Quick leaching method of silicate lead oxide concentrates

A technology of silicate and lead oxide, which is applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of low vulcanization efficiency, serious environmental pollution, large amount of waste residue, etc., and achieves mild reaction conditions, simple process flow, The effect of strong responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

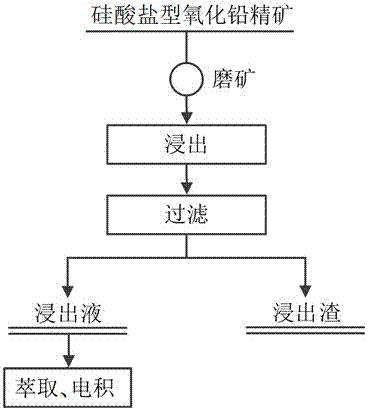

[0021] Example 1: as figure 1 As shown, a kind of rapid leaching method of silicate type lead oxide concentrate, the specific steps are as follows:

[0022] (1) The silicate type lead oxide concentrate is ground until 91.0% of the silicate gangue minerals are dissociated to obtain silicate type lead oxide concentrate powder; in which, in terms of mass percentage, the silicate type lead oxide concentrate is The lead concentrate contains 22.2% lead, a small amount of calcium oxide and magnesium oxide, the oxidation rate of lead is 97%, and the total amount of calcium oxide and magnesium oxide is 2.9%; the main gangue present in the silicate type lead oxide concentrate The minerals are quartz and silicate;

[0023] (2) at a temperature of 45°C, adding the silicate type lead oxide concentrate powder obtained in step (1) into a leaching agent for leaching for 30 minutes to obtain a leaching solution and a leaching residue, wherein the leaching agent is an aqueous solution of metha...

Embodiment 2

[0026] Example 2: as figure 1 As shown, a kind of rapid leaching method of silicate type lead oxide concentrate, the specific steps are as follows:

[0027] (1) The silicate-type lead oxide concentrate is ground until 89.0% of the silicate gangue minerals are dissociated to obtain silicate-type lead oxide concentrate powder; in which, in terms of mass percentage, the silicate-type lead oxide concentrate is The lead concentrate contains 35.4% lead, a small amount of calcium oxide and magnesium oxide, the oxidation rate of lead is 98%, and the total amount of calcium oxide and magnesium oxide is 1.8%; the main gangue existing in the silicate type lead oxide concentrate The minerals are quartz and silicate;

[0028] (2) adding the silicate-type lead oxide concentrate powder obtained in step (1) to a leaching agent for 25 minutes at a temperature of 50° C. to obtain a leaching solution and a leaching residue, wherein the leaching agent is an aqueous solution of methanesulfonic ac...

Embodiment 3

[0031] Example 3: as figure 1 As shown, a kind of rapid leaching method of silicate type lead oxide concentrate, the specific steps are as follows:

[0032] (1) The silicate-type lead oxide concentrate is ground until 88.0% of the silicate gangue minerals are dissociated to obtain silicate-type lead oxide concentrate powder; in which, in terms of mass percentage, the silicate-type lead oxide concentrate is The lead concentrate contains 42.1% lead, a small amount of calcium oxide and magnesium oxide, the oxidation rate of lead is 96.5%, and the total amount of calcium oxide and magnesium oxide is 2.2%; the main gangue existing in the silicate type lead oxide concentrate The minerals are quartz and silicate;

[0033] (2) at a temperature of 55°C, adding the silicate type lead oxide concentrate powder obtained in step (1) into a leaching agent for leaching for 20 minutes to obtain a leaching solution and a leaching residue, wherein the leaching agent is an aqueous solution of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com