An anti-pollution self-cleaning poly(vinylidene fluoride) flat-sheet ultrafiltration membrane, a preparing method thereof and applications of the membrane

A technology of polyvinylidene fluoride and polyvinylidene fluoride powder is applied in the field of anti-pollution self-cleaning polyvinylidene fluoride ultrafiltration membrane and its preparation, which can solve the problems of unimproved structure and performance, and avoid agglomeration and difficult separation. , Improve the effect of anti-pollution self-cleaning performance and economical improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation raw materials of the ultrafiltration membrane include the following components: polyvinylidene fluoride powder, amphiphilic copolymer, organic solvent, attapulgite-graphite-like phase carbon nitride composite material powder, additives, and coagulation bath.

[0043] The organic solvent here refers to a solvent capable of dissolving polyvinylidene fluoride powder, for example: N-methyl-2-pyrrolidone, tetrahydrofuran, dimethyl sulfoxide; amides such as dimethylacetamide and dimethylformamide; Ester solvents such as trimethyl phosphate or triethyl phosphate; Lactone solvents such as γ-butyrolactone; and their mixed solvents.

Embodiment 1

[0051] Example 1 Preparation of attapulgite-graphite-like phase carbon nitride composite material

[0052] Weigh 3.02g of silane coupling agent-modified attapulgite and disperse it in 1000mL of deionized water, ultrasonically disperse; then add 6.01g of melamine, stir, condense and reflux at 80°C for 2h; then freeze-dry for 48h, grind and add to the quartz boat , the quartz boat was placed in the tube furnace, and the temperature was programmed in the tube furnace under the air atmosphere. The temperature rise program was as follows: room temperature was raised to 500 °C for 0.5 h, kept at 500 °C for 2 h, then continued to be heated to 520 °C for 2 min, and kept After 2 hours, the temperature was naturally lowered, and it was fully ground to a powder form to obtain an attapulgite-graphite-like phase carbon nitride composite material (for the preparation method, refer to patent document CN106179447A).

Embodiment 2

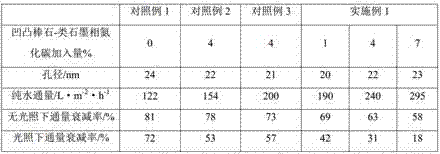

[0054] Add 1%, 4%, and 7% (relative to the quality of polyvinylidene fluoride powder) of the attapulgite-graphite-like carbon nitride prepared in Example 1 into 48g of triethyl phosphate, and the ultrasonic dispersion is uniform Finally, add 12g of polyvinylidene fluoride powder and 3% poly(methyl methacrylate-vinyl alcohol) (relative to the mass of polyvinylidene fluoride powder) and stir and dissolve at 80°C for 24h, then add 3g of polyethylene difluoride Stir with alcohol 400 for 24 hours to obtain the casting solution, and stand at 80 ° C for 24 hours to obtain the casting solution; then use a scraper to apply the casting solution on the flat plate, and use the immersion precipitation phase inversion method to form a film, the coagulation bath is the mass fraction 0.05% attapulgite-graphite-like phase carbon nitride aqueous suspension, the water temperature is 25°C, and the anti-pollution self-cleaning attapulgite-graphite-like phase carbon nitride / polyvinylidene fluoride u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com