High-cycle nickel-cobalt-manganese ternary material and preparation method thereof

A ternary material, nickel-cobalt-manganese technology, used in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as poor compatibility and poor cycle performance, achieve good compatibility, improve rate performance, reduce side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

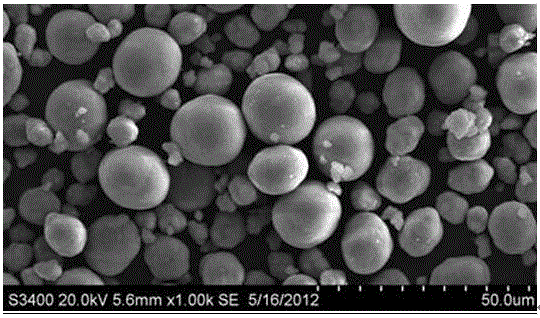

Image

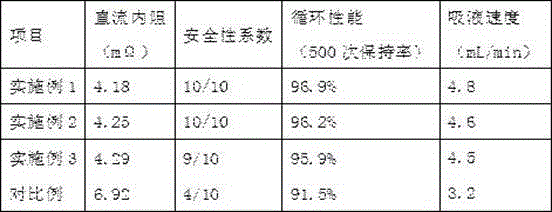

Examples

Embodiment 1

[0018] 1) First, weigh 15g of trimeric amine pyrophosphate and 3g of sodium dodecylbenzenesulfonate, add it to 500g of N-methylpyrrolidone, stir well to obtain a nitrogen-phosphorus mixture (referred to as solution A);

[0019] At the same time, weigh 3g of ethylene carbonate, add 1g of phenyllithium into 500g of N-methylpyrrolidone, and stir evenly to obtain a ethylene carbonate composite solution (referred to as B solution);

[0020] 2) After adding 120g LiNi 6 co 2 m 2 o 2 Add the ternary material to solution A, stir evenly, filter, and wash the obtained powder material into a tube furnace, and increase the temperature to 300°C at a heating rate of 8°C / min, and keep it warm for 2 hours, then naturally Cool down to room temperature to obtain a ternary composite material C doped with nitrogen and phosphorus in the cladding layer;

[0021] 3) After that, the composite material C was added to the solution B at a dew point of -40°C, stirred evenly, washed and filtered, and d...

Embodiment 2

[0023] 1) First weigh 10g of ammonium polyphosphate and 1g of sodium dodecylbenzenesulfonate, add them to 500g of N-methylpyrrolidone, stir well to obtain a nitrogen-phosphorus mixture (referred to as solution A);

[0024] At the same time, weigh 1g of ethylene carbonate, add 0.5g of n-butyllithium to 500g of N-methylpyrrolidone, and stir evenly to obtain a ethylene carbonate composite solution (referred to as B solution);

[0025] 2) After adding 100gLiNi 0.8 co 0.15 al 0.05 o 2 Add the ternary material to solution A, stir evenly, filter and wash the obtained powder material into a tube furnace, and increase the temperature to 200°C at a heating rate of 5°C / min, and keep it warm for 3 hours, then naturally Cool down to room temperature to obtain a ternary composite material C doped with nitrogen and phosphorus in the cladding layer;

[0026] 3) Afterwards, composite material C was added to solution B, stirred evenly, washed and filtered, and dried in a vacuum drying envir...

Embodiment 3

[0028] 1) First weigh 20g of melamine and 5g of sodium dodecylbenzene sulfonate, add them to 500g of N-methylpyrrolidone, and stir evenly to obtain a nitrogen-phosphorus mixture (referred to as solution A);

[0029] At the same time, 5g of ethylene carbonate was weighed, 2g of phenyllithium compound was added to 500g of N-methylpyrrolidone, and stirred evenly to obtain a ethylene carbonate composite solution (referred to as B solution);

[0030] 2) After that 150g120g LiNi 8 co 1 m 1 o 2 Add the ternary material to solution A, stir evenly, filter, and wash the obtained powder material into a tube furnace, and increase the temperature to 500°C at a heating rate of 10°C / min, and keep it warm for 1h, then naturally Cool down to room temperature to obtain a ternary composite material C doped with nitrogen and phosphorus in the cladding layer;

[0031] 3) Afterwards, composite material C was added to solution B, stirred evenly, washed and filtered, and dried in a vacuum drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com