Cyclodextrin supramolecular polymer/Fe3O4 magnetic nanoparticle complex

A technology of supramolecular polymers and magnetic nanoparticles, applied in alkali metal compounds, water/sludge/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the lack of selectivity and kinetics, separation and recovery difficulties and other problems, to achieve the effect of excellent adsorption capacity, simple operation and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

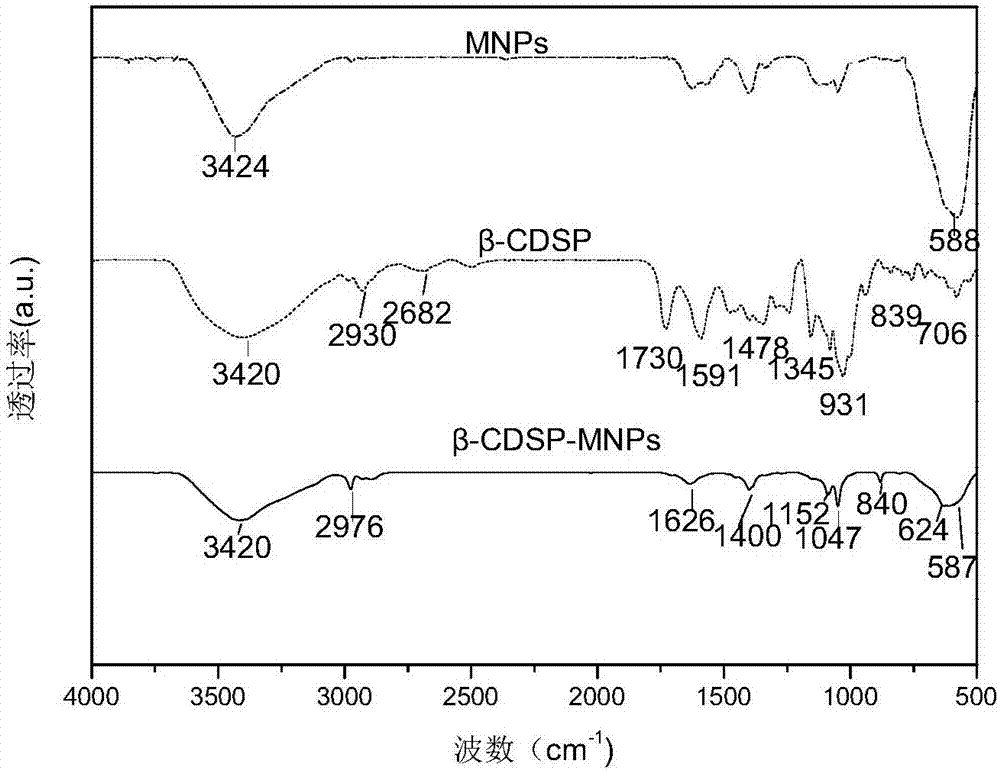

[0026] Embodiment 1: Preparation of β-CDSP-MNPs

[0027] (1) Preparation of β-CDSP: Add 2g of β-CD into 8mL dimethyl sulfoxide (DMSO) to dissolve and stir, then add 2mL of triethylamine, after 5 minutes, add 1.345g of cross-linking agent pyromellitic acid di anhydride (PMA), react at room temperature, and the reaction solution gradually gels. After 16 hours, the reaction was complete, and it became a block, which was ground with a mortar, washed with double distilled water and acetone, and filtered with suction, washed with secondary water three times, and freeze-dried to obtain a white powder β-CDSP.

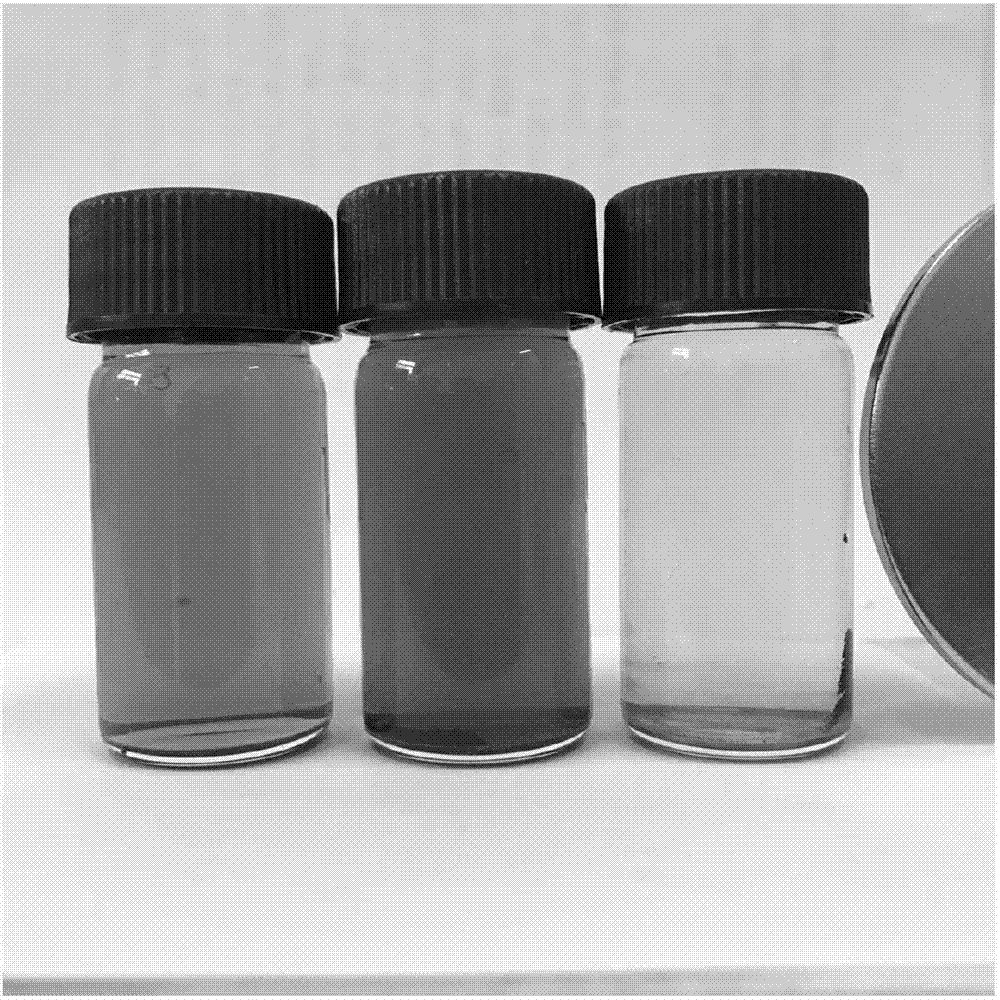

[0028] (2) Preparation of β-CDSP modified MNPs: 1 g FeCl 3 ·6H 2 O, 0.45g FeCl 2 4H 2 O and 0.9g β-CDSP are placed in the reactor, add 200mL of secondary water, heat and stir until dissolved under nitrogen protection, keep the temperature at 80°C for 5 minutes, add concentrated ammonia water dropwise to adjust the pH of the reaction solution to 10, and stir mechanically Af...

Embodiment 2

[0037] Example 2: Adsorption of β-CDSP-MNPs to malachite green dye

[0038] (1) Effect of pH on the adsorption performance of β-CDSP-MNPs

[0039] Determination of adsorption of malachite green (2×10 -5 M) Absorbance before and after to explore the effect of pH on the adsorption performance of β-CDSP-MNPs.

[0040] (2) Effect of ionic strength on the adsorption performance of β-CDSP-MNPs

[0041] The adsorption of malachite green (2×10 -5 M) Absorbance before and after to explore the effect of ionic strength on the adsorption performance of β-CDSP-MNPs.

[0042] (3) Malachite green standard curve and its linear range

[0043] Measure malachite green stock solution (2×10 -3 M) 2μL, 10μL, 20μL, 30μL, 40μL, 50μL, 60μL, 70μL, 80μL, 90μL, 100μL, dilute to 4mL with secondary water, measure the absorbance of the sample solution at 617nm. Draw the standard curve with the concentration (mol / L) of malachite green substance as the abscissa and the absorbance as the ordinate.

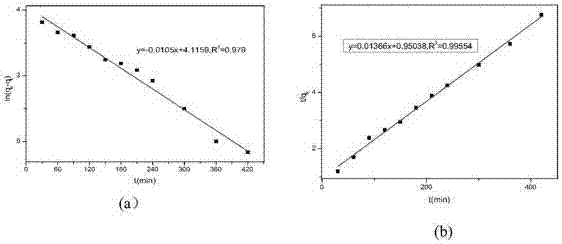

[00...

Embodiment 3

[0054] Embodiment 3: investigation of desorption and reuse situation

[0055] The complex uses absolute ethanol as the eluent, after ultrasonic oscillation for 10 minutes, hysteresis separation, and then washes three times with secondary water and absolute ethanol respectively, and vacuum-dries at 60°C to obtain the desorbed magnetic nanocomposite, which is then recycled. use. This cycle was repeated three times, and the adsorption amount of malachite green by β-CDSP-MNPs in each cycle was calculated.

[0056] Depend on Figure 13 It can be seen that after recycling 3 times, β-CDSP-MNPs still has a high adsorption capacity, indicating that β-CDSP-MNPs is a reusable dye adsorption material. It shows that the complex has a good application prospect in the field of dye pollutant adsorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com