Method for preparing polyvinyl alcohol/silicon dioxide composite micro-sphere with core-shell structure by one-step process

A silicon dioxide, core-shell structure technology, applied in the fields of biopolymers and medical engineering, can solve the problems of uneven size of composite microspheres, inability to precisely control, and high process requirements, avoiding toxic side effects, improving mechanical strength, and improving biological properties. good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

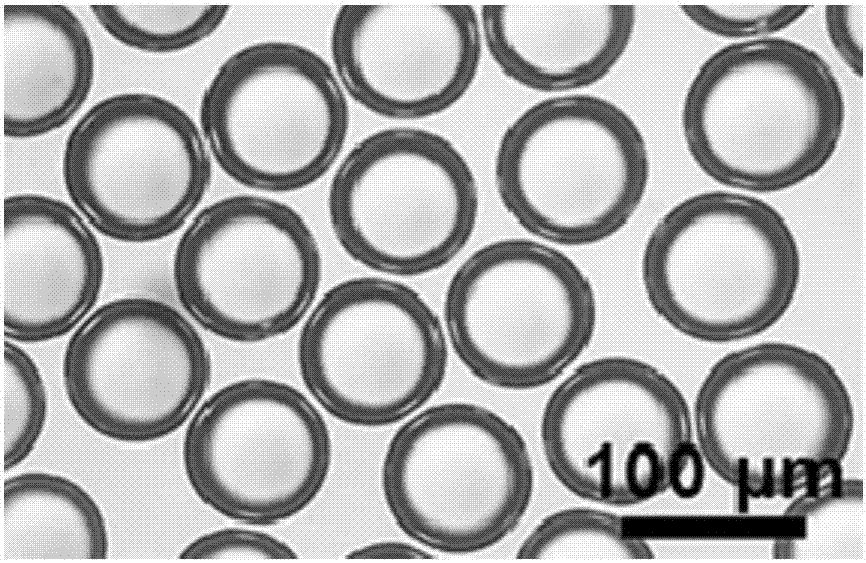

[0033] Dissolve 1.0 g of polyvinyl alcohol PVA124 in 10 mL of deionized water as the water phase by heating deionized water to 95°C under a nitrogen atmosphere; disperse 0.2 g of trimethylchlorosilane-modified silica in 20 ml of mineral oil, as the oil phase. The water phase is a discontinuous phase, and the oil phase is a continuous phase. Through the microfluidic channel of the glass capillary microfluidic chip, the speed of the water phase is controlled to be 1000 microliters / hour, and the speed of the oil phase is 2000 microliters / hour to generate oil. Water-encapsulated droplets ( figure 1 ), after collecting the droplets for 1 hour, put the collected droplets into the refrigerator, control the temperature at about -20°C, and freeze. Take it out after 12 hours and thaw at room temperature. This freezing-thawing cycle was repeated 4 times, and the obtained microspheres were repeatedly washed with n-hexane or acetone and filtered to finally obtain polyvinyl alcohol / silica...

Embodiment 2

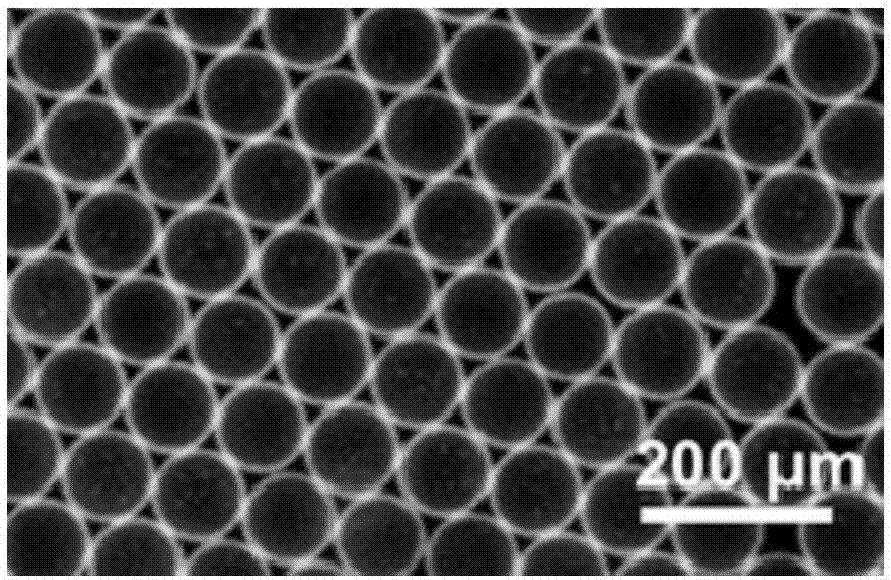

[0035] Example 2 Under a nitrogen atmosphere, by heating deionized water to 95°C, dissolve 1.5g of polyvinyl alcohol PVA124 in 10mL of deionized water as the water phase; disperse 1g of hexadecylchlorosilane-modified silica In 20ml soybean oil, as the oil phase. Make the water phase a discontinuous phase and the oil phase a continuous phase through the microfluidic channel of the glass microfluidic chip, control the speed of the water phase to 1000 microliters / hour, and the speed of the oil phase to 2000 microliters / hour to generate water-in-oil After collecting the droplets for 1 hour, put the collected droplets into the refrigerator, control the temperature at about -30°C, and freeze them. Take it out after 6 hours and thaw at room temperature. Repeat this freeze-thaw cycle 3 times, wash the obtained microspheres repeatedly with n-hexane or acetone and filter, and finally obtain polyvinyl alcohol / silica composite microspheres, which are soaked in water to swell, as shown in...

Embodiment 3

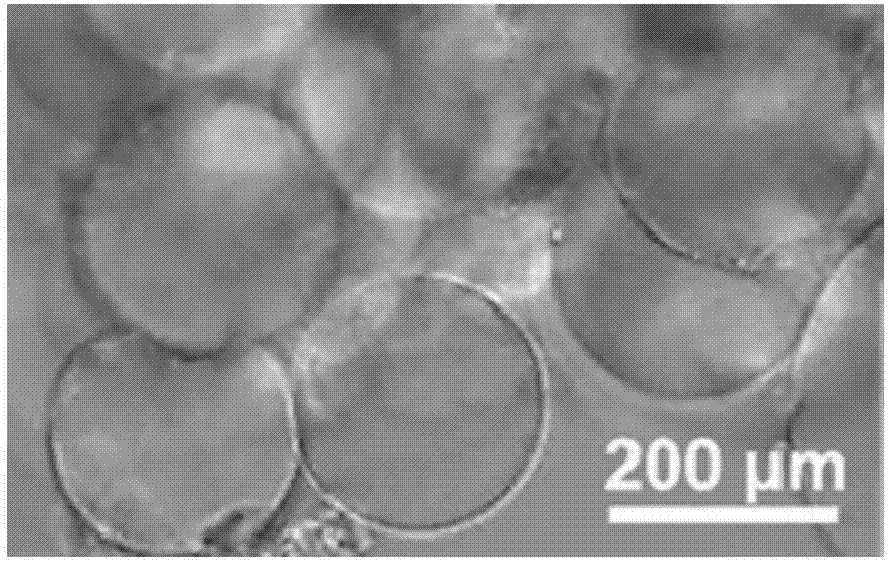

[0037]Example 3 Under a nitrogen atmosphere, by heating deionized water to 95°C, dissolve 2.5g of polyvinyl alcohol PVA124 in 10mL of deionized water as the water phase; disperse 1g of fluorosilane-modified silica in 20ml of fluorine oil (FC-40), as the oil phase. Make the water phase a discontinuous phase and the oil phase a continuous phase through the microfluidic channel of the polymethylsiloxane microfluidic chip, control the water phase speed to 1000 microliters / hour, and the oil phase speed to 2000 microliters / hour, Water-in-oil droplets are generated, and after collecting the droplets for 1 hour, the collected droplets are placed in a refrigerator, and the temperature is controlled at about -20°C for freezing. Take it out after 12 hours and thaw at room temperature. This freeze-thaw cycle was repeated 5 times, and the resulting microspheres were repeatedly washed with n-hexane or acetone and filtered to obtain polyvinyl alcohol / silica composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com