Pd catalyst supported by nitrogen-doped carbon material and preparation method thereof and application thereof in nitrobenzene catalytic hydrogenation reaction

A nitrogen-carbon material and catalyst technology, which is applied in the field of nitrogen-doped carbon material-supported Pd catalyst and its preparation, nitrobenzene catalytic hydrogenation reaction, can solve the problems of high reaction temperature, insufficient aniline selectivity, slow reaction, etc. Mild conditions, excellent catalytic activity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0033] Add 20ml of absolute ethanol, 0.2ml of toluene (internal standard), 0.6g of nitrobenzene, and 4mg of catalysts loaded with Pd on different carriers into the autoclave in turn, stir and heat to 45°C, inject hydrogen, start timing, and During the reaction process, the pressure was maintained at 0.5 MPa. After 1.5 hours of reaction, the timing was stopped, the reactor was cooled to room temperature, and the liquid-solid phase mixture was filtered to obtain a solid catalyst and a liquid phase mixture containing unreacted reactants and reaction products. The liquid phase mixture was detected and analyzed by gas chromatography (GC).

Embodiment 1

[0034] The preparation process of the catalyst used in Example 1 is as follows: ultrasonically disperse 200 mg of carbon nanotubes in 20 ml of deionized water, then add 2.76 ml of 6.08 mg / ml palladium chloride solution, adjust the pH value to 8.5, and then add 10mg / mlNaBH 4 The solution was 5ml, stirred for 8h, filtered, washed, vacuum-dried, and ground to obtain a carbon nanotube-loaded Pd catalyst.

Embodiment 2

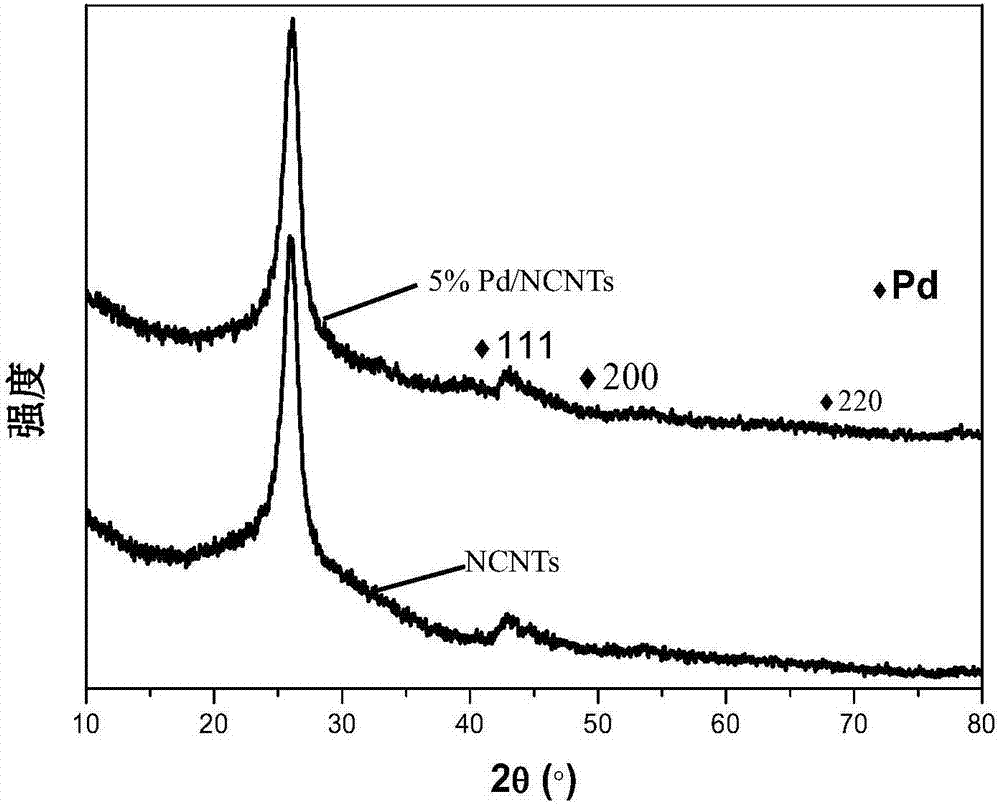

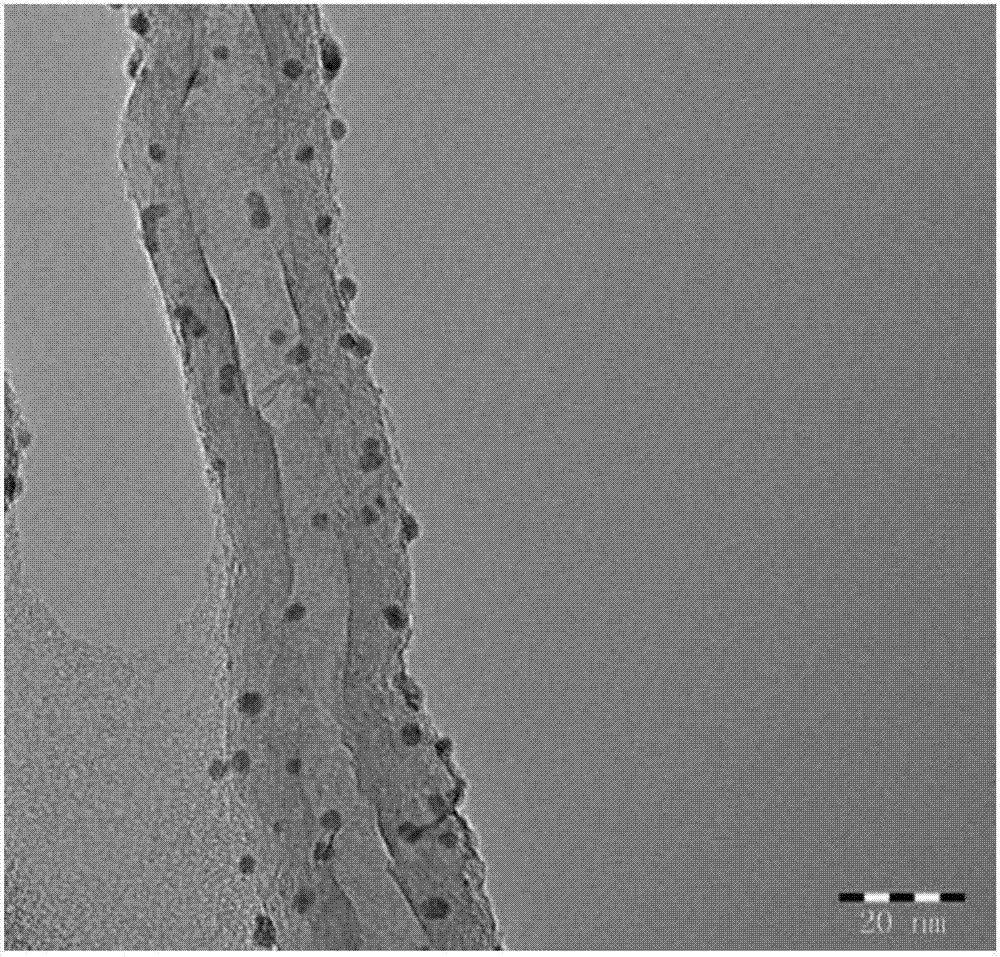

[0035] The catalyst used in embodiment 2 is to directly prepare nitrogen-doped carbon nanotubes by chemical vapor deposition and then prepare the catalyst. The specific preparation process is as follows: with 100mg FeMo / Al 2 o 3 As catalyst, 7.5ml xylene as carbon source, NH 3 (500ml / h) was used as nitrogen source, and nitrogen-doped carbon nanotubes were grown under the condition of raising the temperature to 800° C., reacted for 5 hours, and cooled to room temperature to obtain the product. Then the product was washed with concentrated hydrochloric acid (concentration: 35wt%) for 12 hours, filtered, dried and ground to obtain nitrogen-doped carbon nanotubes. Its specific surface area is 99m 2 / g, the X-ray photoelectron spectroscopy measurement shows that the nitrogen content is 4.21at%. Then ultrasonically disperse 200mg of nitrogen-doped carbon nanotubes in 20ml of deionized water, then add 2.76ml of 6.08mg / ml palladium chloride solution, adjust the pH value to 8.5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com