Fe-M/CNTs denitration catalyst, preparation method and application of catalyst in ammonia selective catalytic reduction to nitrogen oxide

A denitrification catalyst, fe-m technology, applied in the field of environmental catalytic purification, can solve the problems of high catalyst preparation cost, large amount of raw materials used, no economic benefits, etc., and achieve excellent denitrification performance, low cost, and good industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Acid treatment of carbon nanotube materials: 3g CNTs were added to 150mL concentrated acid solution, in which the volume ratio of concentrated nitric acid to concentrated sulfuric acid was 1:1, after ultrasonic dispersion for 60min, condensed and refluxed in an oil bath at 110°C for 5h, and deionized water Dilute and cool, and when the pH of the washing mixture is 6-7, filter it with suction, dry it in an oven at 80°C, and grind it for later use.

Embodiment 2

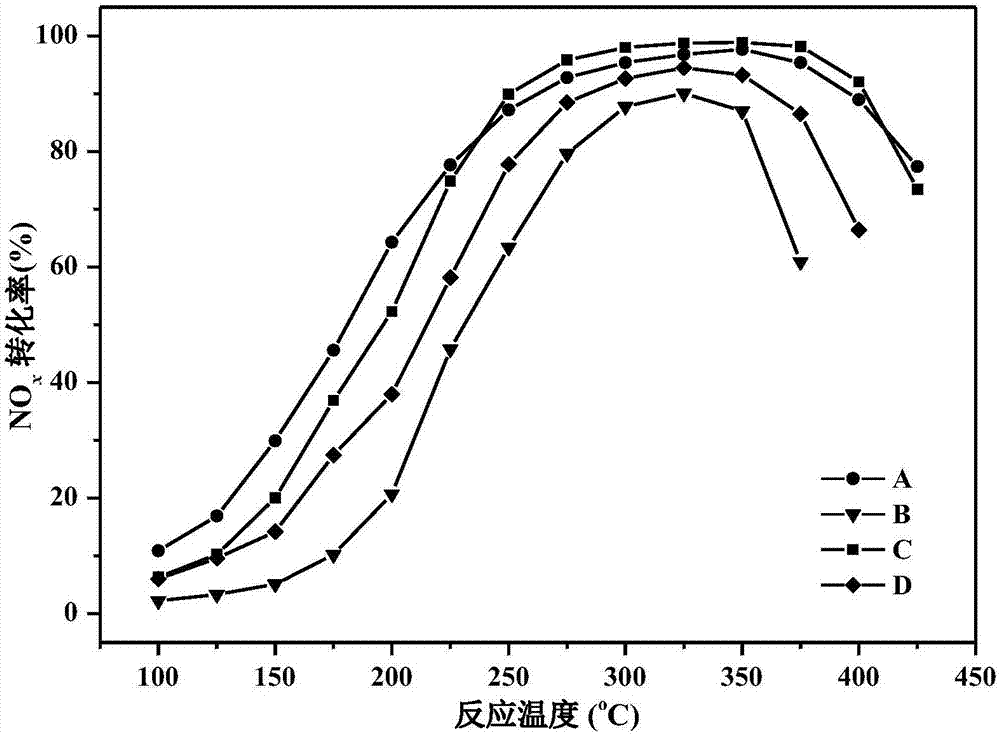

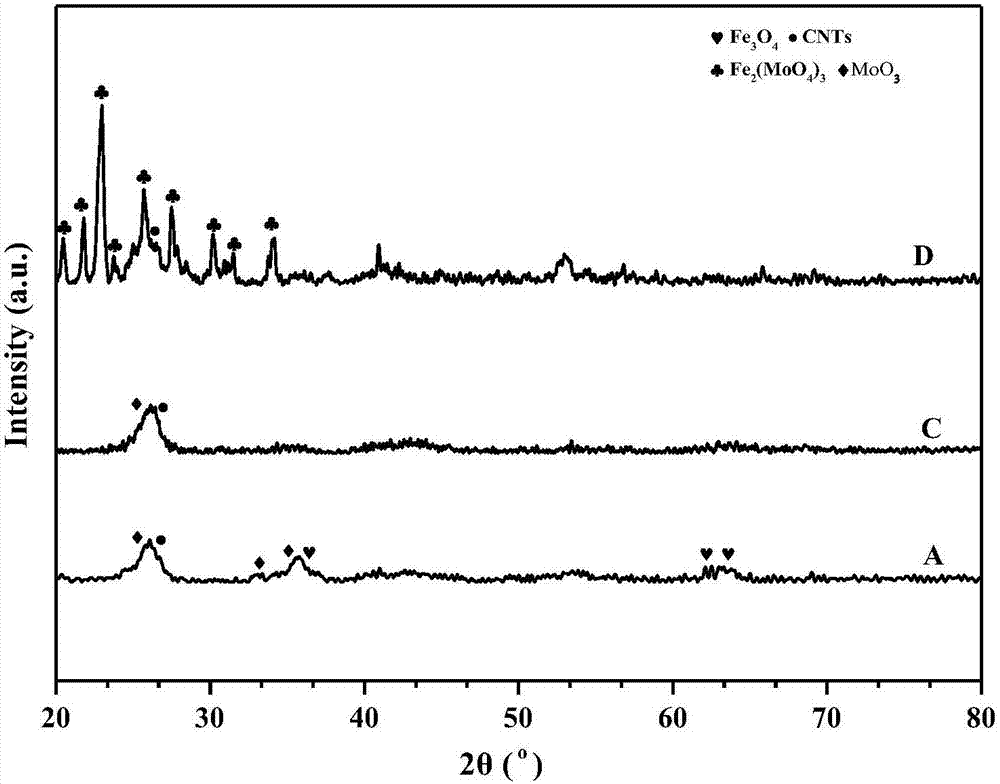

[0021] Take by weighing the CNTs obtained in 0.6g embodiment 1 and use a small amount of H 2 O infiltration; weigh 2.4g ferric nitrate, 0.1g ammonium heptamolybdate, 0.1g citric acid dissolved in 10mL H 2 After the solution is mixed evenly in O, the solution is evenly impregnated onto the wet CNTs surface, stirred in a water bath at 40°C until the water evaporates, dried in an oven at 80°C for 12 hours, and finally the dried sample was placed in a muffle furnace at 400°C The carbon nanotube-supported iron and molybdenum two-component catalyst A was prepared by calcining at lower temperature for 3 hours. With other conditions unchanged, 0.1 g of oxalic acid was used instead of citric acid to prepare carbon nanotube-supported iron and molybdenum two-component catalyst B.

Embodiment 3

[0023] According to the A catalyst method of the present invention of embodiment 2, adopt 0.2g ammonium heptamolybdate to replace 0.1g ammonium heptamolybdate, prepare carbon nanotube supported iron and molybdenum two-component catalyst C; Adopt 0.6g ammonium heptamolybdate to replace 0.1 g of ammonium heptamolybdate to obtain a carbon nanotube-supported iron and molybdenum two-component catalyst D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com