Quantum dot light emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve problems such as short life, low luminous efficiency, and unbalanced injection, and achieve good film formation and improved luminous efficiency. , Reduce the effect of injection energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

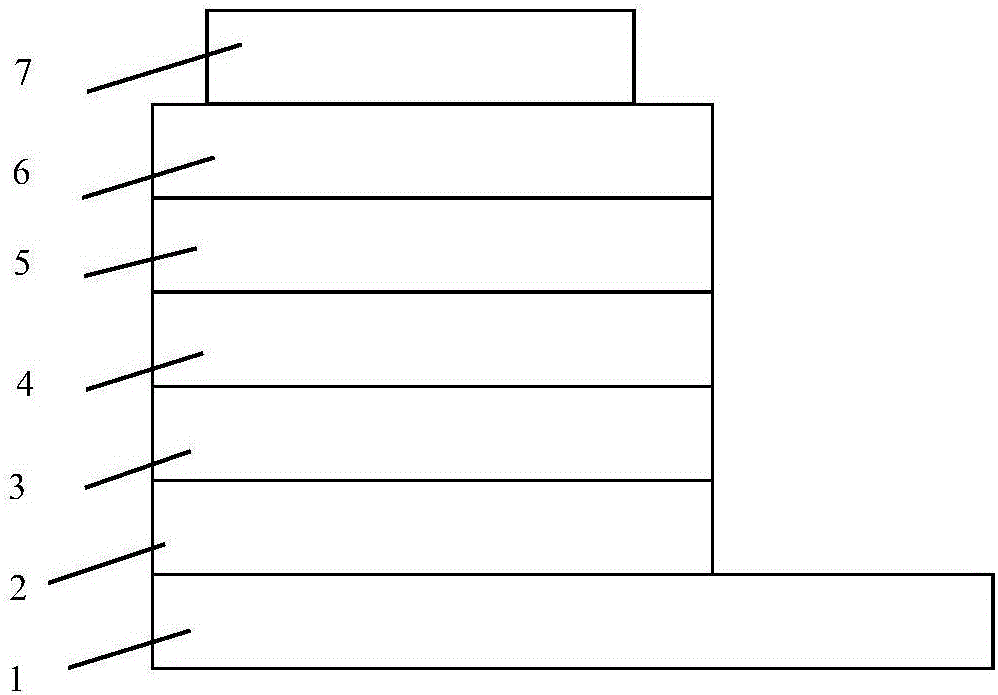

[0037] The present invention also provides a method for preparing the quantum dot light-emitting diode described in the above technical solution, comprising the following steps: sequentially depositing an anode modification layer, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electronic Transport layer and cathode; the anode modification layer is deposited by vacuum thermal evaporation.

[0038] In the present invention, the hole injection layer, hole transport layer, quantum dot light-emitting layer and electron transport layer are preferably deposited by spin coating.

[0039] In the present invention, the anode modification layer is vacuum thermally evaporated on the anode. In the present invention, the vacuum degree of the vapor deposition is preferably 5×10 -5 ~4×10 -4 Pa, more preferably 6~8×10 -5 Pa; In the present invention, the vapor deposition temperature is preferably 150-500°C, more preferably 200-400°C, more preferably 2...

Embodiment 1

[0051] In a vacuum of 5 x 10 -5 Pa, at a temperature of 300°C, vapor-deposit a polytetrafluoroethylene anode modification layer on an indium tin oxide anode with a thickness of 100 nm, and the thickness of the anode modification layer is 4 nm;

[0052] The following spin-coating processes were performed in an inert atmosphere of a glove box (O 2 2 O<1ppm):

[0053] Polyethylenedioxythiophene and polystyrene sulfonate were mixed at a molar ratio of 1:5, and a methanol solution was prepared at a concentration of 10mol / L, which was spin-coated at a speed of 6000r / s for 50s on the anode modification layer, and then at 150 Drying at ℃ for 30 minutes to obtain a hole injection layer with a thickness of 20 nm;

[0054] Spin-coat 10mg / mL PVK chlorobenzene solution on the surface of the hole injection layer, spin-coat at a rate of 3000r / s for 40s, put it in a vacuum drying oven at 120°C and dry for 20min to obtain a hole-transport layer with a thickness of 30nm;

[0055] Spin-coat 1...

Embodiment 2

[0061] In a vacuum of 4×10 -5 Pa, under the condition of 250°C, vapor-deposit an ethylene-tetrafluoroethylene copolymer anode modification layer on the silver nanowire anode with a thickness of 200nm, and the thickness of the anode modification layer is 6nm;

[0062] The following spin-coating processes were performed in an inert atmosphere of a glove box (O 2 2 O<1ppm):

[0063] Polyethylenedioxythiophene and polystyrene sulfonate were mixed at a molar ratio of 20:80, and an ethanol solution was prepared according to a concentration of 50mol / L, which was spin-coated at a speed of 7000r / s for 60s on the anode modification layer, and then at 150 Drying at ℃ for 25 minutes to obtain a hole injection layer with a thickness of 30 nm;

[0064] Spin-coat 8mg / mL poly-TPD chlorobenzene solution on the surface of the hole injection layer, spin-coat at a rate of 2500r / s for 40s, put it in a vacuum drying oven at 150°C for 10min, and obtain a hole transport layer with a thickness of 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com