Mpg-C3N4 adsorbing material as well as preparation method and application thereof

A mesoporous carbon nitride, adsorption material technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve problems such as poor adsorption effect of antibiotics, and achieve simple and easy operation in the adsorption process and material synthesis process. Simple, high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

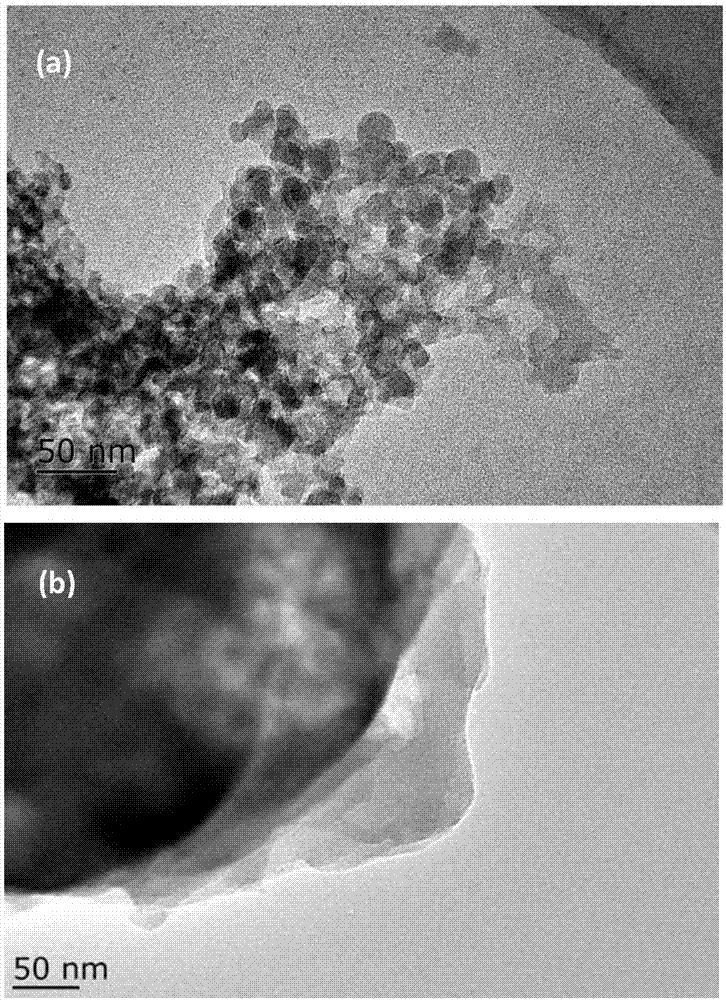

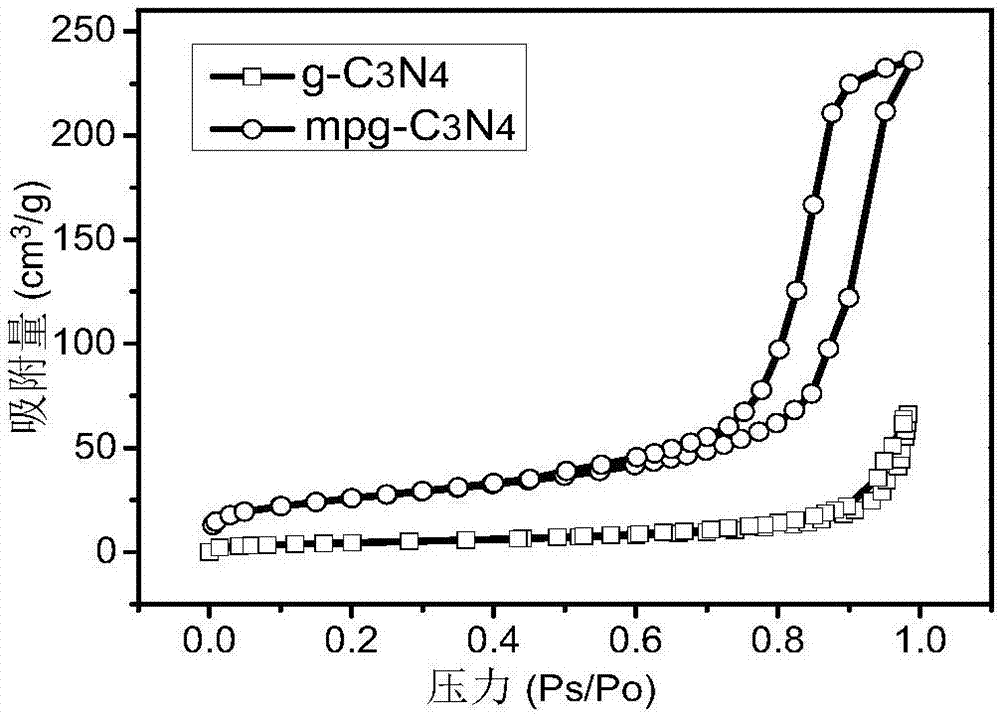

[0032] A preparation method of mesoporous carbon nitride adsorption material, comprising the following steps:

[0033] 1. Take 5mL cyanamide and place it in an alumina crucible, add 3mL silicon dioxide (SiO 2 ) sol, heated in a water bath at 50°C and stirred until completely mixed, and then dried in a vacuum oven at 50°C for 24 hours to obtain block solid A.

[0034] 2. Grind the obtained massive solid A and then transfer it to a muffle furnace to raise the temperature to 550°C at a rate of 3°C / min and keep the temperature for 3h to obtain a light yellow solid B.

[0035] 3. Put the obtained light yellow solid B3g into 50mL of 4mol / L ammonium bifluoride, stir for 72h to remove the silica template. Afterwards, carry out suction filtration and wash with ultrapure water and absolute ethanol, and then place it in a vacuum drying oven at 50°C for 24 hours. After cooling to room temperature, grind and sieve to obtain mpg-C 3 N 4 -1 adsorbent.

Embodiment 2

[0042] A kind of preparation of mesoporous carbon nitride adsorbent comprises the following steps:

[0043] 1. Weigh 5mL of cyanamide into an alumina crucible, add 6mL of silica sol to it, heat in a water bath at 50°C and stir until completely mixed, then dry in a vacuum oven at 50°C for 24h to obtain block solid A .

[0044]2. Grind the obtained massive solid A and then transfer it to a muffle furnace to raise the temperature to 550°C at a rate of 3°C / min and keep the temperature for 3h to obtain a light yellow solid B.

[0045] 3. Put the obtained light yellow solid B3g into 50mL of 4mol / L ammonium bifluoride, stir for 72h to remove the silica template. Afterwards, carry out suction filtration and wash with ultrapure water and absolute ethanol, and then place it in a vacuum drying oven at 50°C for 24 hours. After cooling to room temperature, grind and sieve to obtain mpg-C 3 N 4 -2 Adsorbent.

Embodiment 3

[0047] 1. Weigh 8mL of cyanamide into an alumina crucible, add 6mL of silica sol to it, heat in a water bath at 70°C and stir until completely mixed, then place in a vacuum oven and dry at 70°C for 18 hours to obtain blocky solid A .

[0048] 2. Grind the obtained massive solid A and then transfer it to a muffle furnace to raise the temperature to 450°C at a rate of 2°C / min and keep the temperature for 4h to obtain a light yellow solid B.

[0049] 3. Put 5 g of the obtained pale yellow solid B into 80 mL of 6 mol / L ammonium bifluoride, stir for 48 h to remove the silica template. Then carry out suction filtration and wash with ultrapure water and sewage ethanol, then place it in a vacuum drying oven at 70°C for 18 hours, and after it is cooled to room temperature, grind and sieve to obtain mpg-C 3 N 4 -3 Adsorbents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com