Hydrated alumina composition containing composite molecular sieve, catalyst, preparation methods of hydrated alumina composition containing composite molecular sieve, and catalyst, and hydroisomerization method

A technology of hydrated alumina and composition, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of strong pseudo-boehmite viscosity, secondary dust pollution, and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

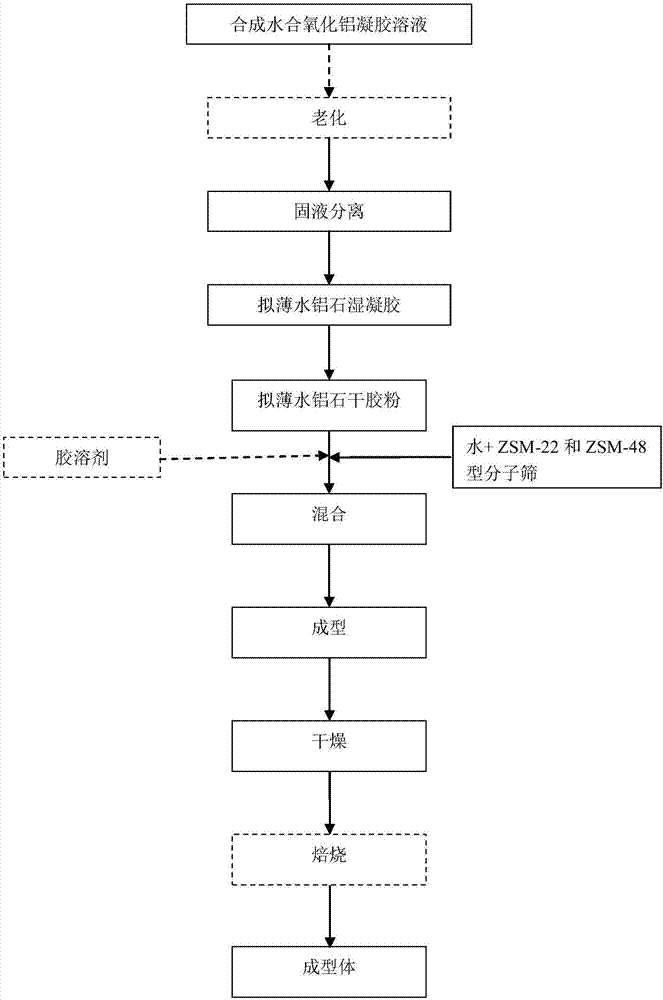

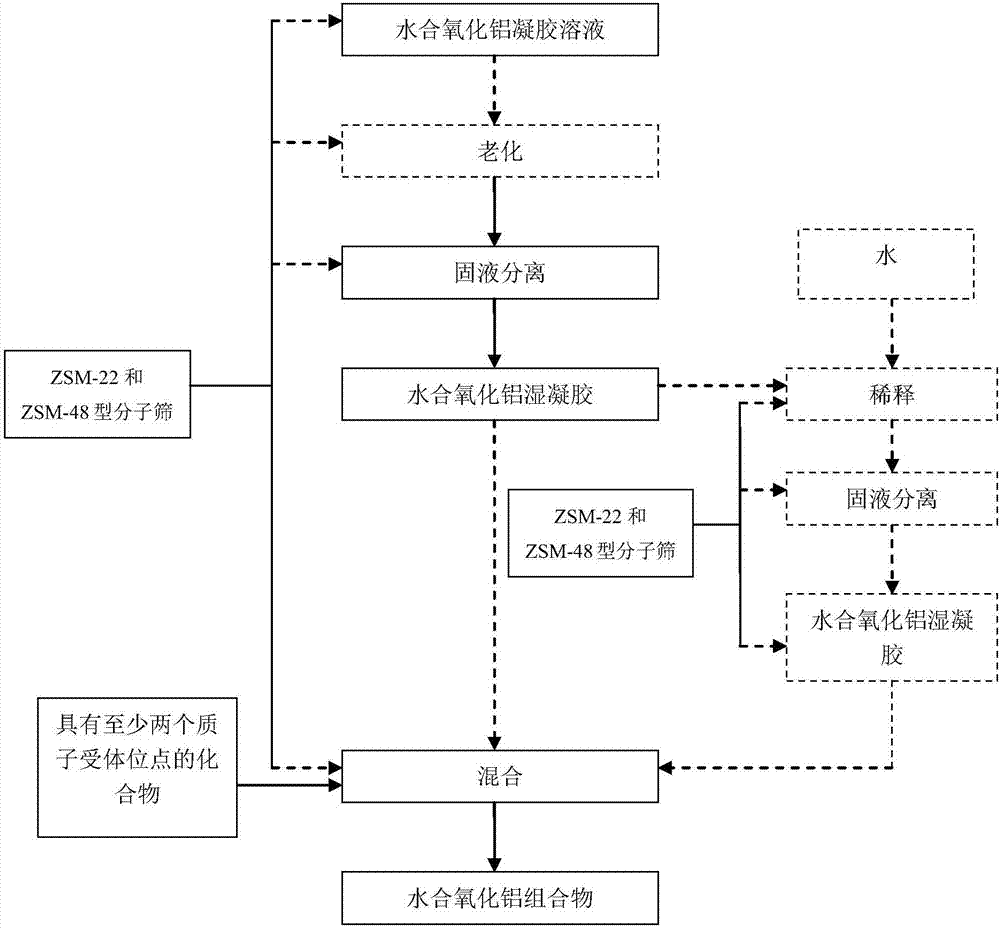

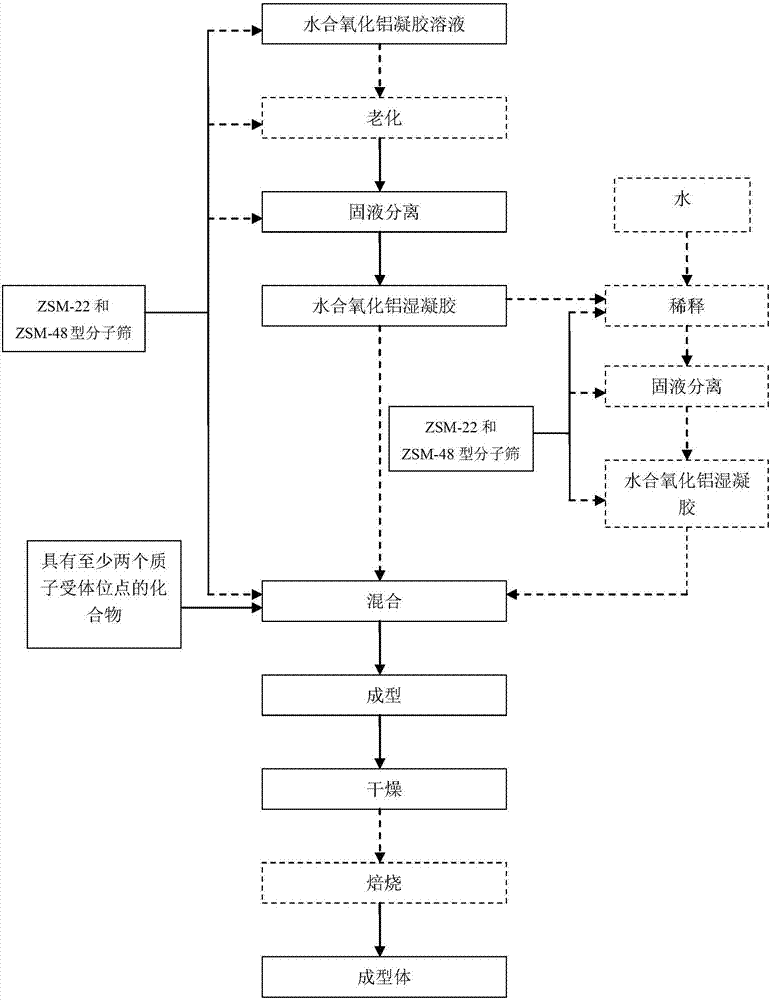

[0106] According to the preparation method of the hydrated alumina composition of the present invention, the raw material mixture contains hydrated alumina wet gel, ZSM-22 and ZSM-48 molecular sieves, and a compound having at least two proton acceptor sites. The compounds with at least two proton acceptor sites and their types, as well as the ZSM-22 and ZSM-48 molecular sieves and their types have been described in detail above, and will not be repeated here.

[0107] The hydrated alumina wet gel can be synthesized by conventional methods, for example, by one or more methods of precipitation method (including acid method and alkali method), hydrolysis method, seed separation method and rapid dehydration method. It is generally obtained by optionally aging the hydrated alumina gel solution, washing and solid-liquid separation.

[0108] The precipitation method includes acid method and alkali method. In the acid method, the aluminum salt is precipitated with a basic compound. The a...

Embodiment 1

[0239] The hydrated alumina wet gel used in this example is a simulated hydrated alumina gel solution prepared by the acid method (sodium metaaluminate-aluminum sulfate method, taken from Sinopec Changling Branch) by washing and filtering. The boehmite wet cake (the wet cake is numbered SLB-1), the i value of the wet cake is 80.2% after measurement.

[0240] (1) Add 5.48kg of ZSM-22 and ZSM-48 molecular sieves (product of Sinopec Catalyst Branch Company, with a silicon-to-aluminum ratio of 50, 98% by weight on a dry basis, to 50kg of wet cake SLB-1, ZSM-22 and ZSM -48 mass ratio 1), then add 10kg of water and mix for 5 minutes, and then filter the slurry with a belt filter to obtain 15.2kg of wet cake SLBZ-1. The i value of the wet cake SLBZ-1 was determined to be 80.2%; after the wet cake SLBZ-1 was calcined at 600°C for 3 hours, it was determined that the dry basis of alumina and ZSM-22 and ZSM-48 molecular sieves The weight ratio to (after calcination at 600°C for 3 hours) is...

Embodiment 2

[0252] (1) Mix 5kg of wet filter cake numbered SLBZ-1 with 500g deionized water for 1 minute, and then send the obtained slurry into the plate and frame filter press, adjust the pressure of the plate and frame to 0.7MPa and maintain In 15 minutes, a wet cake (numbered as LBZ-1) was obtained. It was determined that the i value of the wet cake numbered LBZ-1 was 63%.

[0253] (2) Put 300g of wet filter cake numbered LBZ-1 in a beaker, add 4.3g of hydroxyethyl methylcellulose (purchased from Shanghai Huiguang Fine Chemical Co., Ltd., the same below) and 1.7g of sesame powder ( The content of galactomannan was 85% by weight, purchased from Beijing Chemical Reagent Co., Ltd., and after stirring with a mechanical stirrer for 10 minutes, the hydrated alumina composition of the present invention was obtained, the properties of which are listed in Table 1.

[0254] (3) The hydrated alumina composition prepared in step (2) is extruded on an F-26 type twin screw extruder using a circular ori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com