Mixed additive for electrolyzing acid etching waste liquid and method of preparing copper powder by using mixed additive

A technology of acidic etching waste liquid and mixed additives, which is applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of insufficient copper powder purity and copper recovery rate, high production cost, human body and environmental hazards, and reduce recycling The effect of copper extraction cost, stable product quality, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

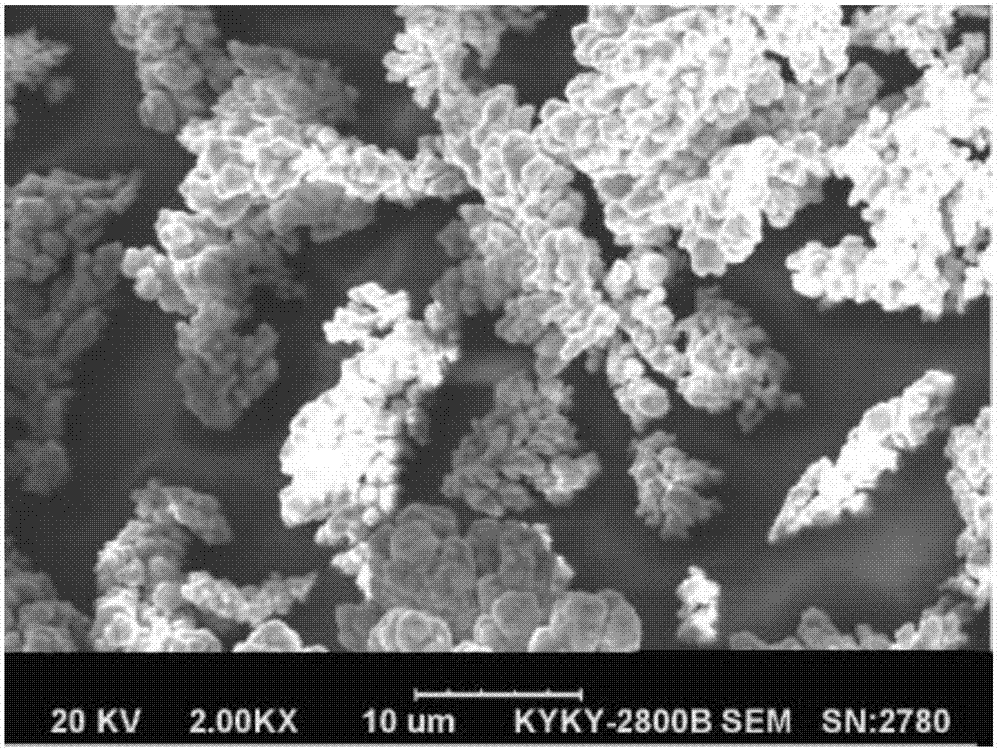

Image

Examples

Embodiment 1

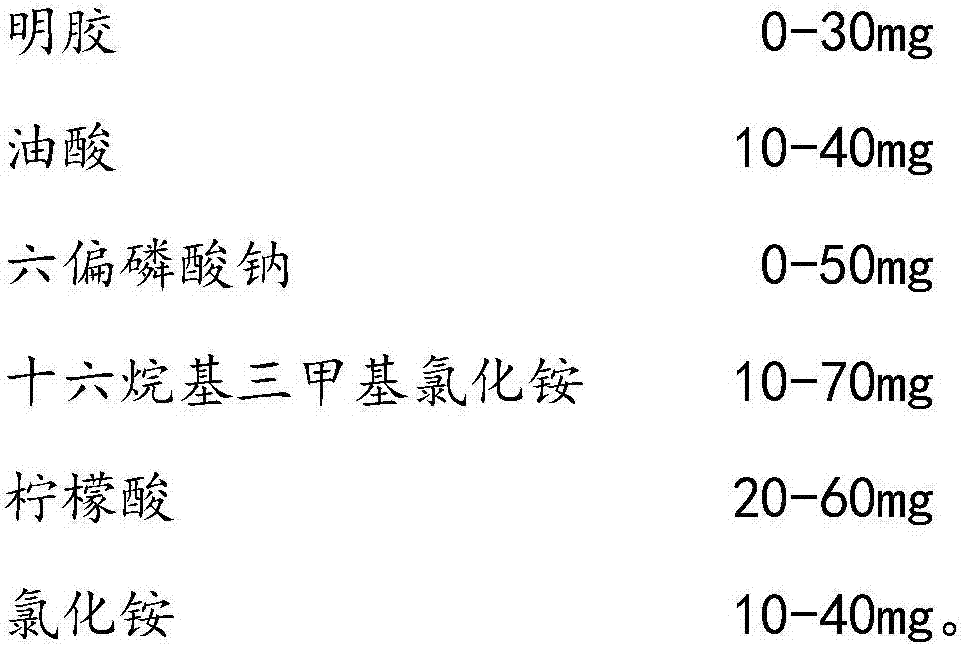

[0034] The mixed additive used for preparing copper powder from electrolytic acidic etching waste liquid contains the following components in the aqueous solution of every liter of mixed additive:

[0035]

[0036]

[0037] The method for preparing copper powder by using the above-mentioned mixed additive electrolysis acidic etching waste solution comprises the following steps:

[0038] 1) Microporous precision filtration is carried out to the etching waste liquid, and the copper ion concentration of the obtained solution is 120g / L;

[0039] 2) Dilute the filtered etching waste liquid, add water until the copper ion concentration is 30g / L, add 20ml / L of mixed additives, and make an electrolyte;

[0040] 3) The electrolyte is pumped into the electrolytic cell, and the titanium-based manganese dioxide electrode is used as the anode, and the stainless steel plate electrode is used as the cathode for direct electrolytic treatment. The temperature of the electrolyte is 20±2°C...

Embodiment 2

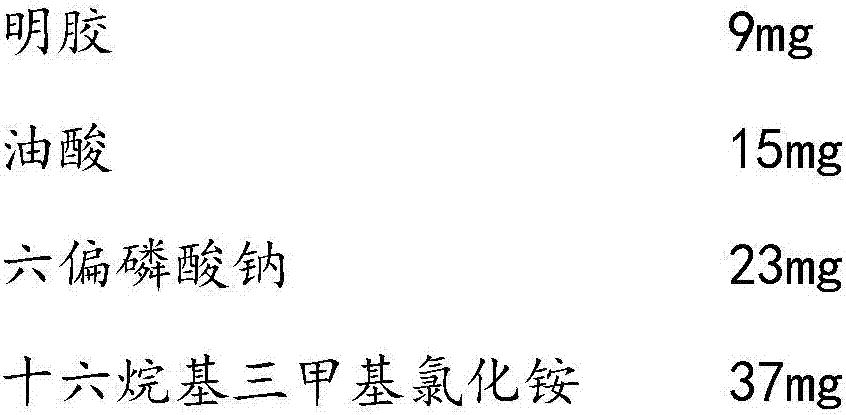

[0044] The mixed additive used for preparing copper powder from electrolytic acidic etching waste liquid contains the following components in the aqueous solution of every liter of mixed additive:

[0045]

[0046] The method for preparing copper powder by electrolyzing acidic etching waste liquid with above-mentioned mixed additives, the operation steps are:

[0047] 1) Microporous precision filtration is carried out to the etching waste liquid, and the copper ion concentration of the obtained solution is 150g / L;

[0048] 2) Dilute the filtered etching waste liquid, add water until the copper ion concentration is 50g / L, add 63ml / L of mixed additives, and make an electrolyte;

[0049] 3) Pump the electrolyte into the electrolytic cell, use the titanium-based iridium-tantalum coating electrode as the anode, and the stainless steel plate electrode as the cathode for direct electrolytic treatment. The temperature of the electrolyte is 30±2°C, and the current density is 1300A / m...

Embodiment 3

[0053]The mixed additive used for preparing copper powder from electrolytic acidic etching waste liquid contains the following components in the aqueous solution of every liter of mixed additive:

[0054]

[0055] The method for preparing copper powder by electrolyzing acidic etching waste liquid with above-mentioned mixed additives, the operation steps are:

[0056] 1) Microporous precision filtration is carried out to the etching waste liquid, and the copper ion concentration of the obtained solution is 180g / L;

[0057] 2) Dilute the filtered etching waste liquid, add water until the copper ion concentration is 45g / L, add 30ml / L of mixed additives, and make an electrolyte;

[0058] 3) The electrolyte is pumped into the electrolytic cell, and the titanium-based iridium-ruthenium coated electrode is used as the anode, and the stainless steel plate electrode is used as the cathode for direct electrolytic treatment. The temperature of the electrolyte is 43±2°C, and the curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com