Sweet potato plantation method

A planting method and sweet potato technology, applied in botany equipment and methods, soil preparation methods, fertilization methods, etc., can solve the problems of affecting the yield of sweet potatoes, low fertilizer utilization rate, unstable sweet potato planting volume, etc., and achieve enhanced water and fertilizer retention capacity , improved disease prevention ability, and obvious effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Make base fertilizer

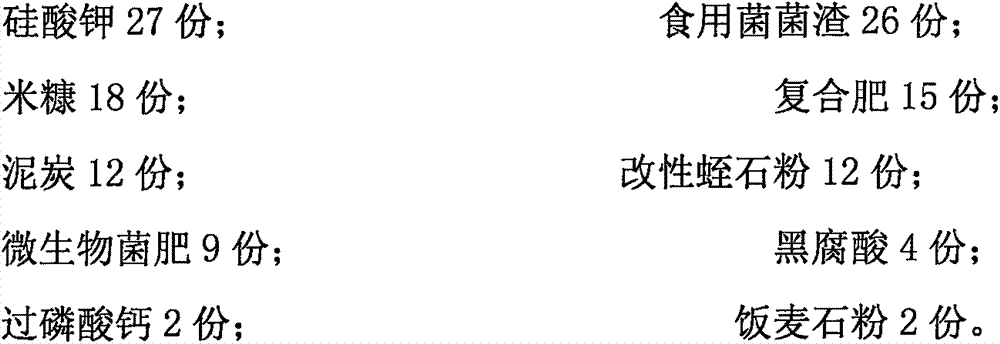

[0035] 1. In parts by weight, take the following raw material components:

[0036]

[0037]

[0038] Wherein, the modified vermiculite powder is made by mixing the raw materials of the following parts by weight:

[0039] 12 parts of pig manure degradation liquid modified sodium-based vermiculite powder; 12 parts of hydroxyl iron coated vermiculite powder;

[0040] 10 parts of hydroxyl iron modified sodium vermiculite powder; 8 parts of tannic acid modified vermiculite powder.

[0041] Described microbial bacterial fertilizer is made by mixing the raw materials of following weight parts:

[0042] 8 parts of autogenous nitrogen-fixing bacteria; 6 parts of branch mycorrhizal fungi;

[0043] 5 parts of rhizobia; 4 parts of ectomycorrhizal fungi;

[0044] 3 parts of Bacillus coliformis.

[0045] The potassium silicate is prepared by composting sheep manure, chicken manure, duck manure and straw in a weight ratio of 8:3:3:2 for 30 days.

...

Embodiment 2

[0067] 1. Make base fertilizer

[0068] 1. In parts by weight, take the following raw material components:

[0069]

[0070] Wherein, the modified vermiculite powder is made by mixing the raw materials of the following parts by weight:

[0071] 17 parts of pig manure degradation solution modified sodium-based vermiculite powder; 17 parts of hydroxyl iron coated vermiculite powder;

[0072] 14 parts of hydroxyl iron modified sodium vermiculite powder; 13 parts of tannic acid modified vermiculite powder.

[0073] Described microbial bacterial fertilizer is made by mixing the raw materials of following weight parts:

[0074] 10 parts of autogenous nitrogen-fixing bacteria; 9 parts of branch mycorrhizal fungi;

[0075] 7 parts of rhizobia; 6 parts of ectomycorrhizal fungi;

[0076] 5 parts of Bacillus coliformis.

[0077] The potassium silicate is prepared by composting sheep manure, chicken manure, duck manure and straw in a weight ratio of 8:3:3:2 for 35 days.

[0078] ...

Embodiment 3

[0099] 1. Make base fertilizer

[0100] 1. In parts by weight, take the following raw material components:

[0101]

[0102] Wherein, the modified vermiculite powder is made by mixing the raw materials of the following parts by weight:

[0103]23 parts of pig manure degradation solution modified sodium-based vermiculite powder; 22 parts of hydroxyl iron coated vermiculite powder;

[0104] 18 parts of hydroxyl iron modified sodium vermiculite powder; 17 parts of tannic acid modified vermiculite powder.

[0105] The potassium silicate is made by composting sheep manure, chicken manure, duck manure and straw in a weight ratio of 8:3:3:2 for 40 days.

[0106] Described microbial bacterial fertilizer is made by mixing the raw materials of following weight parts:

[0107] 12 parts of autogenous nitrogen-fixing bacteria; 12 parts of branch mycorrhizal fungi;

[0108] 10 parts of rhizobia; 8 parts of ectomycorrhizal fungi;

[0109] Glial bacillus 8 parts.

[0110] 2. Prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com