Enzyme@ZIF-8@Fe3O4 magnetic nanoenzyme reactor and preparation method thereof

A magnetic nanometer, enzyme reactor technology, applied in chemical instruments and methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve the problem of increasing reaction costs, difficulty in recycling, and reaction speed. It can reduce the problems such as decrease, and achieve the effects of good reusability, simple preparation method, and improved thermal stability and acid-base stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Citric acid modified Fe 3 o 4 magnetic nanoparticles

[0039] 1.0g (4mmol) magnetic Fe 3 o 4 Add the powder and 50mL ultrapure water into a 250mL three-neck flask, and ultrasonicate for 20 minutes under stirring to make the magnetic Fe 3 o 4 The powder is uniformly dispersed in ultrapure water, and then 4.5mL of 2.0mol / L citric acid aqueous solution is added, and the 2 Stir at 90°C for 90 minutes under protection, cool to room temperature, separate the product with a magnet, wash the product with pure water and dry it in a vacuum oven at 60°C for 5 hours to obtain citric acid-modified Fe 3 o 4 Magnetic nanoparticles (CA-Fe 3 o 4 ).

[0040] 2. Preparation of HRP@ZIF-8@Fe 3 o 4 Magnetic Nanozyme Reactor

[0041] 50.0mg citric acid modified Fe 3 o 4 After the magnetic nanoparticles are ground, place them in a 100mL beaker, add 10mL of 50% ethanol aqueous solution, and then add 55.0mg (0.29mmol) Zn(NO 3 ) 2 and 3mg mass fraction of 37% (0.029mmol) HCl aq...

Embodiment 2

[0043] In this example, the horseradish peroxidase in Example 1 was replaced with an equal mass of chloroperoxidase (CPO), and the other steps were the same as in Example 1 to obtain CPO@ZIF-8@Fe 3 o 4 Magnetic Nanozyme Reactor.

Embodiment 3

[0045] In this example, the horseradish peroxidase in Example 1 was replaced with an equal mass of cytochrome C (Cyt C), and the other steps were the same as in Example 1 to obtain Cyt C@ZIF-8@Fe 3 o 4 Magnetic Nanozyme Reactor.

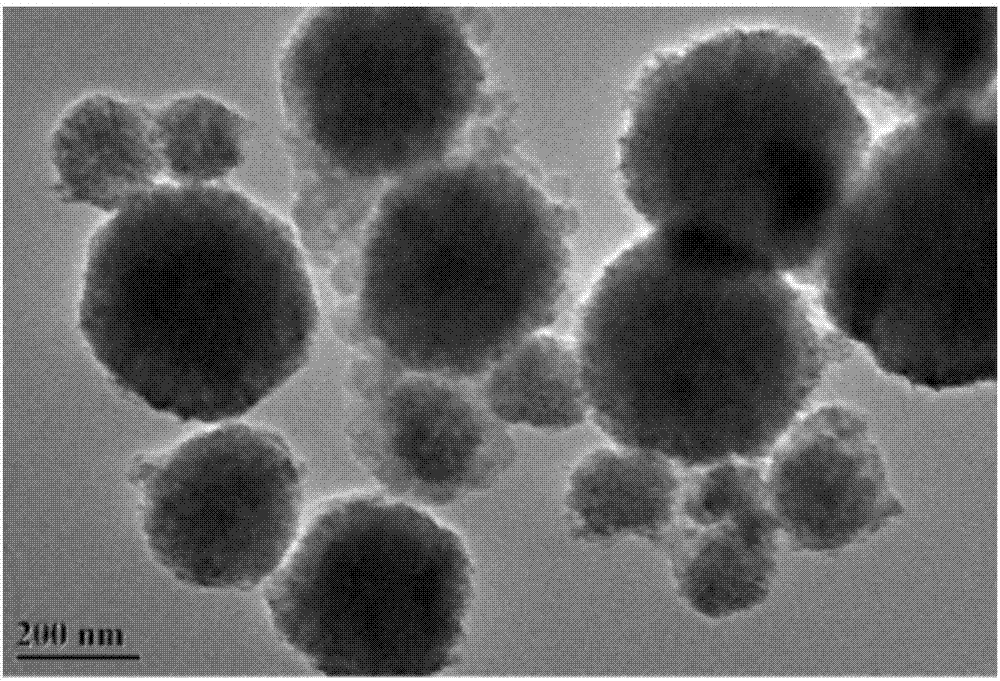

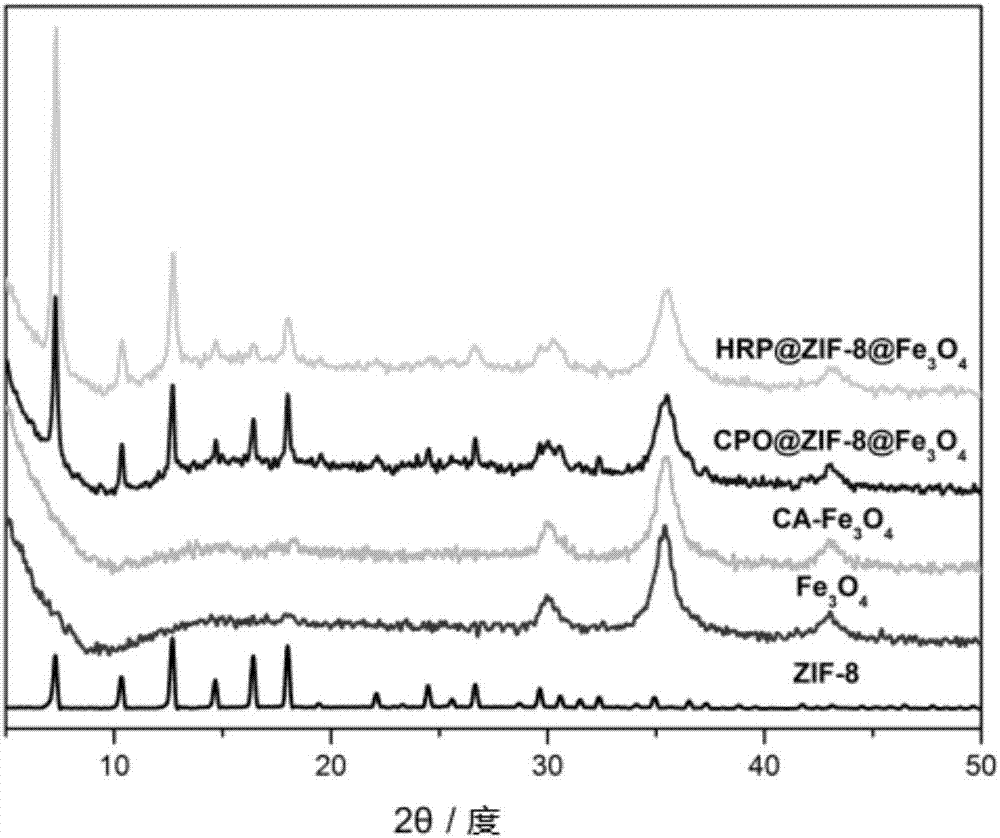

[0046] The inventor adopts environmental scanning electron microscope-EDS energy spectrum, transmission electron microscope, X-ray diffractometer, Fourier transform infrared spectrometer, thermal analysis system to characterize the magnetic nanozyme reactor obtained in Examples 1~3 respectively, the results are shown in Figure 1-8 . Depend on figure 1 , 2 Visible, citrate-modified magnetic Fe 3 o 4 After coating ZIF-8, the size increased significantly, and the citric acid-modified magnetic Fe 3 o 4 The particle size of ZIF-8 is about 250-300nm, and the shell of ZIF-8 is about 50-80nm. The formed HRP@ZIF-8@Fe 3 o 4 The magnetic nanozyme reactor is spherical with uniform shape. Depend on image 3 Visible, HRP@ZIF-8@Fe 3 o 4 and CPO@ZIF-8@...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com