Magnetic Fenton-like catalyst and preparation method thereof

A catalyst and magnetic technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as iron sludge and catalyst recovery difficulties, and achieve good catalytic effect, good dispersibility and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

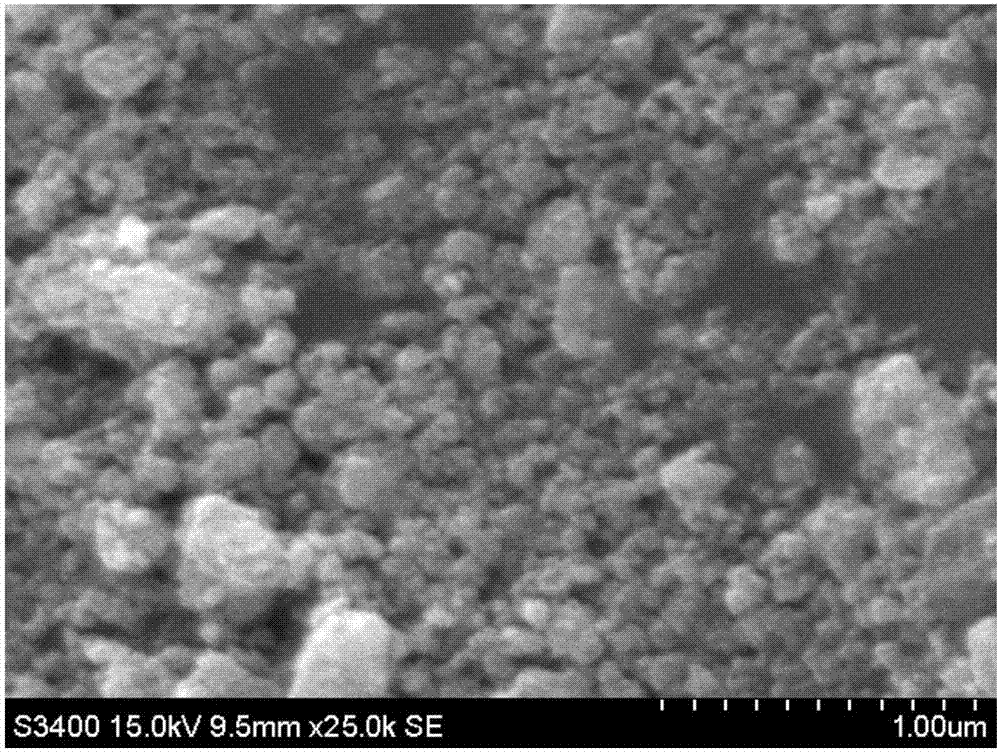

[0029] Example 1: Magnetic Fe 3 o 4 / CeO 2 Preparation of Nanocomposite Catalysts

[0030] First add 100mL 0.2M NaOH into the three-necked flask, then add 0.154g nano-CeO 2 After heating to 80° C. in a water bath, nitrogen gas was passed through the mixture for 3 minutes to remove oxygen in the solution. Then, under electric stirring, 100mL containing 0.400g Fe was added dropwise 2 (SO 4 ) 3 and 2.224g FeSO 4 ·7H 2 The mixed solution of O was maintained at 80°C under nitrogen for 1 h. After the reaction is completed, under an external magnetic field, use the decantation method to wash (5-6 times) the obtained precipitate with twice distilled water. After the washing is completed, vacuum-dry it at a temperature of 60 ° C for 12 hours, and finally take out the dried product and grind it in a mortar. Measure the quality of the product and put it into a weighing bottle for later use.

experiment example 1

[0033] Under normal temperature and pressure, take a certain amount of methylene blue stock solution in 50mL water with a certain pH value to prepare methylene blue solutions with an initial concentration of 20mg / L and different pH values. The pH values of the solutions are 2-7 respectively. Each solution of the same pH value was prepared in duplicate, and the initial absorbance of the solution (A 0 ); another part of the solution added a certain amount of composite catalyst and H 2 o 2 , so that the catalyst concentration after adding is 0.5g / L, H 2 o 2 The concentration is 1.0×10 -3 mol / L, placed in a 250mL Erlenmeyer flask and shaken at 180r / min for 30min in a temperature-controllable shaker. The degraded methylene blue absorbance (A) of the clear liquid was measured with an ultraviolet spectrophotometer, and the degradation rate was calculated according to the measurement results. Three parallel samples were made for each experimental point.

[0034] The results s...

experiment example 2

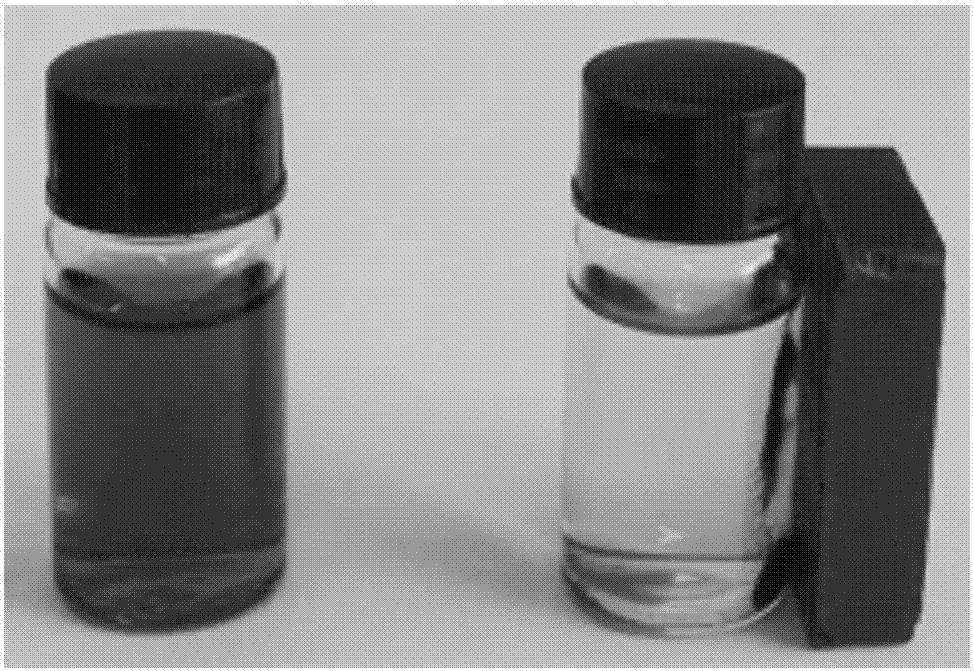

[0036] Under normal temperature and pressure, take a certain amount of methylene blue stock solution in 50mL water to prepare several parts of methylene blue solution with an initial concentration of 20mg / L and a pH value of 4. A certain amount of composite catalyst and different concentrations of H were added to each methylene blue solution 2 o 2 , so that the catalyst concentration after adding is 0.5g / L, H 2 o 2 Concentrations were 0.2, 0.5, 1.0, 2.0 and 3.0 (×10 -3 mol / L), placed in a 250mL Erlenmeyer flask and vibrated at 180r / min for 30min in a temperature-controlled shaker, after the reaction was completed, magnetically separated with a strong magnet, and the supernatant was centrifuged at 6000r / min, and taken twice The supernatant was measured with a UV spectrophotometer for the absorbance (A) of methylene blue after degradation, and the absorbance (A) of the initial methylene blue solution was measured simultaneously. 0 ), and calculate the degradation rate accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com