High-temperature-resistant, easy-to-dissolve and flame-retardant fluorinated polyaryl ether nitrile resin and preparation method thereof

A technology of polyarylether nitrile resin and polyarylether nitrile, which is applied in the field of high-temperature-resistant, soluble, flame-retardant fluorine-containing polyarylether nitrile resin and its preparation, and can solve the problem of difficult removal of high-boiling-point polar solvents and increase of PEN Dielectric loss, affecting the dielectric properties of PEN, etc., to achieve good mechanical strength, good flame retardant properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

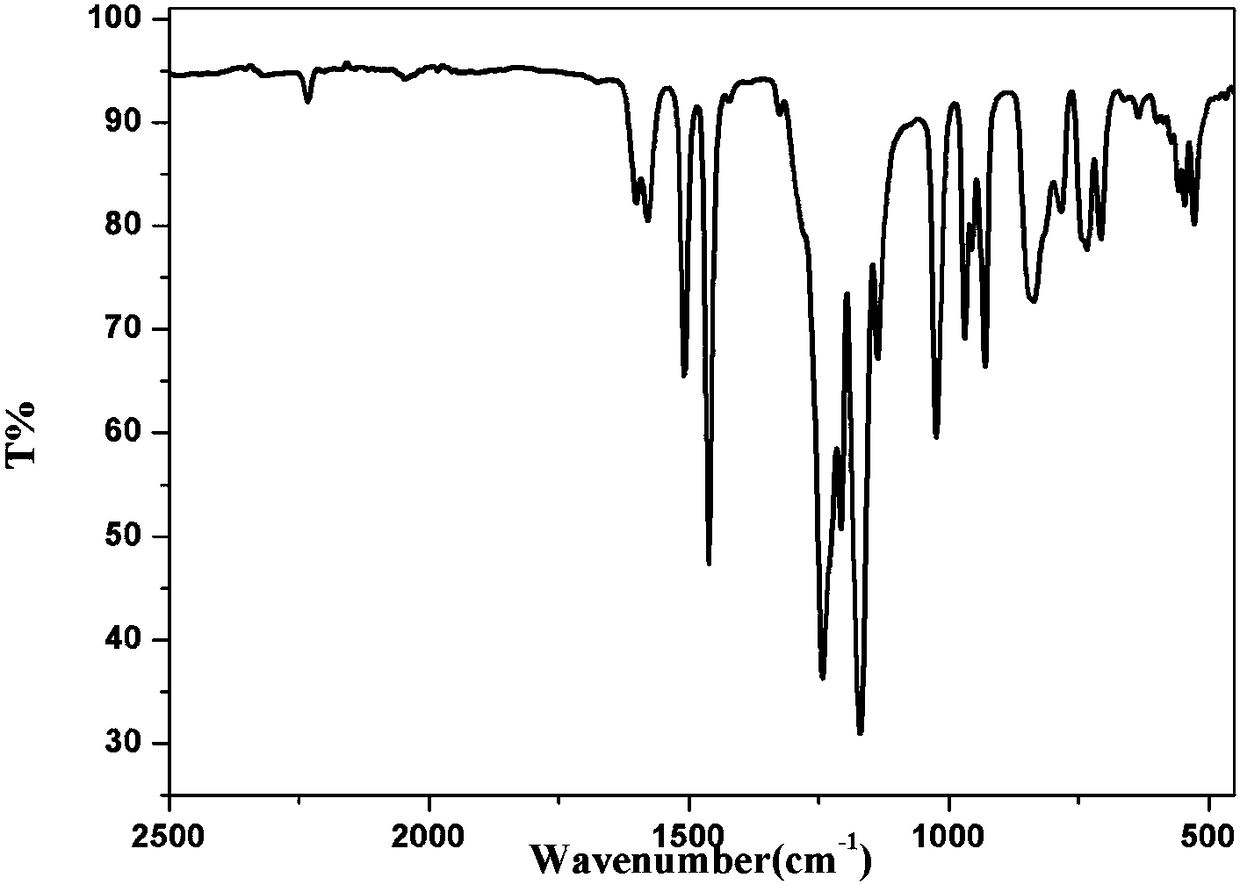

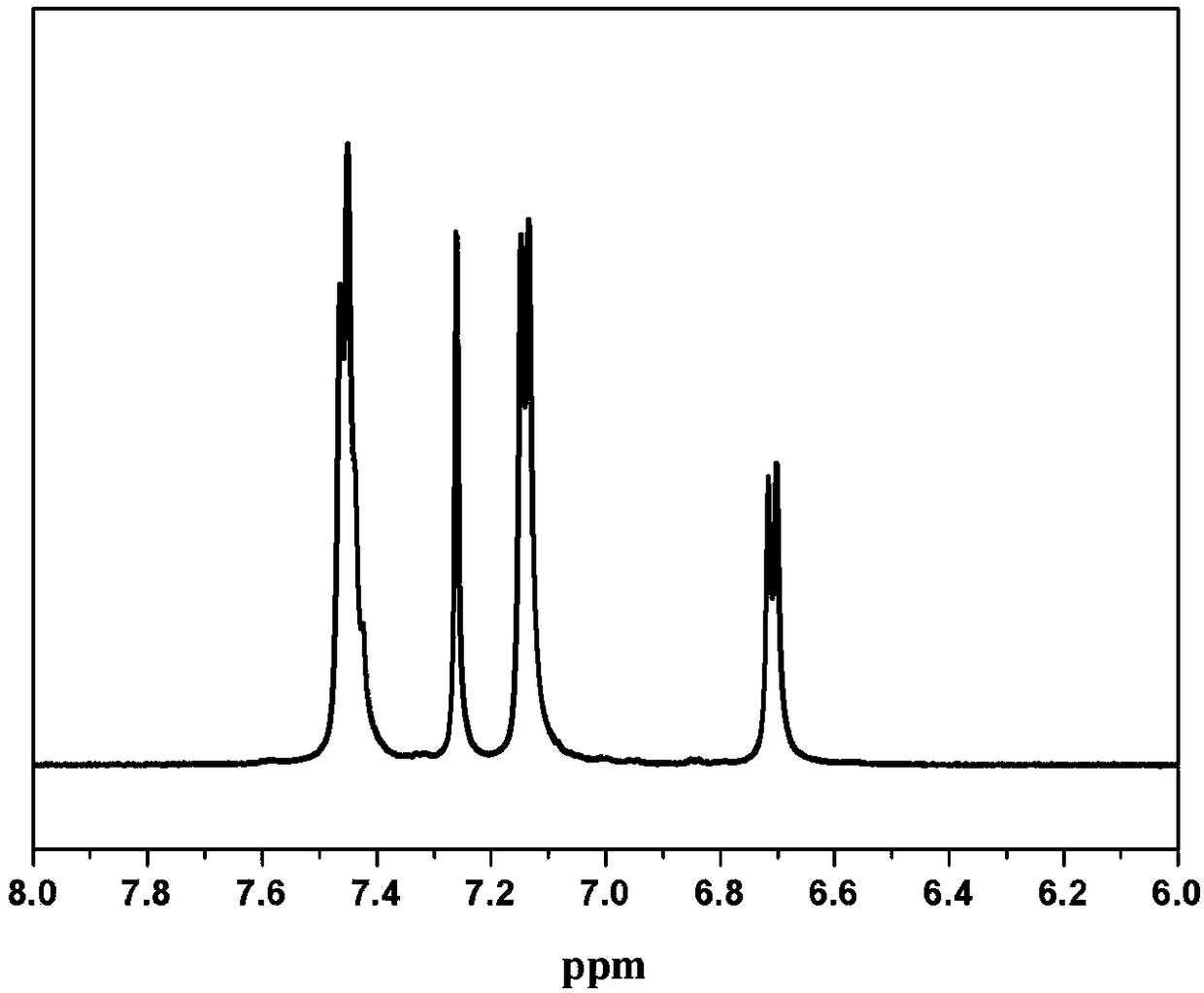

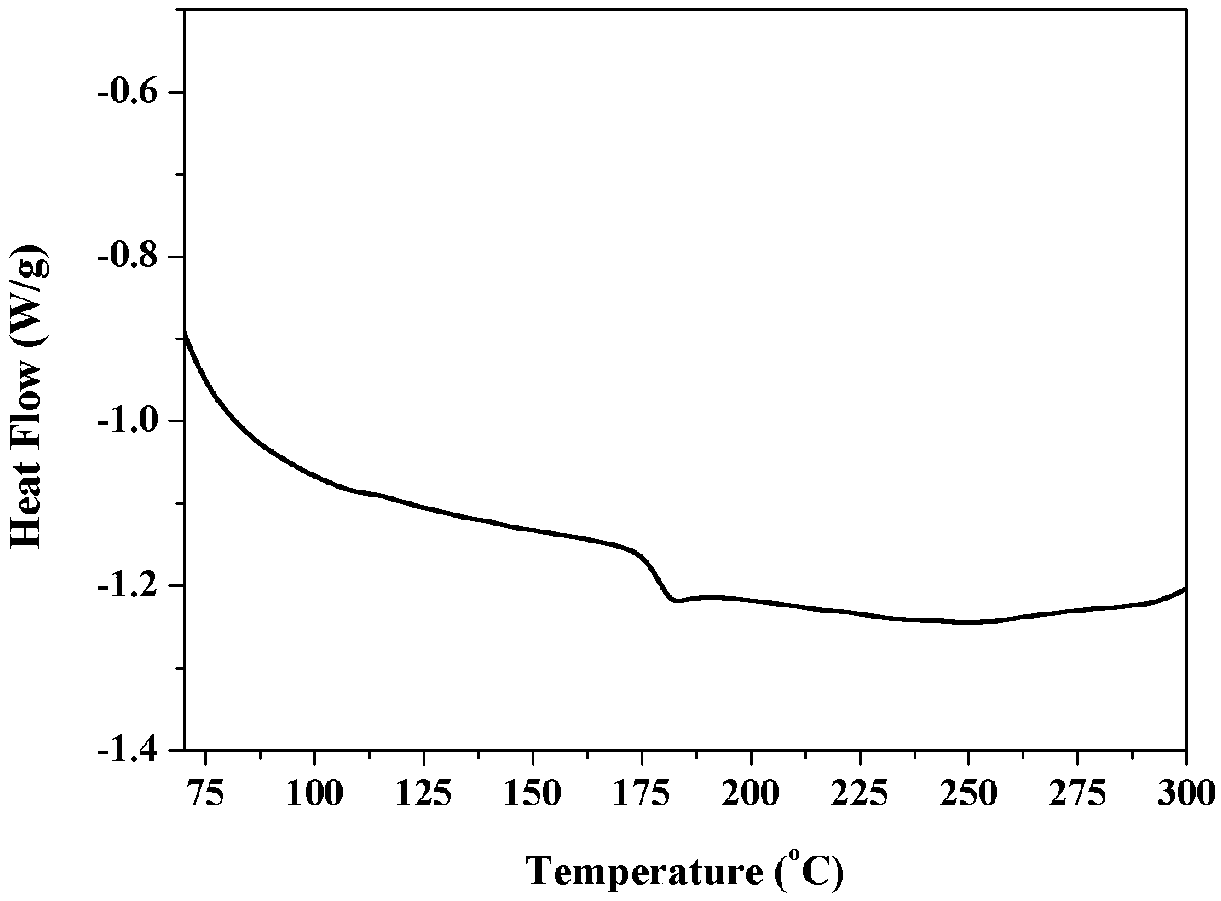

[0030] The preparation method of fluorine-containing polyarylether nitrile resin of the present invention comprises the following steps:

[0031] Step 1: Take the raw materials, use bisphenol AF and 2,6 dichlorobenzonitrile as the main raw materials, and use sulfolane, toluene and potassium carbonate as auxiliary raw materials; wherein sulfolane is the solvent, toluene is the dehydrating agent, and potassium carbonate is the condensation polymerization reaction The catalyst, the molar ratio between the amount of each raw material is: bisphenol AF: 2,6 dichlorobenzonitrile: sulfolane: toluene: potassium carbonate=1:1:(5~11):(1.5~2):(1.1 ~1.6).

[0032] Step 2: Synthesize fluorine-containing polyarylether nitrile by aromatic nucleophilic substitution reaction under normal pressure.

[0033] 201. First, add the monomers of the above raw materials and anhydrous potassium carbonate into a 100mL three-neck flask, equipped with a mechanical stirrer, add sulfolane (TMS) and toluene, ...

Embodiment 1

[0050] Prepare materials with the molar ratio of bisphenol AF:2,6 dichlorobenzonitrile:sulfolane:toluene:potassium carbonate=1:1:11:2:1.1.

[0051] Put various raw materials in a three-necked flask equipped with a water separator, a condenser, and a stirrer, slowly introduce nitrogen gas, keep azeotropic at 165°C for 2 hours, and release the water generated by the reaction through the water separator. Continue to raise the temperature to about 175°C and react for 0.3h, continue to dehydrate, then release all the toluene, raise the system temperature to 220°C, react for 4 hours, and stop the reaction when rod climbing occurs. The reaction solution in the three-necked bottle was poured into the prepared dilute hydrochloric acid (PH=5) while hot to obtain off-white fibrous product. After pulverizing and drying, wash with boiling water for 20 minutes, dissolve with acetone (10 mL of solvent per gram of product is added to dissolve it), and precipitate in deionized water again, and...

Embodiment 2

[0055] Prepare materials with the molar ratio of bisphenol AF:2,6 dichlorobenzonitrile:sulfolane:toluene:potassium carbonate=1:1:8:1.6:1.3.

[0056] Put various raw materials in a three-necked flask equipped with a water separator, a condenser, and a stirrer, slowly introduce helium gas, keep azeotroping at 160°C for 3 hours, and release the water generated by the reaction through the water separator. Continue to raise the temperature to about 185°C and react for 0.5h, continue to dehydrate, then release all the toluene, raise the temperature of the system to 230°C, react for 4.5 hours, and stop the reaction when rod climbing occurs. The reaction solution in the three-necked flask was poured into methanol while hot to obtain off-white fibrous product. After crushing and drying, wash with boiling water for 30 minutes, dissolve with tetrahydrofuran (add 12 mL of solvent per gram of product to dissolve it), and precipitate in deionized water again, and after washing and suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com