Method of subjecting Haematococcus pluvialis to attachment culture with rotary biomembrane reactor to produce astaxanthin

A technology of Haematococcus pluvialis and membrane reactor, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effect of simple biomass harvesting, small footprint, and increased algae biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Effect of Nitrogen Deficiency Stress on Astaxanthin Accumulation at Different Times in Batch Culture Mode in Example 1

[0022] 1) Preparation of seed liquid: Inoculate Haematococcus pluvialis species into BG11 culture solution (sodium nitrate 1500mg / L, dipotassium hydrogen phosphate 40mg / L, magnesium sulfate heptahydrate 75mg / L, calcium chloride dihydrate 36mg / L L, citric acid 6mg / L, ferric ammonium citrate 6mg / L, disodium edetate 1mg / L, sodium carbonate 20mg / L, boric acid 2.86mg / L, manganese chloride tetrahydrate 1.86mg / L, seven Zinc sulfate water 0.22mg / L, sodium molybdate dihydrate 0.39mg / L, copper sulfate pentahydrate 0.08mg / L, cobalt nitrate hexahydrate 0.05mg / L) in the triangular flask, under light intensity 1000-4000lx, room temperature ( 20-30°C, the same below), cultivate for 5-7 days, and obtain a higher density algae liquid as the seed liquid;

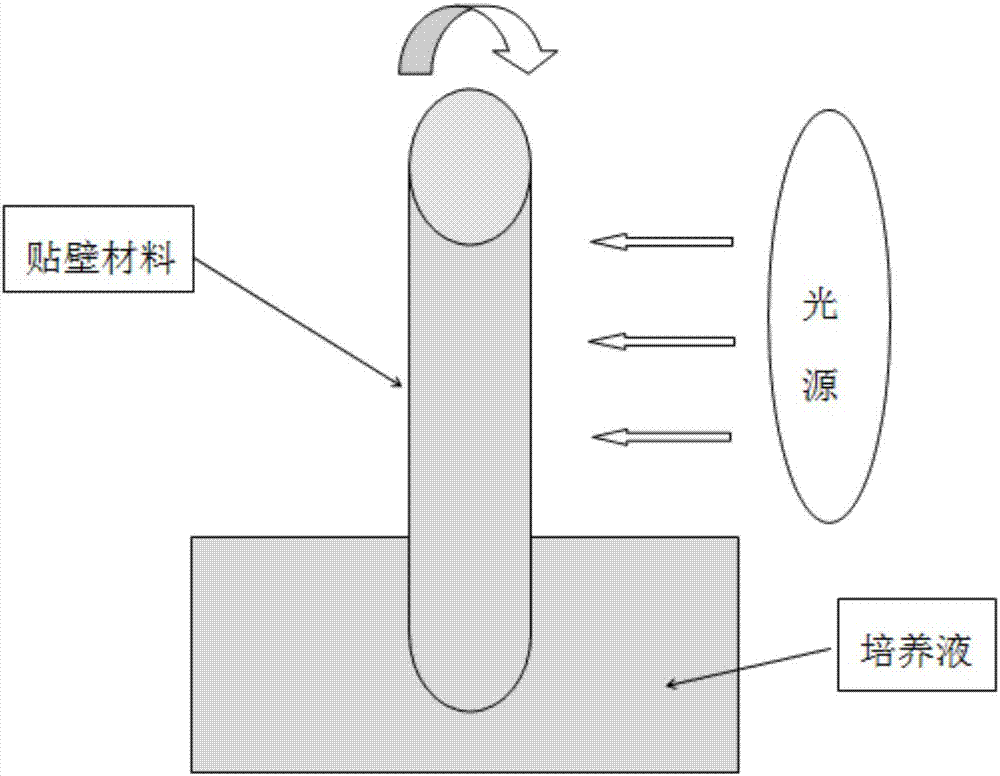

[0023] 2) Adhesive culture: take the seed liquid in step 1), transfer it to a rotating biofilm reactor containing...

Embodiment 2

[0028] The impact of different light intensity stress on the accumulation of astaxanthin under the batch culture mode of embodiment 2

[0029] 1) Preparation of seed liquid: Inoculate Haematococcus pluvialis species into BG11 culture solution (sodium nitrate 1500mg / L, dipotassium hydrogen phosphate 40mg / L, magnesium sulfate heptahydrate 75mg / L, calcium chloride dihydrate 36mg / L L, citric acid 6mg / L, ferric ammonium citrate 6mg / L, disodium edetate 1mg / L, sodium carbonate 20mg / L, boric acid 2.86mg / L, manganese chloride tetrahydrate 1.86mg / L, seven Zinc sulfate water 0.22mg / L, sodium molybdate dihydrate 0.39mg / L, copper sulfate pentahydrate 0.08mg / L, cobalt nitrate hexahydrate 0.05mg / L) in a conical flask, under light intensity 1000-4000lx, room temperature , cultured for 5-7d, to obtain higher density algae liquid as seed liquid;

[0030] 2) Adhesive culture: take the seed liquid in step 1), transfer it to a rotating biofilm reactor containing BG11 culture liquid, and carry out...

Embodiment 3

[0035] Example 3 Simultaneously performing nitrogen deficiency stress and high light intensity stress on Haematococcus pluvialis in batch culture mode to induce astaxanthin accumulation

[0036] 1) Preparation of seed liquid: Inoculate Haematococcus pluvialis species into BG11 culture solution (sodium nitrate 1500mg / L, dipotassium hydrogen phosphate 40mg / L, magnesium sulfate heptahydrate 75mg / L, calcium chloride dihydrate 36mg / L L, citric acid 6mg / L, ferric ammonium citrate 6mg / L, disodium edetate 1mg / L, sodium carbonate 20mg / L, boric acid 2.86mg / L, manganese chloride tetrahydrate 1.86mg / L, seven Zinc sulfate water 0.22mg / L, sodium molybdate dihydrate 0.39mg / L, copper sulfate pentahydrate 0.08mg / L, cobalt nitrate hexahydrate 0.05mg / L) in a conical flask, under light intensity 1000-4000lx, room temperature , cultured for 5-7d, to obtain higher density algae liquid as seed liquid;

[0037] 2) Adhesive culture: take the seed liquid in step 1), transfer it to a rotating biofilm r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com