Method for building vascularized tissue engineering periosteum

A tissue-engineered bone and vascularization technology, applied in the field of materials, can solve problems such as the inability of vascularized fibrous membrane to meet clinical needs, and achieve the effects of shortening the healing process, simple method, and shortening integration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1. Preparation of chitosan / cellulose acetate cellulose membrane:

[0033] Chitosan and cellulose acetate (mass ratio 2:1) were dissolved in a mixed solvent of dimethylacetamide and acetone to obtain 8% composite spinning solution. Then the chitosan / cellulose acetate composite fiber membrane was prepared by electrospinning technology, and then the resulting chitosan / cellulose acetate composite fiber membrane was vacuum-dried in a vacuum oven for 24 hours to fully volatilize the solvent; the electrospinning voltage 16kV, propel the spinning solution at a speed of 1.2mL / h, set the distance to the receiver at 12cm, the spinning temperature at 25°C, and the relative humidity at 40%;

[0034] Soak in 100% alcohol for 30 minutes, soak in 95% alcohol for 5 minutes, soak in 90% alcohol for 5 minutes, soak in 85% alcohol for 5 minutes, soak in 80% alcohol for 5 minutes, soak in 70% alcohol for 5 minutes, soak in 60% alcohol for 5 minutes, 50 Soak in % alcohol for 5 minutes,...

Embodiment 2

[0041] Step 1. Preparation of acetate / cellulose micro / nanofibrous membrane:

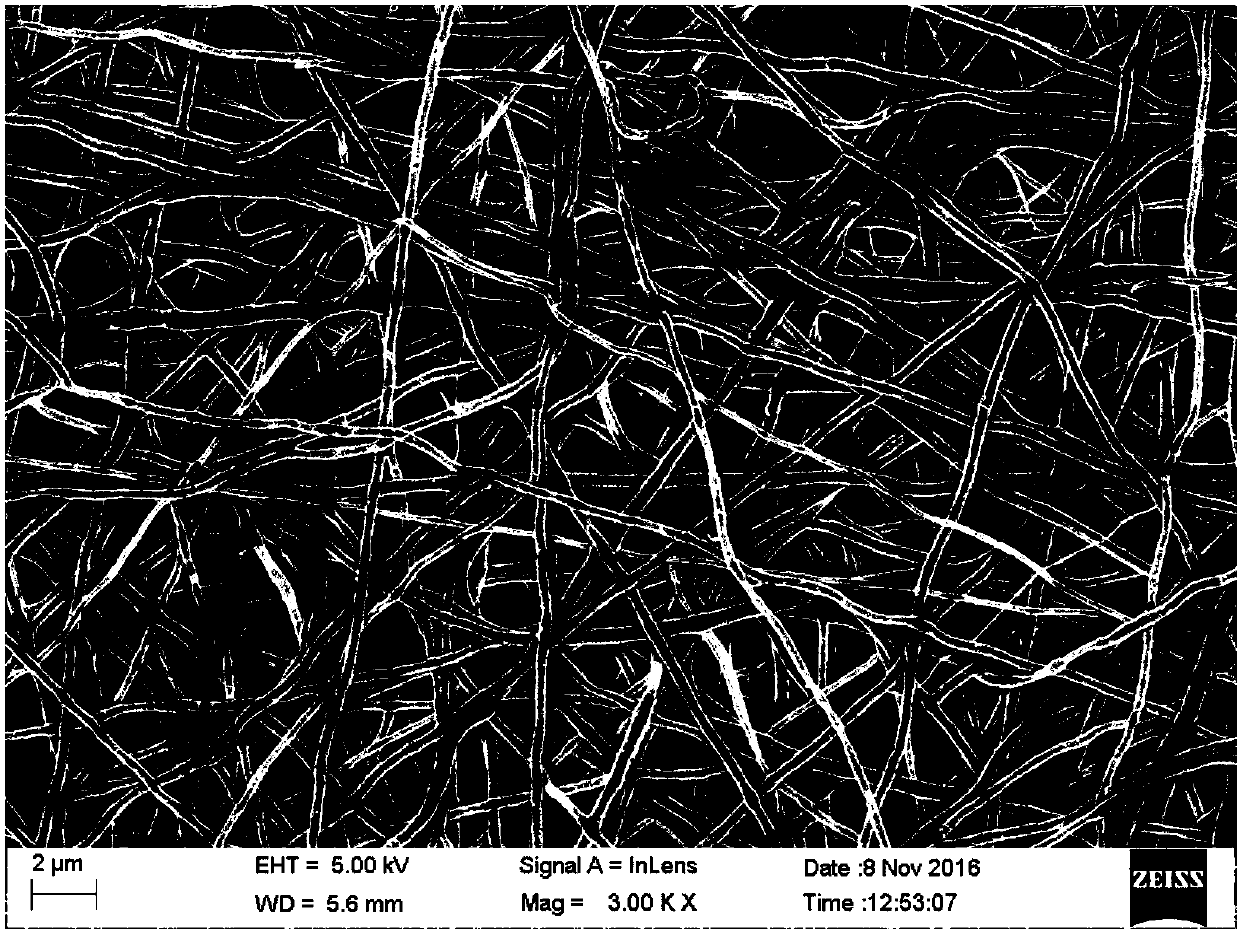

[0042] Cellulose acetate was dissolved in a mixed solution of acetone and dimethylacetamide (mass ratio 2:1) to obtain a 16 wt% acetic acid / cellulose mixed solution. Then, the acetate / cellulose micro / nanofibrous membrane was prepared by electrospinning. Parameter setting: temperature is 25°C, relative humidity is 50%, voltage is 16kV, receiving distance is 15cm, solution flow rate is 1mL / h;

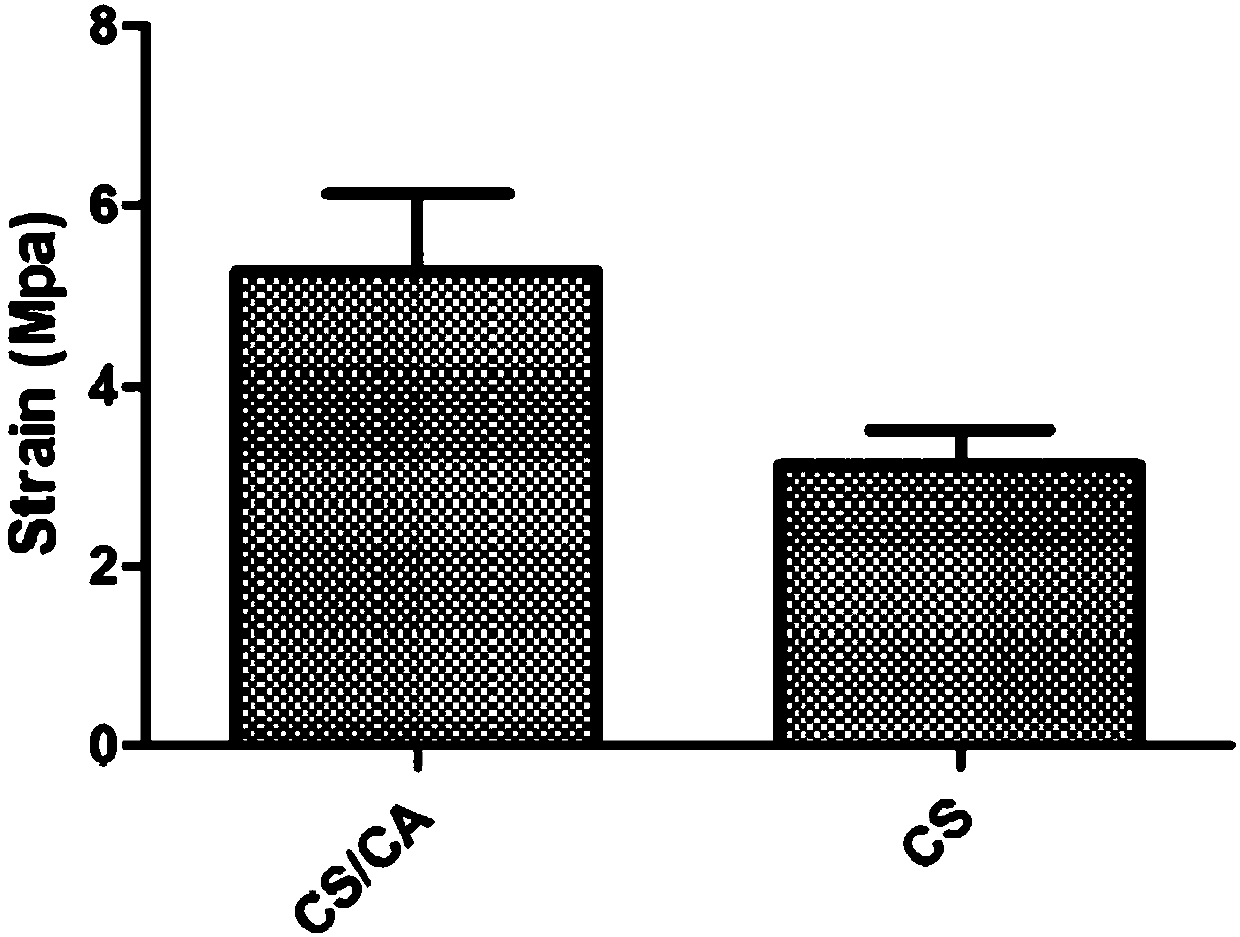

[0043] Vacuum-dry the prepared cellulose acetate micro / nanofiber composite membrane at 60°C to fully evaporate the residual solvent; place the dried micro / nanofiber membrane in 0.05mol / L sodium hydroxide solution for 7 days and dry it at room temperature Ultraviolet radiation disinfection for 24 hours; figure 2 As shown, the tensile test shows that the tensile force of the acetate / cellulose micro / nanofiber membrane is greater than that of the pure chitosan nanofiber membrane; it proves that the mechanical pro...

Embodiment 3

[0049] Step 1. Preparation of silk fibroin / polycaprolactone composite nanofiber membrane:

[0050] Take a certain amount of silk fibroin and polycaprolactone and dissolve them in hexafluoroisopropanol to prepare a mixed solution with a mass fraction of 3% of silk fibroin and polycaprolactone at 4:1; then use electrospinning technology to Preparation of silk fibroin / polycaprolactone composite nanofiber membrane, parameter settings: temperature 25°C, relative humidity 40%, voltage 15kV, receiving distance 12cm, solution flow rate 1mL / h;

[0051] Soak in 100% alcohol for 30 minutes, soak in 95% alcohol for 5 minutes, soak in 90% alcohol for 5 minutes, soak in 85% alcohol for 5 minutes, soak in 80% alcohol for 5 minutes, soak in 70% alcohol for 5 minutes, soak in 60% alcohol for 5 minutes, 50 Soak in % alcohol for 5 minutes, soak in double distilled water for 10 minutes;

[0052] The obtained silk fibroin / polycaprolactone composite nanofiber membrane was vacuum-dried at 60°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com