Method for synthesizing high specific surface mesoporous silicon carbide at low temperature and silicon carbide product

A technology of mesoporous silicon carbide and high specific surface, applied in the field of silicon carbide products, low temperature synthesis of high specific surface mesoporous silicon carbide, can solve the problems of low product purity, small specific surface area of silicon carbide materials, pollution, etc., and achieve particle size And the particle distribution is uniform, no secondary pollution, and the effect of simplifying the pickling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

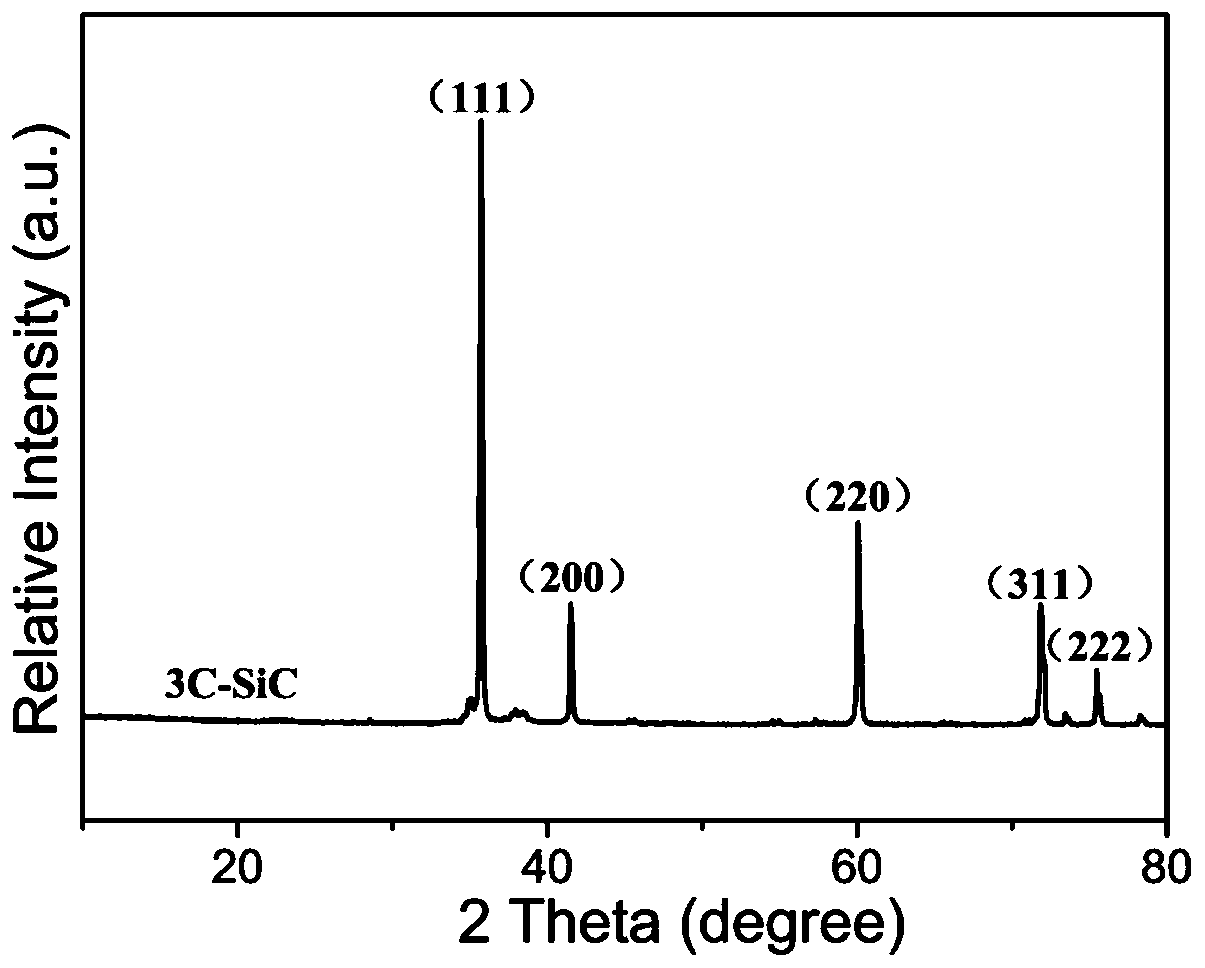

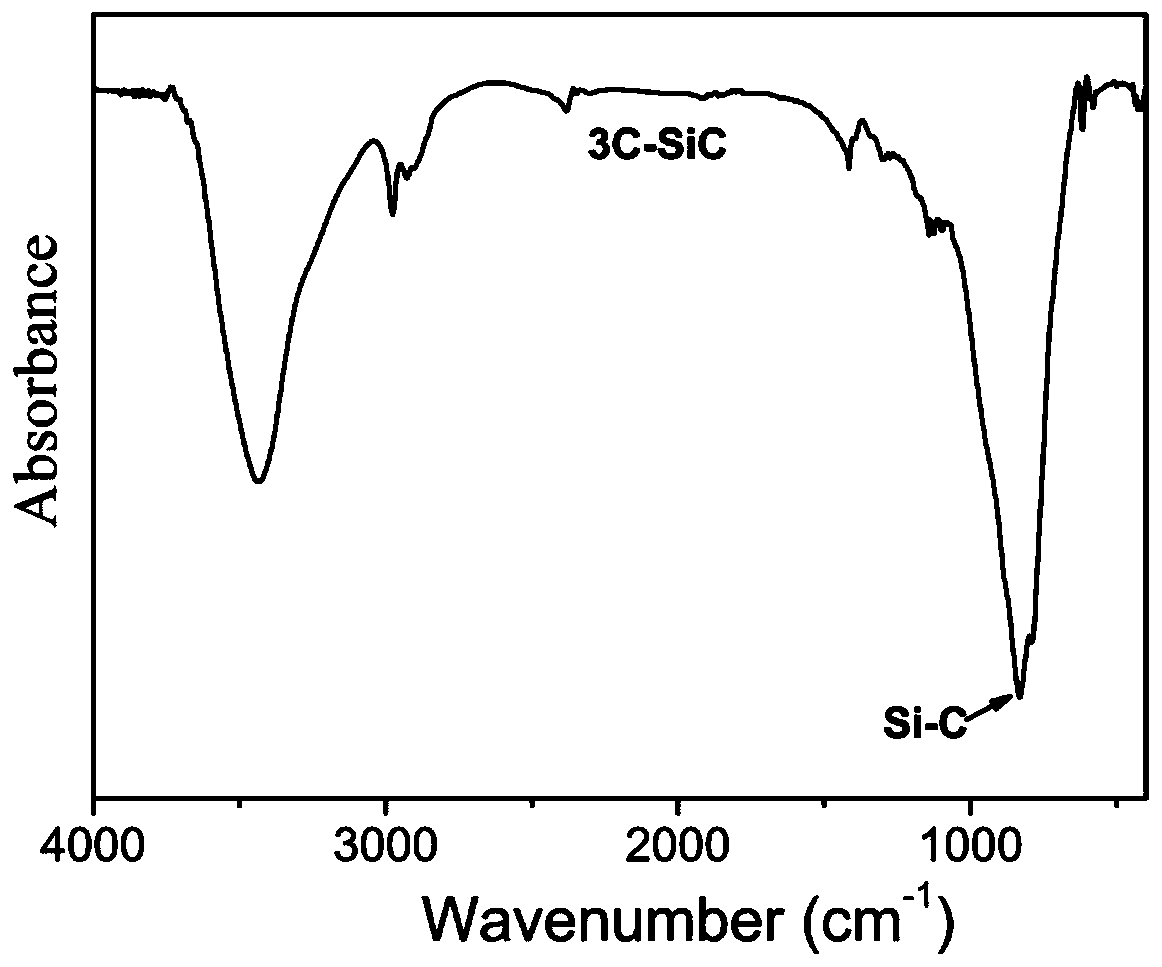

Embodiment 1

[0035] Add 5g of deionized water, 3g of ethanol, and 0.5g of HCl solution (1mol / L) into a 100mL polyethylene bottle with a seal and mix well, then add 4.1g of tri-block polymer P123 under stirring conditions for 2 hours until completely dissolved . Then 10 g of TEOS and 5 g of furfuryl alcohol were slowly added into the above mixed solution under vigorous stirring, aged at room temperature for 2 days, and then vacuum-dried at 70° C. for 2 days. The resulting block was taken out and carbonized for 6 hours under the protection of argon to obtain a composite filled with carbon in mesoporous silica. After grinding the above compound, add magnesium powder and mix at a mass ratio of 1:1, and react at 700°C for 6 hours. The resulting product is cleaned in 1mol / L hydrochloric acid solution, and there is no excess SiO in the product 2 There is no need to use strong corrosive liquids such as hydrofluoric acid. Then wash with deionized aqueous solution, after filtering and drying, the...

Embodiment 2

[0041] Add 5g of deionized water, 3g of ethanol, and 0.5g of HCl solution (1mol / L) into a 100mL polyethylene bottle with a seal and mix well, then add 4.1g of tri-block polymer P123 under stirring conditions for 2 hours until completely dissolved . Then 10 g of TEOS and 5 g of furfuryl alcohol were slowly added into the above mixed solution under vigorous stirring, aged at room temperature for 2 days, and then vacuum-dried at 70° C. for 2 days. The resulting block was taken out and carbonized for 6 hours under the protection of argon to obtain a composite filled with carbon in mesoporous silica. After grinding the above compound, add magnesium powder and mix at a mass ratio of 1:2, and react at 700°C for 6 hours. The resulting product is cleaned in 1mol / L hydrochloric acid solution, and there is no excess SiO in the product 2 Therefore, there is no need to use strong corrosive liquids such as hydrofluoric acid, then deionized water solution, liquid cleaning, after filtration...

Embodiment 3

[0043] Add 5g of deionized water, 5g of ethanol, and 1.0g of HCl solution (1mol / L) into a 100mL sealed polyethylene bottle and mix well, then add 3g of triblock polymer P123 under stirring conditions for 2 hours until completely dissolved. Then, 12 g of TEOS and 5 g of furfuryl alcohol were slowly added into the above mixed solution under vigorous stirring, aged at room temperature for 2 days, and then vacuum-dried at 70° C. for 2 days. The resulting block was taken out and carbonized for 6 hours under the protection of argon to obtain a composite filled with carbon in mesoporous silica. After grinding the above compound, add magnesium powder and mix at a mass ratio of 1:3, and react at 650°C for 6 hours. The resulting product is in 2mol / L hydrochloric acid solution, and there is no excess SiO in the product 2 Therefore, there is no need to use strong corrosive liquids such as hydrofluoric acid, and then a deionized aqueous solution is filtered and dried to obtain a mesoporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com