Graphene lithium battery material and preparation method thereof

A lithium battery material, graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve excellent electrical conductivity, long service life, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

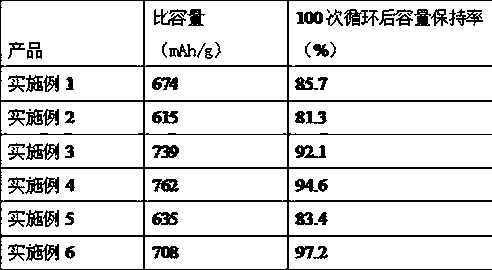

Examples

Embodiment 1

[0025] A graphene lithium battery material, comprising the following raw materials in parts by weight: 100 parts of lithium titanate, 5 parts of three-dimensional graphene, 1.5 parts of rosin resin binder, 1 part of lanthanum oxide rare earth compound, octylphenol polyoxyethylene ether 3 parts of dispersant, 2 parts of lauryl alcohol polyvinyl ether defoamer and 30 parts of ethanol.

[0026] Its preparation method comprises the following steps:

[0027] (1) Add dispersant, defoamer and graphene into an ultrasonic stirrer, then add an organic solvent, and ultrasonically stir for 60 minutes at a frequency of 50kHZ to obtain a graphene dispersion;

[0028] (2) Add the graphene dispersion into the stirrer, then add the binder, stir for 15min at a speed of 200r / min, finally add lanthanum oxide and lithium titanate, and continue stirring for 1h. Vacuum drying at 70°C to obtain the graphene lithium battery material.

Embodiment 2

[0030] A graphene lithium battery material, comprising the following raw materials in parts by weight: 100 parts of lithium titanate, 4 parts of three-dimensional graphene, 0.5 parts of epoxy resin binder, 1 part of polyacrylate binder, cerium nitrate rare earth compound 0.8 parts, 4 parts of sodium metasilicate pentahydrate dispersant, 1.5 parts of nonylphenol polyoxyethylene ether defoamer and 40 parts of acetone.

[0031] Its preparation method comprises the following steps:

[0032] (1) Add dispersant, defoamer and graphene into an ultrasonic stirrer, then add an organic solvent, and ultrasonically stir for 45 minutes at a frequency of 40kHZ to obtain a graphene dispersion;

[0033] (2) Add the graphene dispersion into the stirrer, then add the binder, stir for 20min at a speed of 150r / min, and finally add cerium nitrate and lithium titanate, and continue stirring for 1.5h. Vacuum drying at 80°C to obtain the graphene lithium battery material.

Embodiment 3

[0035] A graphene lithium battery material, comprising the following raw materials in parts by weight: 100 parts of lithium titanate, 3 parts of three-dimensional graphene, 1.5 parts of ethylene-acrylic acid copolymer binder, 1 part of lanthanum sulfate rare earth compound, silicon metasilicon pentahydrate A dispersant mixture of 2 parts of sodium naphthalene sulfonate and 1 part of sodium alkylnaphthalene sulfonate, 1.5 parts of polyoxyethylene polyoxypropylene pentaerythritol ether defoamer and 35 parts of ethyl acetate.

[0036] Its preparation method comprises the following steps:

[0037] (1) Add dispersant, defoamer and graphene into an ultrasonic stirrer, then add an organic solvent, and ultrasonically stir for 30 minutes at a frequency of 60kHZ to obtain a graphene dispersion;

[0038] (2) Add the graphene dispersion into the stirrer, then add the binder, stir for 10min at a speed of 300r / min, and finally add lanthanum sulfate and lithium titanate, and continue stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com