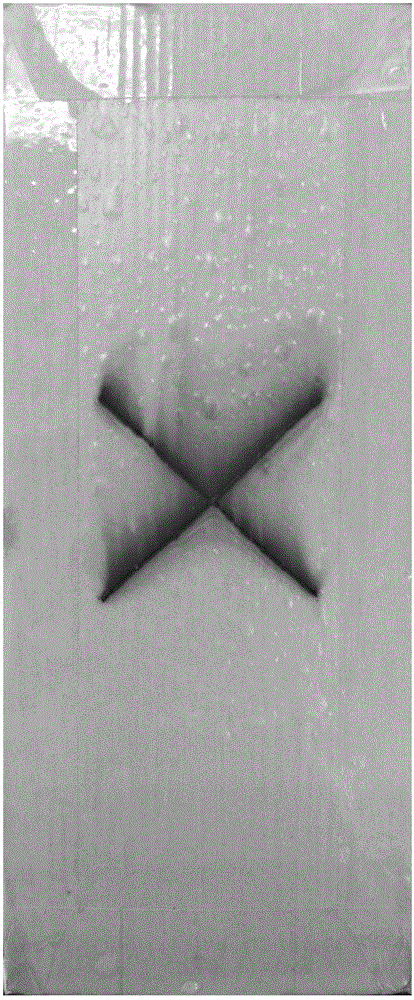

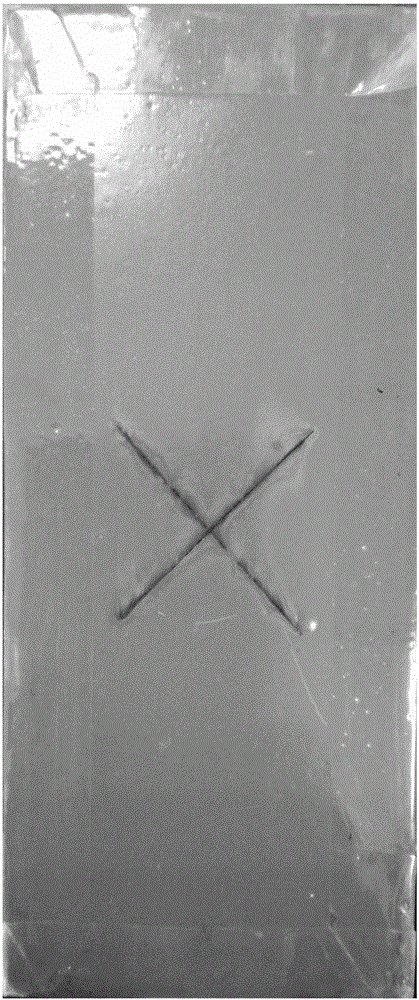

Image

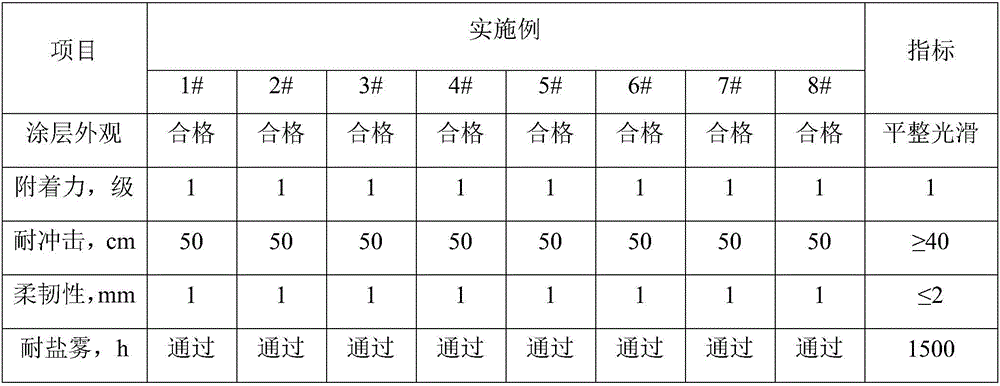

Examples

Embodiment 1

[0030] A nano-graphene oxide modified epoxy resin powder coating, firstly, 10 parts of graphene oxide, 30 parts of polyvinylpyrrolidone and 60 parts of bisphenol A epoxy resin are ground with a high-speed dispersant until the fineness reaches 35 microns Next, the graphene oxide pre-dispersed slurry was obtained. According to the weight ratio, 10 parts of graphene oxide predispersed slurry, 30 parts of bisphenol A epoxy resin, 40 parts of polyester resin, 5 parts of precipitated barium sulfate, 3 parts of fumed silica, ethylene glycol bis-trimellitic anhydride 5 parts, 3 parts of dibutyl phthalate, 1 part of polybutyl acrylate, 1 part of light stabilizer Tinuvin144, 1 part of iron black and 1 part of iron red are added to a twin-screw extruder for blending and extrusion. Finally, tableting, grinding, and separation are carried out to obtain finished products. Measure the central control indicators of nano-graphene oxide modified epoxy resin powder coatings, and pack them after...

Embodiment 2

[0032] A nano-graphene oxide modified epoxy resin powder coating, firstly, 20 parts of graphene oxide, 20 parts of DISPERBYK-130 and 60 parts of bisphenol A epoxy resin are ground with a high-speed dispersant until the fineness reaches 35 microns Next, the graphene oxide pre-dispersed slurry was obtained. According to the weight ratio, 1 part of graphene oxide predispersed slurry, 50 parts of bisphenol F epoxy resin, 30 parts of polyester resin, 1 part of light calcium carbonate, 2 parts of talcum powder, 5 parts of precipitated silica, 8 parts of dicyandiamide, 2 parts of dioctyl sebacate, 0.5 part of polylauryl acrylate and 0.5 part of a mixture of high-efficiency phosphite and phenolic antioxidant are added to a twin-screw extruder for blending and extrusion. Finally, tableting, grinding, and separation are carried out to obtain finished products. Measure the central control indicators of nano-graphene oxide modified epoxy resin powder coatings, and pack them after passing...

Embodiment 3

[0034] A nano-graphene oxide modified epoxy resin powder coating, firstly, 30 parts of graphene oxide, 20 parts of BYK-9076 and 50 parts of bisphenol F epoxy resin are ground with a high-speed dispersant until the fineness reaches 35 microns Next, the graphene oxide pre-dispersed slurry was obtained. According to the weight ratio, 5 parts of graphene oxide predispersed slurry, 30 parts of bisphenol F epoxy resin, 30 parts of polyester resin, 2 parts of mica powder, 8 parts of kaolin, 8 parts of ultrafine silica gel, 10 parts of tetramethoxymethylene glycoluril, 3 parts of dibutyl phthalate, 1 part of polyacrylate-2-ethylhexyl ester, 1 part of light stabilizer Tinuvin144, 0.5 parts of carbon black and 0.5 parts of ultramarine blue Twin-screw extruder blending extrusion. Finally, tableting, grinding, and separation are carried out to obtain finished products. Measure the central control indicators of nano-graphene oxide modified epoxy resin powder coatings, and pack them after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com