Temperature-resistant and salt-resistant oil displacing polymer containing nano particles

An oil displacement polymer, heat-resistant and salt-resistant technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the cumbersome preparation process of functional monomers, affect product use and promotion, and poor polymerization activity of functional monomers and other issues, to achieve the effects of good compatibility, excellent temperature resistance, salt resistance, anti-aging, and small environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

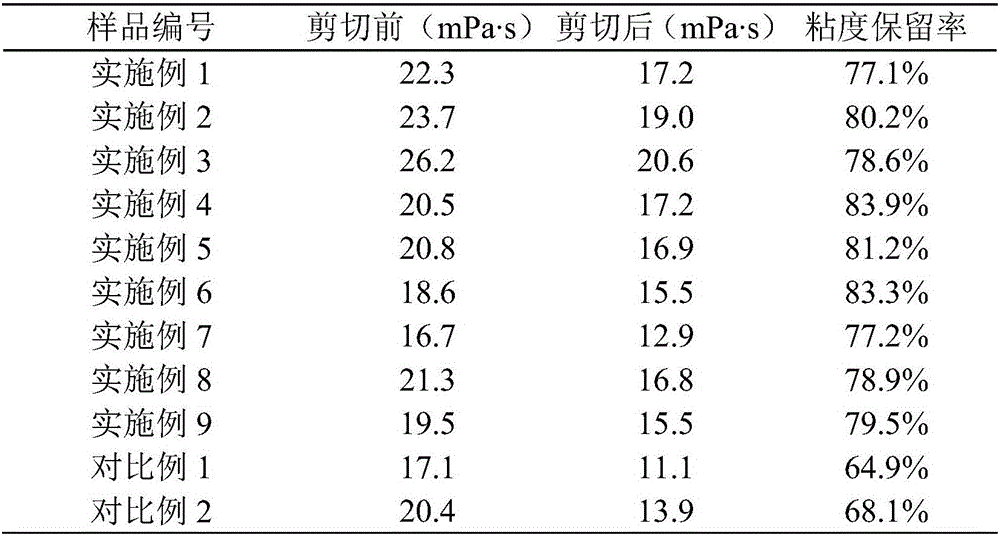

[0049] Example 1. Preparation of temperature-resistant and salt-resistant oil displacement polymer containing nanoparticles

[0050] Prepare the temperature-resistant and salt-resistant oil displacement polymer containing nanoparticles according to the following steps:

[0051] (1) Preparation of modified nano silica

[0052] Disperse the nano-silica and the silane coupling agent with amino group in the system of water:ethanol ratio of 1:9 (v / v), adjust the pH of the system to 8, reflux the reaction for 4 hours, filter the product and dry it to obtain Modified nano silica. The particle size of the nano-silica used is 80-100nm, and the concentration is 50g L -1 , the silane coupling agent with amino group is aminopropyltriethoxysilane, the concentration is 18g L -1 .

[0053] (2) Preparation of temperature-resistant and salt-resistant oil displacement polymer containing nanoparticles

[0054] 1g of the modified nano-silica prepared above, 30g of acrylamide, 20g of 2-acryla...

Embodiment 2

[0055] Example 2. Preparation of temperature-resistant and salt-resistant oil displacement polymer containing nanoparticles

[0056] As described in Example 1, the difference is that the particle size of the nano silicon dioxide in step (1) is 30-50nm, and the concentration is 45g L -1 .

Embodiment 3

[0057] Example 3, preparation of temperature-resistant and salt-resistant oil displacement polymer containing nanoparticles

[0058] As described in Example 1, the difference is that the silane coupling agent with amino groups in step (1) is N-aminoethyl-γ-aminopropyltrimethoxysilane, and the concentration is 25g L -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com