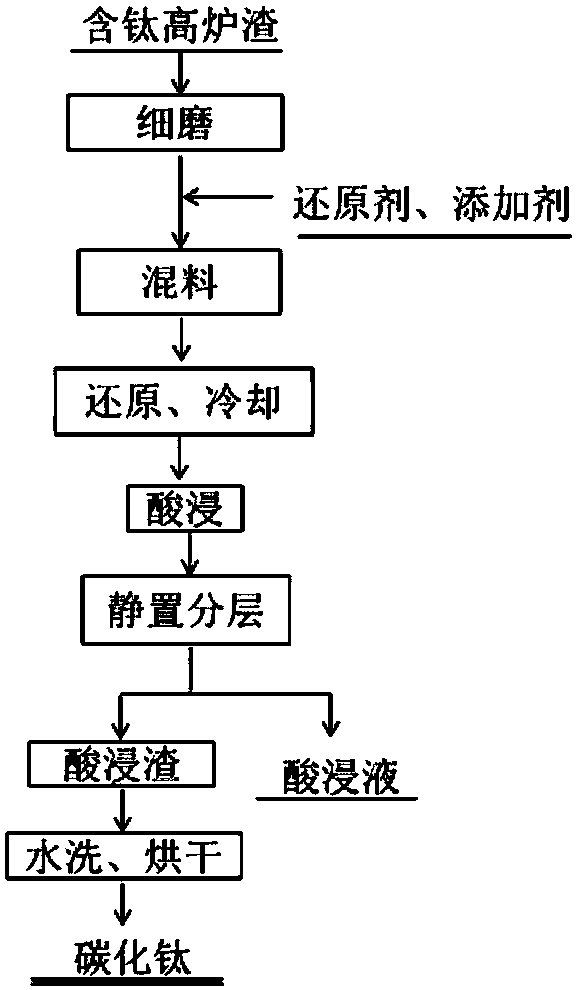

Method for preparing titanium carbide through carbon thermal reduction of titanium-contained blast furnace slag

A blast furnace slag, titanium carbide technology, applied in the direction of titanium carbide and carbide, can solve the problems of long process flow, unstable alloy composition, environmental pollution, etc., and achieve huge economic benefits, stable product quality, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Finely grind 100g of air-cooled titanium-containing blast furnace slag, of which -0.074mm accounts for 89%.

[0030] (2) Mix finely ground titanium-containing blast furnace slag, anthracite coal powder, and boron oxide at a ratio of 100:20:2, mix them evenly, and put them into a graphite crucible.

[0031] (3) When the temperature of the resistance furnace is 1400° C., place the above-mentioned graphite crucible containing the mixture in the resistance furnace for 60 minutes to keep warm. After the heat preservation is over, quickly take out the crucible, place it in a nitrogen atmosphere to cool, and finely grind the cooled reducing material to -0.074mm, accounting for 82%.

[0032] (4) Configure a 6mol / L hydrochloric acid solution, measure the hydrochloric acid solution and the reducing material according to the liquid-solid ratio of 3:1, add them into a four-necked flask respectively, heat and stir, and wait for the hydrochloric acid solution to heat up to 70°C, ...

Embodiment 2

[0036] (1) Finely grind 100 g of air-cooled titanium-containing blast furnace slag, of which -0.074 mm accounts for 85%.

[0037] (2) Mix the finely ground titanium-containing blast furnace slag, anthracite coal powder, and boron oxide at a ratio of 100:20:3, mix them evenly, and put them into a graphite crucible.

[0038] (3) When the temperature of the resistance furnace is 1400° C., place the above-mentioned graphite crucible containing the mixture in the resistance furnace for 90 minutes to keep warm. After the heat preservation is over, quickly take out the crucible, place it in a nitrogen atmosphere to cool, and finely grind the cooled reducing material to -0.074mm, accounting for 80%.

[0039] (4) Configure a 6mol / L hydrochloric acid solution, measure the hydrochloric acid solution and the reducing material according to the liquid-solid ratio of 3:1, add them into a four-necked flask respectively, heat and stir, and wait for the hydrochloric acid solution to heat up to ...

Embodiment 3

[0043] (1) Finely grind 100g of air-cooled titanium-containing blast furnace slag, of which -0.074mm accounts for 88%.

[0044](2) Mix finely ground titanium-containing blast furnace slag, anthracite coal powder, and boron oxide in a ratio of 100:20:5, mix them evenly, and put them into a graphite crucible.

[0045] (3) When the temperature of the resistance furnace is 1300° C., place the above-mentioned graphite crucible containing the mixture in the resistance furnace for 120 minutes to keep warm. After the heat preservation is over, quickly take out the crucible, place it in a nitrogen atmosphere to cool, and finely grind the cooled reducing material to -0.074mm, accounting for 84%.

[0046] (4) Configure a 6mol / L hydrochloric acid solution, measure the hydrochloric acid solution and the reducing material according to the liquid-solid ratio of 3:1, add them to a four-necked flask, heat and stir, and keep the temperature of the hydrochloric acid solution at 80°C for 1.5h , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com