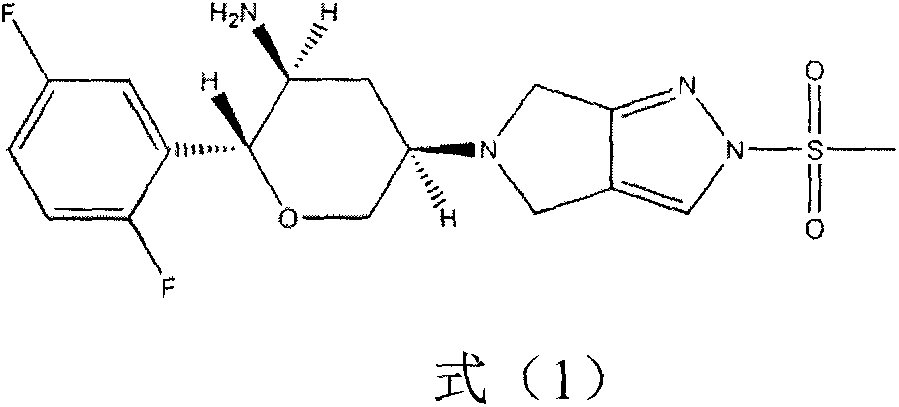

A kind of preparation method of the chiral intermediate of alogliptin

A chiral intermediate, a technology for intermediates, applied in organic chemistry methods, organic chemistry and other directions, can solve the problems of unobtainable raw materials, low yield and high cost, and achieve the effects of novel route, high yield and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

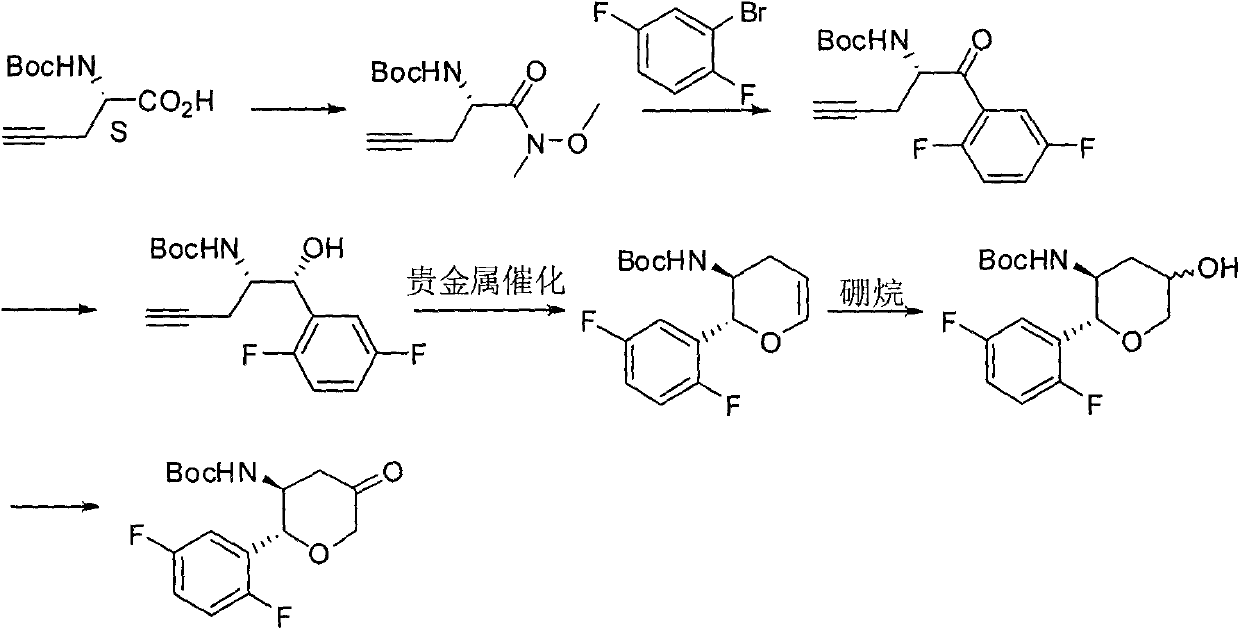

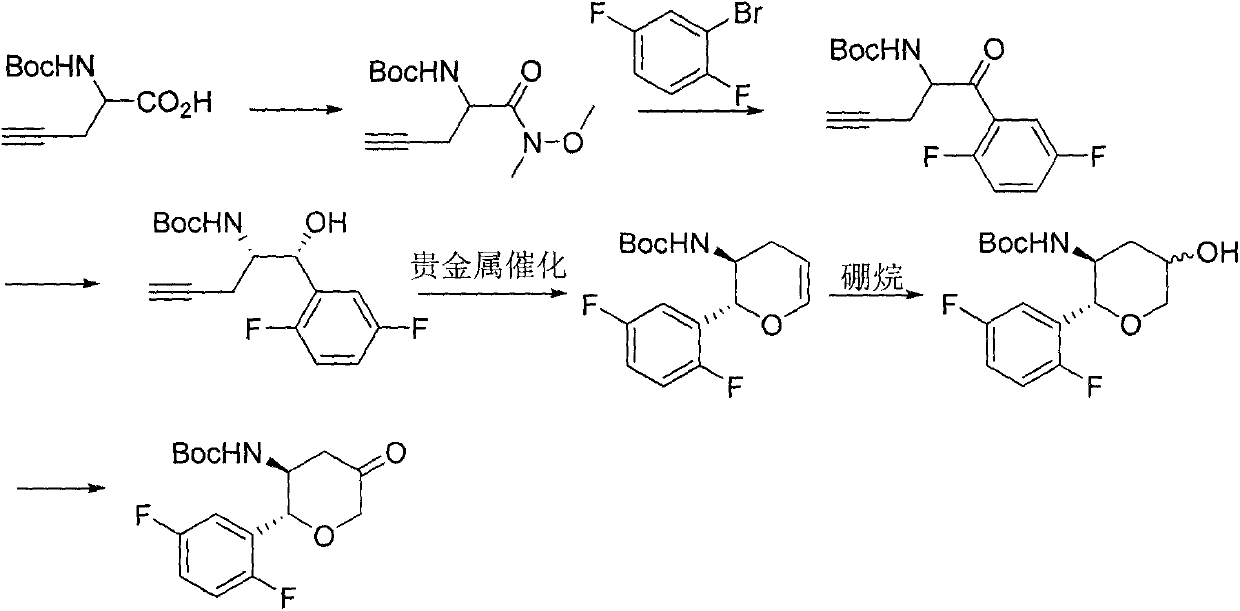

Method used

Image

Examples

Embodiment 1

[0040] The synthesis of embodiment 1 intermediate (I)

[0041]

[0042] Dissolve 20g (0.123mol) (S)-4-benzyl-2-oxazolidinone in 200ml of dichloromethane, add 25.6ml (0.184mol) of triethylamine and 0.45g (0.0037mol) of 4-dimethylamino pyridine. With stirring in an ice bath at 0°C, (15.4 g, 0.15 mol) crotonyl chloride was added dropwise. Maintained at 0°C and stirred for 3h, TLC showed that the raw material had disappeared, added dichloromethane and water, separated the organic layer, dried, concentrated, and obtained intermediate (I) by silica gel column chromatography, 26.8g, yield: 89%, [M +H + ]: 246.1.

Embodiment 2

[0043] The synthesis of embodiment 2 intermediate (II)

[0044]

[0045] Method 1: Replace the nitrogen reaction bottle, add 24.5g (0.1mol) of intermediate (I) and 163ml of anhydrous dichloromethane, lower the temperature to -5°C, and slowly add 32.9g (0.12mol) of trifluoroform Dibutylboron sulfonate, stirred for 10 minutes after dropping. Then 21 ml (0.15 mol) of triethylamine were added dropwise. After the dropwise addition was completed, the temperature was lowered to -70° C., and a solution of 15 g (0.105 mol) of 2,5-difluorobenzaldehyde in 50 ml of dichloromethane was slowly added dropwise. The temperature rose to -10°C over 1 hour and stirred for 1 hour. TLC shows that the reaction is complete, adding 102ml of potassium phosphate buffer successively, 53ml of methyl alcohol and 53ml of 35% hydrogen peroxide, separating the organic layer, washing with saturated sodium bicarbonate, washing with sodium thiosulfate, drying, and separating the intermediate (II) by silica ...

Embodiment 3

[0047] The synthesis of embodiment 3 intermediate (III)

[0048]

[0049] 19.3g (0.05mol) of intermediate (II) was dissolved in 150ml of tetrahydrofuran, and 3.6ml (0.0735mol) of hydrazine hydrate was slowly added dropwise under stirring in an ice bath at 0°C. Maintain stirring at 0 ° C for 2h. After TLC detection showed that the reaction was complete, ethyl acetate and water were added. The organic layer was separated, and the aqueous layer was extracted twice with ethyl acetate. The organic layers were combined, dried over anhydrous sodium sulfate, filtered, concentrated under reduced pressure, and separated by silica gel column chromatography to obtain 11.4 g of intermediate (III), with a yield of 94%. , [M+H + ]: 243.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com