Yellow carbon quantum dot fluorescent powder as well as preparation method and application

A technology of carbon quantum dots and phosphors, applied in the field of phosphors, to achieve the effects of good color stability, good thermal stability, and good excitation wavelength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Synthesis of yellow carbon quantum dots: Disperse 1.4 g of o-phenylenediamine into 70 mL of deionized water, stir magnetically at room temperature until the o-phenylenediamine is completely dissolved; transfer it to a 100 mL polytetrafluoroethylene reactor, 200 ℃ hydrothermal reaction for 12 hours.

[0046] Purification and purification of carbon quantum dots: After the reaction, cool to room temperature to collect the liquid, centrifuge at 11000 rp / m for 5 min, and then filter the sample with a 0.22 μm microporous membrane to remove residual macromolecular particles that have not completely reacted; Finally, the sample was dialyzed using a dialysis bag with a molecular cutoff of 500 Da to obtain a pure, impurity-free carbon quantum dot solution.

[0047] Characterization of particle morphology of carbon quantum dots: The particle morphology of the synthesized carbon quantum dots was observed by transmission electron microscopy ( image 3 ), it can be seen that the syn...

Embodiment 2

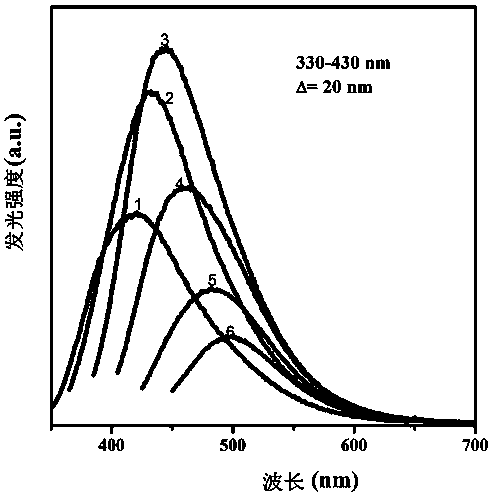

[0050] Preparation of yellow carbon quantum dot phosphor: Take 5 mL of dialyzed carbon quantum dot solution in a beaker, add 5 g of starch (the mass ratio of starch and carbon quantum dots is 50:1), and add deionized water to 30 mL , magnetically stirred at room temperature for 6 hours; after the stirring was completed, the sample was centrifuged, the supernatant was poured off, and the precipitate was vacuum-dried at 70 °C for 2 hours; then the precipitate was taken out and ground evenly, and the fluorescence spectrometer was used to detect its different wavelengths ( 350~510 nm) excitation emission spectrum ( Figure 5 ). It can be seen that the luminous position of the carbon quantum dot phosphor does not change with the change of the excitation wavelength, and emits yellow light with a peak wavelength of 545 nm under different excitation wavelengths, which has good color stability, which is similar to that of yellow carbon The luminescent properties of the quantum dot sol...

Embodiment 3

[0052] The fluorescent powder is used to prepare a blue chip-type white LED device. In this embodiment, a strip-shaped blue light chip is used, and its luminous peak is 450 nm. The specific implementation method is as follows: take 0.25 g of the prepared yellow carbon quantum dot phosphor powder and 0.5 g of optical special glue, grind and mix until a uniform suspension is formed, and then use a dispenser to evenly drop the suspension into the concave of the blue-ray chip. In the tank, cover the blue light chip; then put the chip in a vacuum drying oven at 150 °C to cure the coating layer at a constant temperature in vacuum to obtain a white LED planar light source device, which emits bright white light after being lit ( Figure 9 ), the color temperature is 8946K, and the color rendering index is close to 80. Figure 9 Middle (a) Optical parameter diagram; (b) Device physical diagram.

[0053] Therefore, the phosphor powder provided by the present invention can be effective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com