Tin-molybdenum codoped titanium dioxide nanotube array electrode and preparation method

A technology of nanotube array and titanium dioxide, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of increasing the preparation process, achieve the expansion of application range, convenient preparation, and realization of inorganic Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Polish the Ti sheet with sandpaper until the surface is smooth, then immerse it in acetone, isopropanol, and absolute ethanol solution for ultrasonic treatment for 15 minutes to remove oxides and oil on the surface of the Ti sheet, then rinse it with deionized water, and dry it with nitrogen gas for later use ;

[0027] 2. The mass fraction is 3.5wt% NH 4 F was dissolved in deionized water with a volume ratio of 10:8:1, 65% concentrated nitric acid, and analytically pure hydrofluoric acid mixed solution to prepare an etching solution, and the Ti sheet prepared in 1 was placed in the etching solution Etch for 30s, then rinse with deionized water, and blow dry with nitrogen for later use;

[0028] 3. Na 2 SnO 3 ·3H 2 O, Na 2 MoO 4 ·H 2 O and 0.5 wt% NH 4 F was dissolved in an ethylene glycol-water mixed solution with a volume ratio of 24:1, stirred and mixed evenly to prepare an electrolyte solution, the molar concentration of Sn in the solution was 0.01mol / L, ...

Embodiment 2

[0033] This embodiment differs from Example 1 in that the molar concentration of Sn in the prepared electrolyte solution is 0.05 mol / L, and the molar concentration of Mo is 0.05 mol / L.

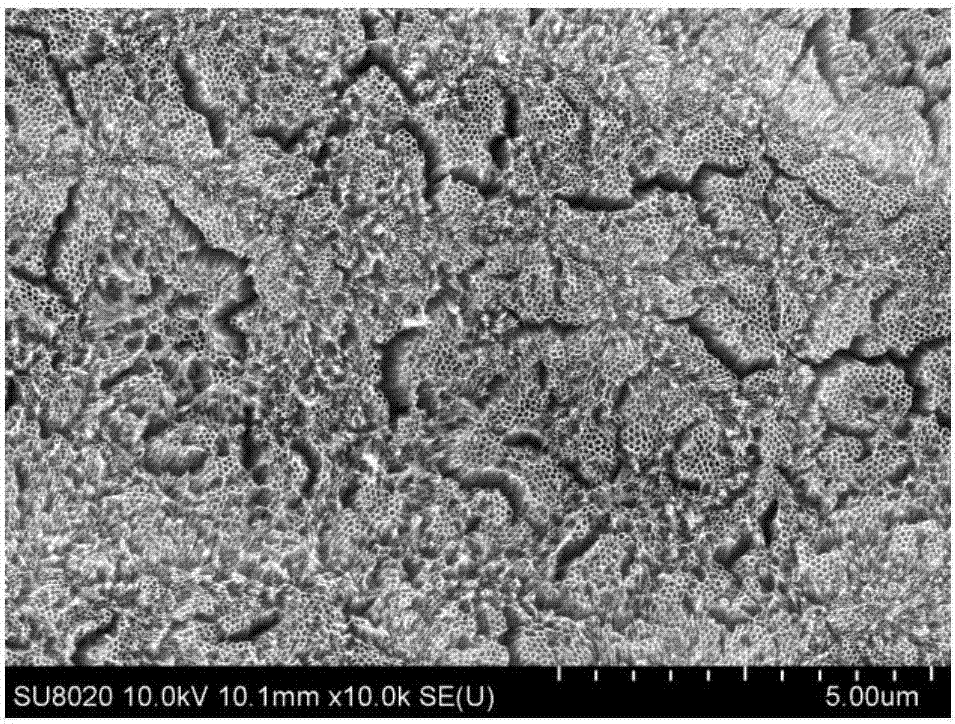

[0034] Scanning electron microscope (SEM) test: for the prepared Sn-Mo-TiO 2 - The surface morphology of NTs / Ti electrode was characterized and tested, the results are as follows figure 1 shown.

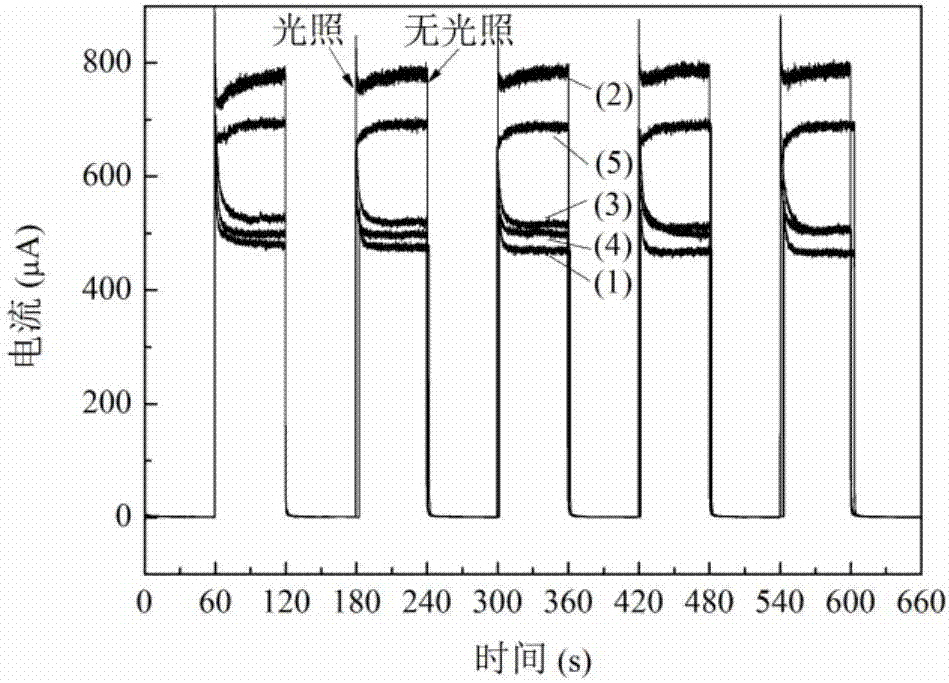

[0035] Photoelectric performance test: Sn-Mo-TiO 2 -NTs / Ti electrode as working electrode, platinum sheet as counter electrode, Hg / Hg 2 SO 4 The electrode is the reference electrode, with 0.05mol / L Na 2 SO 4 As an electrolyte solution, a 300W xenon lamp equipped with an AM 1.5 simulated sunlight reflector was used as a light source, and the photoresponse ability of the electrode was measured by chronoamperometry under an external bias voltage of 0.5V. The maximum photoresponse current measured under light conditions is 780μA, such as figure 2 Curve (2) shows.

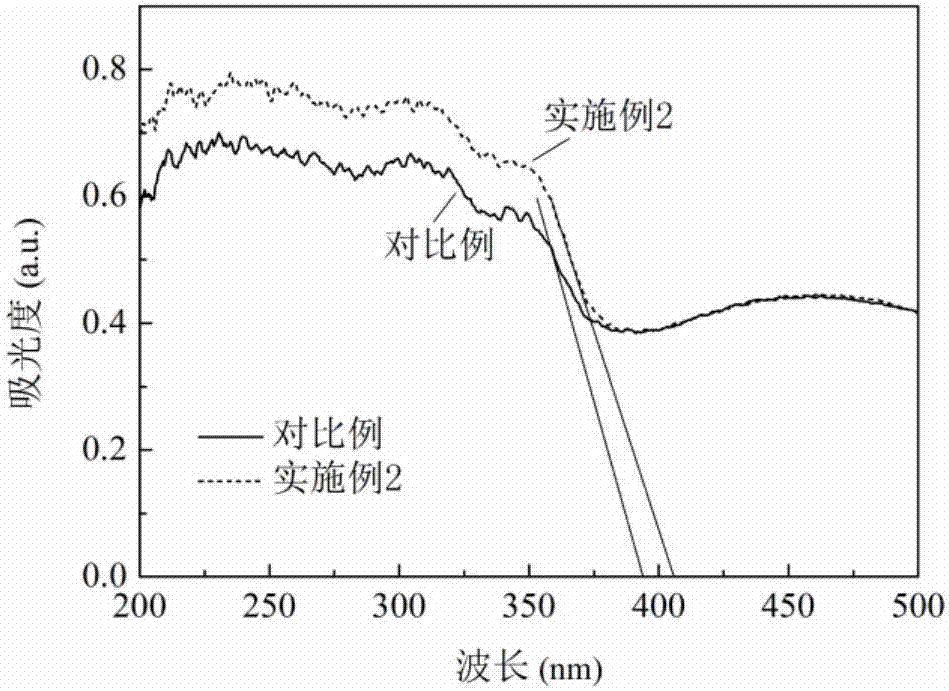

[0036] UV-Vis Diffuse Reflecta...

Embodiment 3

[0038] The difference between this embodiment and Example 1 is that the molar concentration of Sn in the prepared electrolyte solution is 0.05 mol / L, and the molar concentration of Mo is 0.1 mol / L.

[0039] Photoelectric performance test: Sn-Mo-TiO 2 -NTs / Ti electrode as working electrode, platinum sheet as counter electrode, Hg / Hg 2 SO 4 The electrode is the reference electrode, with 0.05mol / L Na 2 SO 4 As an electrolyte solution, a 300W xenon lamp equipped with an AM 1.5 simulated sunlight reflector was used as a light source, and the photoresponse ability of the electrode was measured by chronoamperometry under an external bias voltage of 0.5V. The maximum photoresponse current measured under light conditions is 514μA, such as figure 2 Curve (3) shows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com