A kind of industrial preparation method of zirconium-loaded nanocomposite resin adsorbent

A nano-composite, resin adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as heat transfer and flow, achieve less material flow, save zirconium salt raw materials, save processes and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

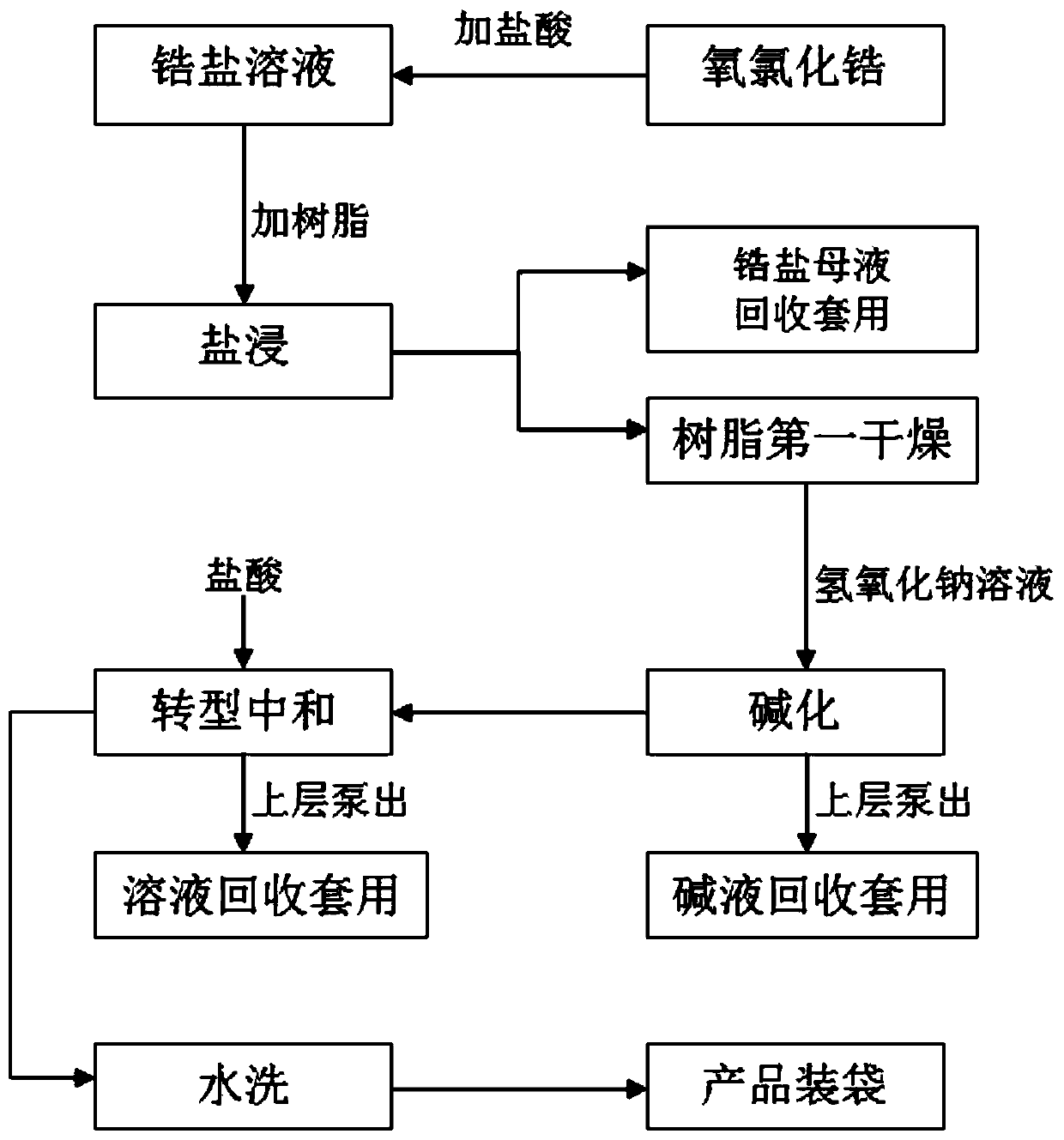

Method used

Image

Examples

Embodiment 1

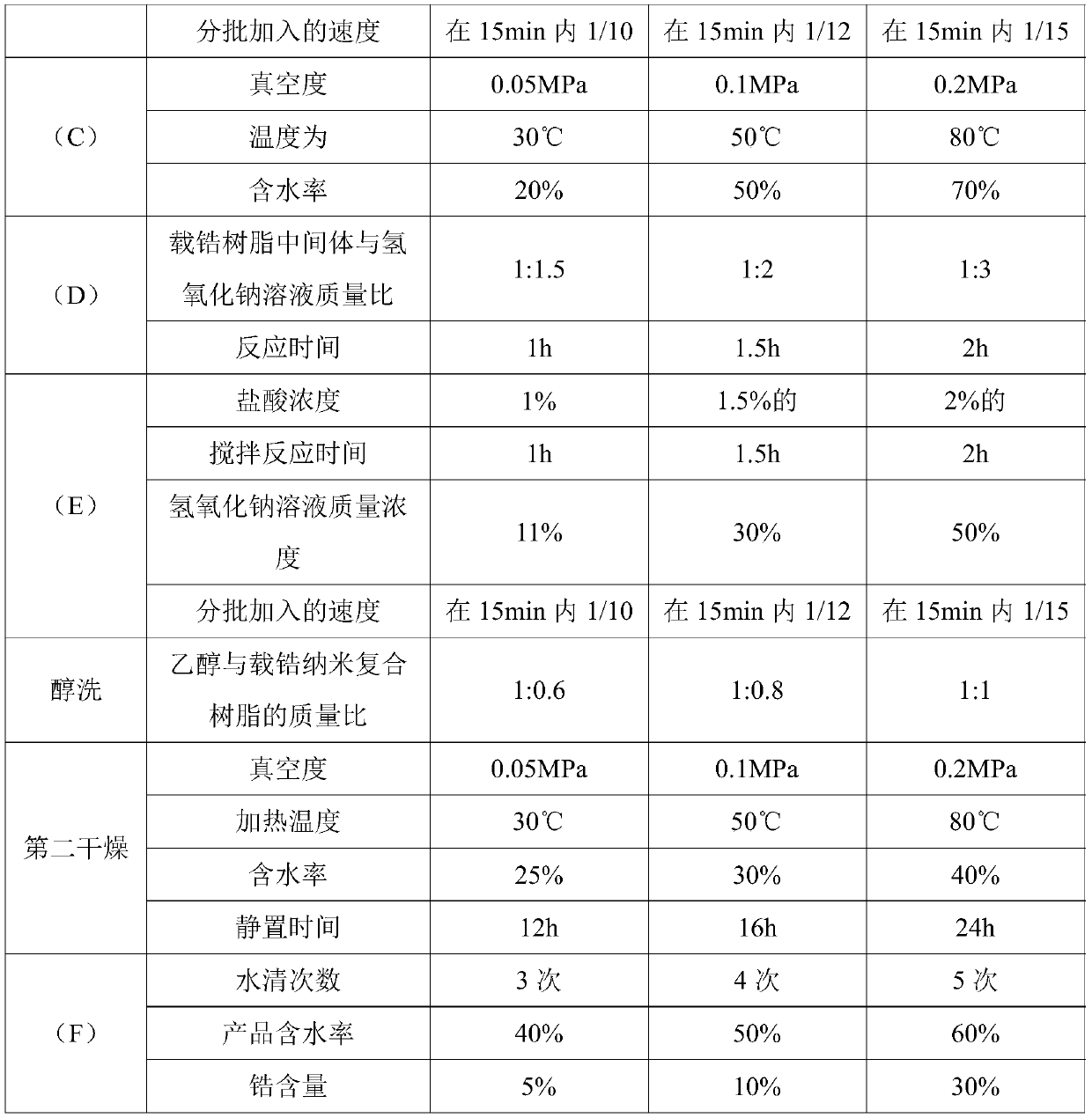

[0042] An industrial preparation method of a zirconium-loaded nanocomposite resin adsorbent, comprising the following specific steps:

[0043] (1) Cleaning and drying of raw materials

[0044] First, add the commercially available NDA900 type resin raw material into the filter car, add 2t of resin in each batch, add about 2t of methanol solution, stir intermittently at 20-45°C, let it stand for 1h, and filter out the methanol solution by gravity filtration. The methanol solution that goes out is returned to the distillation system and reused after distillation;

[0045] Then transfer the resin to a vacuum desiccator and heat it to 30-60°C with a water bath while maintaining a vacuum of 0.05-0.2MPa. When the water content drops to 15-30%, unload to obtain a washed NDA900 resin.

[0046] (2) Zirconium salt impregnation and drying

[0047] Add 1-2t zirconium oxychloride (commercially available) and 20% hydrochloric acid into a 6000L reactor to prepare a 3000L zirconium salt sol...

Embodiment 2

[0060] The physical and chemical index of embodiment 2 loaded zirconium nanocomposite resin adsorbent products and the test method of application performance

[0061] 1. Appearance

[0062] By visual inspection, the appearance of the product of the present invention is moist light yellow spherical particles without visible mechanical impurities with normal eyesight.

[0063] 2. Physical and chemical indicators

[0064] 2.1 Sample pretreatment: Wash the sample repeatedly with deionized water until the effluent is clear and transparent, and the pH is neutral.

[0065] 2.2 Nanoparticles are processed according to the method specified in JY / T 011-1996:

[0066] Nanoparticles (calculated as ≤100nm), ≥20%.

[0067] 2.3 The mass fraction of zirconium content is pretreated according to the microwave digestion method specified in HJ / T0166-2004, and then the sample is measured according to the method specified in GB / T15072.18-2008:

[0068] The mass fraction of zirconium content is ...

Embodiment 3

[0083] An industrial preparation method of a zirconium-loaded nanocomposite resin adsorbent, comprising the following steps:

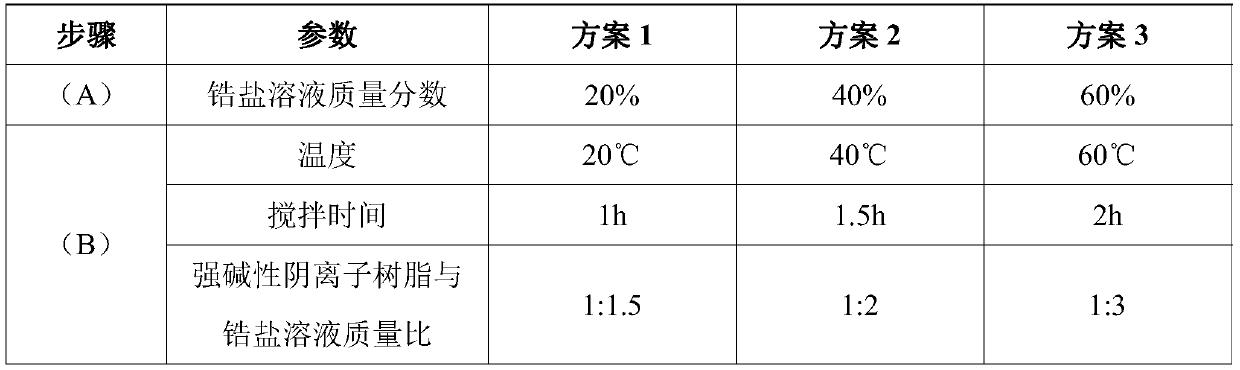

[0084] (A) Preparation of zirconium salt solution: the zirconium salt is dissolved in an acidic aqueous solution to obtain a zirconium salt solution with a mass fraction of 20%-60%; the zirconium cation present in the acidic aqueous solution is obtained, and the zirconium salt is selected from oxychloride zirconium oxide or zirconium carbonate, and the acidic aqueous solution is selected from 20-30% hydrochloric acid, 20-50% sulfuric acid or 20-30% nitric acid.

[0085] Select the zirconium salt solution of this mass fraction range in industrial mass production, when the concentration of zirconium salt solution is lower than 20%, be unfavorable for reaction to carry out, cause the zirconium loading rate on the finished resin (referring to strongly basic anion resin) to be low, As a result, the yield of the zirconium-loaded nanocomposite resin adsorbent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com