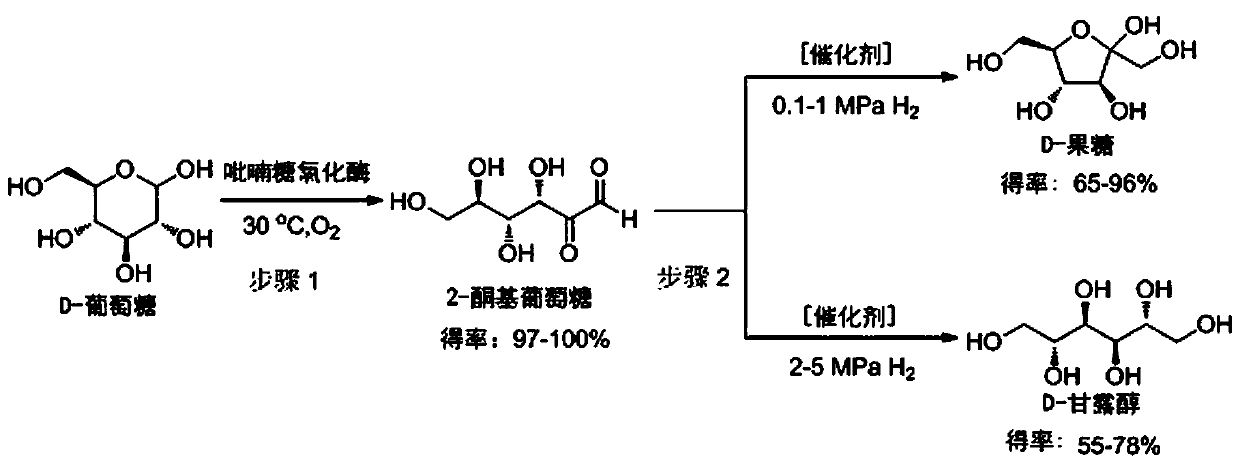

Method for preparing fructose or mannitol in combination with enzymatic catalysis and chemical catalysis

A technology of chemical catalysis and mannitol, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve complex mannitol production process, failure to meet market demand, low yield of fructose and mannitol, etc. problems, to achieve the effect of effectively controlling reaction selectivity, inhibiting the formation of by-products, and high conversion rate of glucose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of nickel / activated carbon: a certain amount of Ni(NO 3 ) 2 ·6H 2 0 was dissolved in water, and slowly added dropwise to the suspension of activated carbon after being completely dissolved, stirred at room temperature for 12 hours, and after being vacuum-dried, the obtained catalyst precursor Ni(NO 3 ) 2 / AC was placed in a tube furnace, activated at 450°C for 6 hours under nitrogen-hydrogen mixture (containing 5-20% hydrogen), and cooled to room temperature to obtain a nickel / activated carbon catalyst with a certain loading capacity.

[0032] Preparation of other metal catalysts: cobalt / activated carbon, nickel / silica, iron / silica, cobalt / silica, cobalt / ASA The preparation process of the catalyst is similar to the preparation of nickel / activated carbon, the difference is that the carrier is used separately Silicon dioxide, activated carbon, and ASA are used, and the supported metals are iron, nickel, etc., and different metal-supported catalysts can be o...

Embodiment 1

[0034](1) According to the mass ratio of D-pyranose oxidase (pyranose oxidase, EC1.1.3.10), catalase, glucose and water in the ratio of 1:1:100:1000, prepare 10g of glucose and 100g of water After mixing to obtain a glucose solution, add 100 mg of D-pyranose oxidase and 100 mg of catalase to the glucose solution, adjust the pH to 5 with citric acid, and then shake the mixture at 30°C (150 rpm) Carry out enzymatic reaction in 12 hours, obtain 2-ketoglucose aqueous solution; Add catalase in this step and can effectively decompose hydrogen peroxide produced in the enzymatic oxidation reaction process;

[0035] In this step, the conversion rate of glucose and the yield of 2-ketoglucose can be qualitatively and quantitatively analyzed by high performance liquid chromatography (HPLC). The detection conditions are as follows: Agilent 1260 liquid chromatograph, column Carbomix Ca-NP10 (10um, 8% cross-linking degree, 7.8×300mm); mobile phase: ultrapure water; column temperature: 80°C; ...

Embodiment 2

[0040] Same as Example 1, only the ethanol in step (2) is replaced with methanol.

[0041] The resulting fructose yield was 93.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com