Preparation method of chromium-doped ternary material

A technology of ternary materials and positive electrode materials, which is applied in the manufacture of electrical components, hybrid/electric double layer capacitors, structural parts, etc., can solve the problems of difficult consistency of the chemical composition of samples at room temperature, incomplete precipitation of nickel and cobalt ions, and large differences in precipitation conditions Large and other problems, to achieve the effect of excellent discharge performance, good consistency, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Weigh nickel acetate, cobalt acetate, manganese acetate, lithium hydroxide and Cr respectively according to the molar ratio of nickel, cobalt, manganese, lithium and chromium ions: 0.5:0.19:0.3:1:0.01 2 o 3 . Nickel acetate, cobalt acetate, manganese acetate and Cr 2 o 3 Mix to obtain mixture 1. Add 5 times the volume of deionized water of the total volume of mixture 1, add ammonia water dropwise under continuous stirring until the acidity of the solution is pH 12.5, add weighed lithium hydroxide, and age for 24 hours in a nitrogen atmosphere at 85°C , to prepare precursor 2. Precursor 2 was heated at 230° C. under a vacuum condition of 0.1 atmosphere to prepare dry precursor 3 . Precursor 3 was placed in an oxygen atmosphere, heated from room temperature to 850 °C at a rate of 5 °C / min, and cooled to room temperature to prepare a layered α-NaFeO 2 Structured zirconium-doped ternary cathode material.

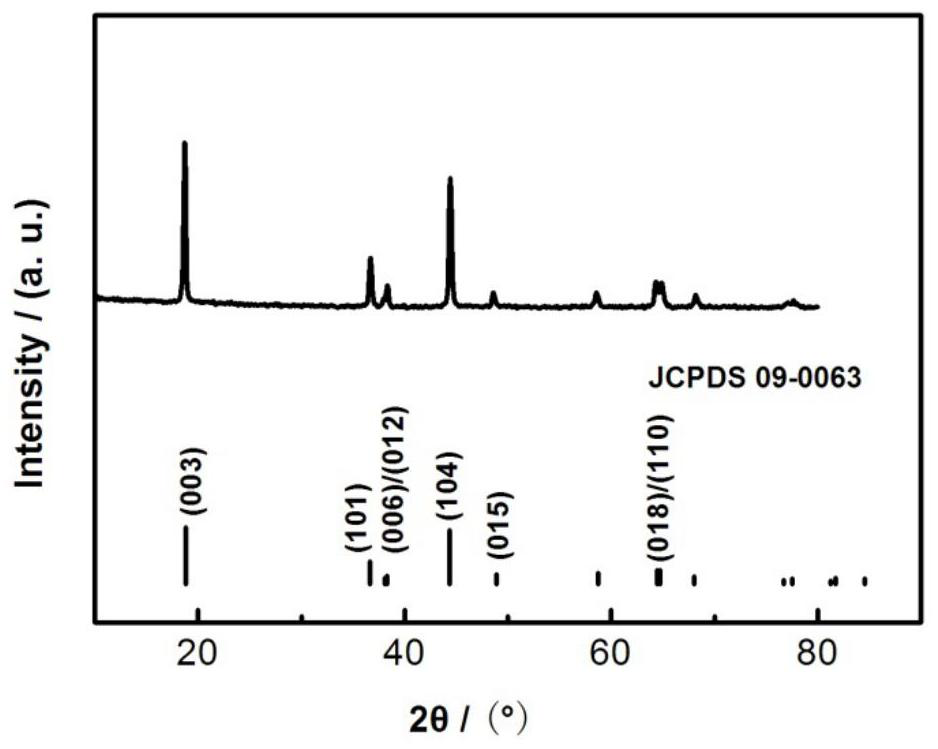

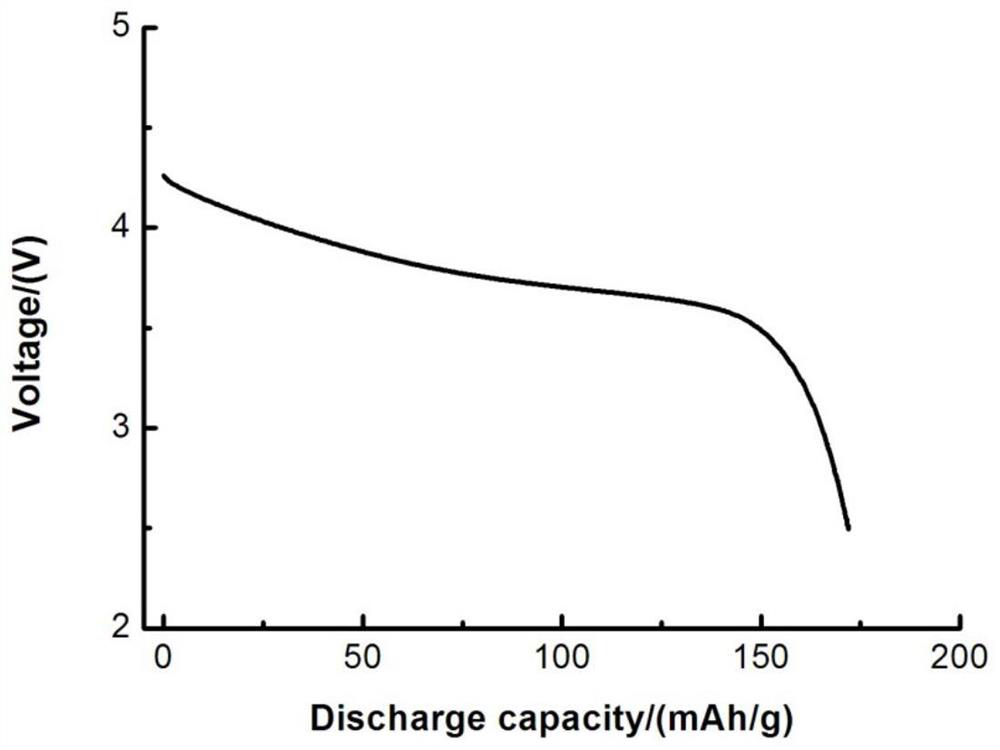

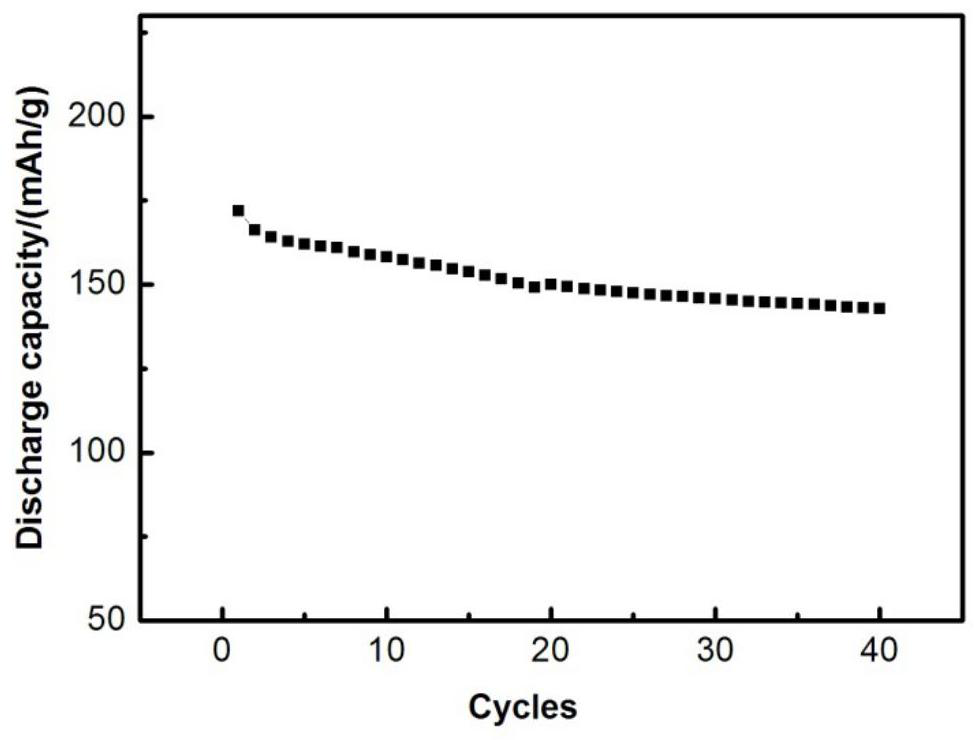

[0053] The ternary material satisfies the following character...

Embodiment 2

[0055] Weigh nickel oxide, cobalt nitrate, manganese oxide, lithium citrate and Cr(OH) respectively according to the molar ratio of nickel, cobalt, manganese, lithium and chromium ions: 0.49:0.12:0.30:0.97:0.06 3 . Nickel oxide, cobalt nitrate, manganese oxide and Cr(OH) 3 Mix to obtain mixture 1. Add 1 times the volume of distilled water of the total volume of the mixture 1, add ammonia water dropwise under the condition of continuous stirring until the acidity of the solution is pH 12.0, add the weighed lithium citrate, and age under an argon atmosphere at 65°C for 48 hours to prepare Precursor 2 was obtained. Precursor 2 was spray-dried at 260 °C to prepare dry precursor 3. Precursor 3 was placed in an oxygen atmosphere, heated from room temperature to 880 °C at a rate of 8 °C / min, and cooled to room temperature to prepare a layered α-NaFeO 2 Structured chromium-doped ternary cathode material.

[0056] The ternary material satisfies the following characteristics at the...

Embodiment 3

[0058] Weigh nickel nitrate, cobalt acetate, manganese oxide, lithium nitrate and Cr(OH) respectively according to the molar ratio of nickel, cobalt, manganese, lithium and chromium ions: 0.51:0.19:0.30:1.08:0.08 3 . Nickel nitrate, cobalt acetate, manganese oxide and Cr(OH) 3 Mix to obtain mixture 1. Add methanol 20 times the volume of the total volume of mixture 1, add ammonia water dropwise under continuous stirring until the acidity of the solution is pH 9.5, add weighed lithium nitrate, and age for 38 hours in a helium atmosphere at 90°C to prepare Precursor 2 was obtained. Precursor 2 was heated at 260° C. under a vacuum condition of 0.9 atmospheric pressure to prepare dry precursor 3 . Precursor 3 was placed in an oxygen atmosphere, heated from room temperature to 800 °C at a rate of 0.1 °C / min, and cooled to room temperature to prepare a layered α-NaFeO 2 Structured chromium-doped ternary cathode material.

[0059] The ternary material satisfies the following char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com