Desulfurization wastewater zero discharge treatment system and method by utilizing flue gas and electrodialysis

A technology for desulfurization wastewater and treatment system, which is used in gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of difficult membrane cleaning, membrane fouling, increased energy consumption, etc. and corrosion, promoting CO2 emission reduction, and reducing the effect of treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

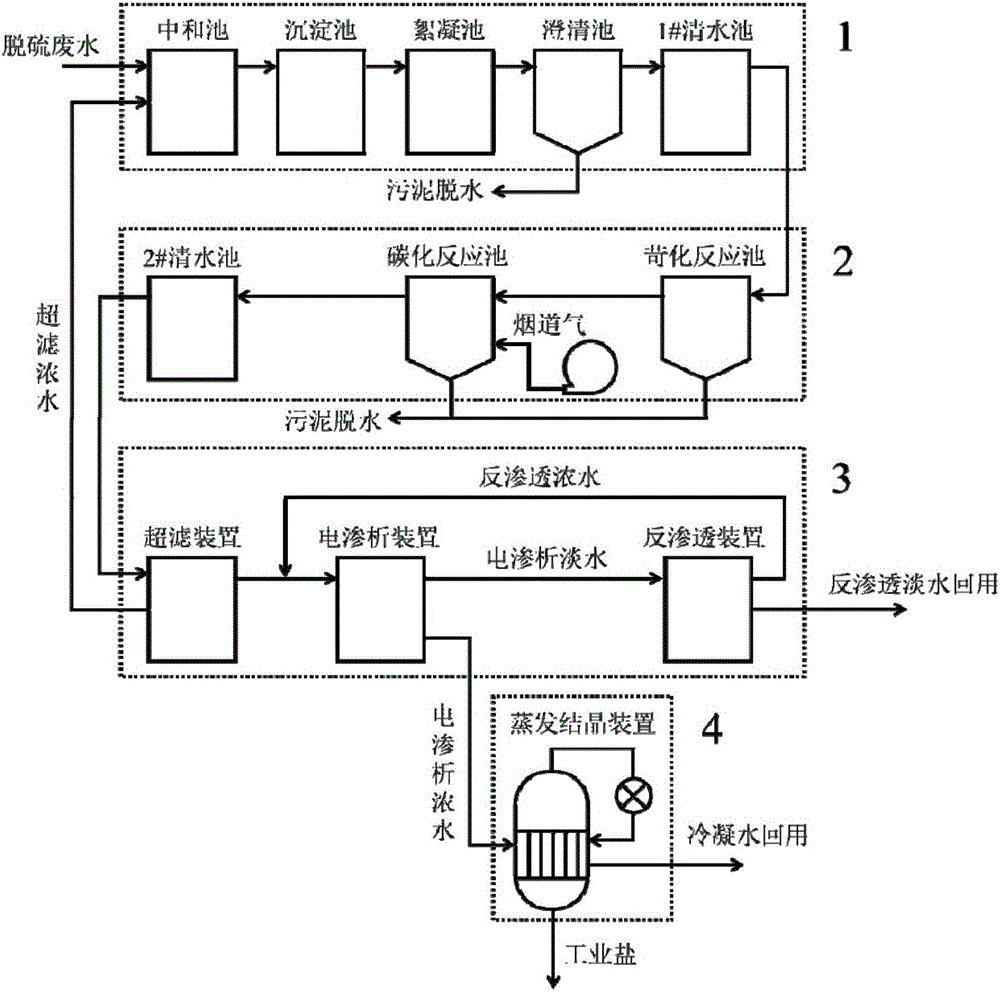

[0044] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The main components of desulfurization wastewater raw water are as follows: TDS 20000‐60000mg / L; SS 5000‐10000mg / L; SO 4 2‐ 2000‐6000mg / L; Ca 2+ 1500‐5000mg / L; Mg 2+ 3000‐6000mg / L. Such as figure 1 As shown, the desulfurization wastewater is passed into the chemical precipitation flocculation unit 1 for neutralization, precipitation, flocculation, and clarification treatment, and the precipitation flocculation reaction is carried out by adding lime milk, organic sulfur, polyferric sulfate chloride and polyacrylamide to obtain Clarified liquid according to the water quality requirements of power plant limestone-gypsum wet desulfurization wastewater water quality control index (DL / T 997-2006); the obtained clarified liquid is passed into lime-flue gas softening unit 2 for causticizing, carbonizing and clarifying treatment , by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com