Ferment liquid for pets to drink and preparation method of ferment liquid

An enzyme and pet technology, applied in additional food elements, applications, animal feed, etc., can solve problems such as material selection, ratio, temperature setting, and unreasonable production process design, inability to retain active ingredients of enzymes, and inability to effectively control fermentation time, etc. , to reduce the production of bad flavor and harmful substances, promote mass reproduction, and soften the sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

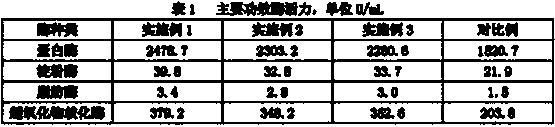

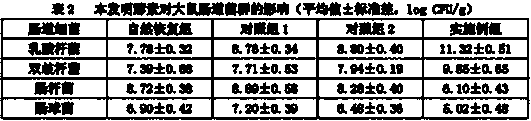

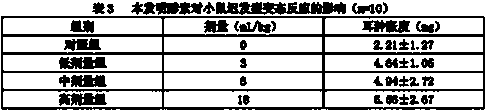

Examples

Embodiment 1

[0037] (1) 20 apples, 15 bananas, 35 dragon fruit, 10 black wolfberries, 5 lemons, 3 onions, washed, ozone disinfected, and ozone concentration 30-50mg / m 3 , The time is 2-3h, peeled and cut into small pieces, smashed and put into a sterile reactor, processed by ultrasonic at a frequency of 85KHz, at 50-55℃ for 30min to obtain a slurry;

[0038] (2) Pour nitrogen into the fermentor to saturate it, add the slurry obtained in step 1 to the fermentor, and then add 5 parts of glucose, 5 parts of enzyme active agent, 25 parts of bacterial liquid A, and stir evenly at 28-35 Primary fermentation at a temperature of ℃ for 10-15 days; among them, the enzyme activator is from Lulose: Xylitol: R(+)-lipoic acid-L-lysine salt crystal form I: guar gum, According to the mass ratio of 3:1:2:0.5, the crystal form I of the R(+)-lipoic acid-L-lysine salt refers to the use of Cu-Kα radiation, and its X-ray powder In the diffraction pattern, there are diffraction peaks at 2θ values 5.102, 7.589, 10...

Embodiment 2

[0045] (1) 10 parts of apple, 20 parts of banana, 40 parts of dragon fruit, 15 parts of black wolfberry, 10 parts of lemon, 2 parts of onion, wash, ozone disinfection, ozone concentration 30-50mg / m 3 , The time is 2-3h, peeled and cut into small pieces, smashed and put into a sterile reactor, processed by ultrasonic at a frequency of 90KHz, at 50-55℃ for 50min to obtain a slurry;

[0046] (2) Pour nitrogen into the fermentor to saturate it, add the slurry obtained in step 1 to the fermentor, and then add 5 parts of glucose, 5 parts of enzyme active agent, 25 parts of bacterial liquid A, and stir evenly at 28-35 Primary fermentation at a temperature of ℃ for 10-15 days; among them, the enzyme activator is from Lulose: Xylitol: R(+)-lipoic acid-L-lysine salt crystal form I: guar gum, According to the mass ratio 4:2:3:1, the crystal form I of the R(+)-lipoic acid-L-lysine salt refers to the use of Cu-Kα radiation, and its X-ray powder In the diffraction pattern, there are diffractio...

Embodiment 3

[0053] (1) 15 parts of apple, 15 parts of banana, 35 parts of dragon fruit, 10 parts of black wolfberry, 5 parts of lemon, 3 parts of onion, wash, ozone disinfection, ozone concentration 30-50mg / m 3 , The time is 2-3h, peeled and cut into small pieces, smashed and put into a sterile reactor, processed by ultrasonic at a frequency of 85KHz, at 50-55℃ for 40min to obtain a slurry;

[0054] (2) Pour nitrogen into the fermentor to saturate it, add the slurry obtained in step 1 to the fermentor, and then add 5 parts of glucose, 5 parts of enzyme active agent, 25 parts of bacterial liquid A, and stir evenly at 28-35 Primary fermentation for 10-15 days at a temperature of ℃; among them, the enzyme activator is made up of Lulose: Xylitol: R(+)-Lipoic Acid: Guar Gum, according to the mass ratio of 3:2:2:1 The R(+)-lipoic acid refers to dextro-lipoic acid; the bacterial liquid A is composed of the following mass percentage of raw materials: water 90%, soybean meal 7%, yeast 2%, lactic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com