High-build nanometer unsaturated polyester wood coating and preparation method thereof

A kind of wood coating, unsaturated technology, applied in the direction of polyester coating, anti-corrosion coating, fire-proof coating, etc., can solve the problems of poor flame retardant effect, uneven gloss, poor mechanical properties, etc., achieve improved corrosion resistance and simple preparation process , the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

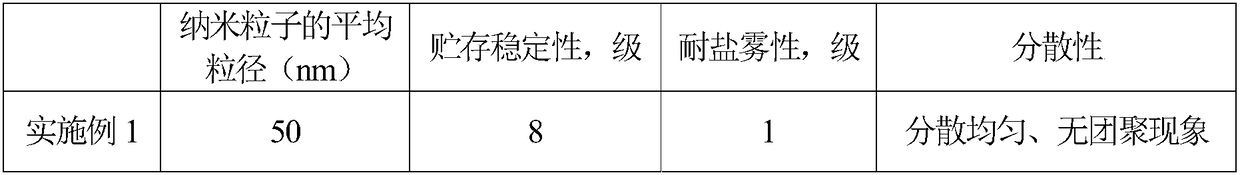

Embodiment 1

[0030] In the present embodiment, the composition and content of the thick-build nano-unsaturated polyester wood coating are as follows in parts by weight: 100 parts of unsaturated polyester resin, 18 parts of nano-composite mother liquor, and 0.8 parts of composite corrosion inhibitor , 7 parts of organic corrosion inhibitor, 2 parts of flame retardant filler, 4 parts of initiator, 3 parts of accelerator, 8 parts of organic solvent; wherein, the organic corrosion inhibitor is zinc p-nitrocinnamate, the initiator is methyl ethyl ketone peroxide, The accelerator is cobalt epoxy acid, the organic solvent is acetone; the flame retardant filler is mixed with quartz powder and antimony trioxide in a weight ratio of 1:1, and the particle size is 50-100nm.

[0031] In the nano-composite mother liquor, the weight ratio of nano-titanium dioxide, nano-silica, nano-zinc oxide and organic solvent is 45:35:25:35, the coupling agent accounts for 4% of the total weight of the above-mentioned ...

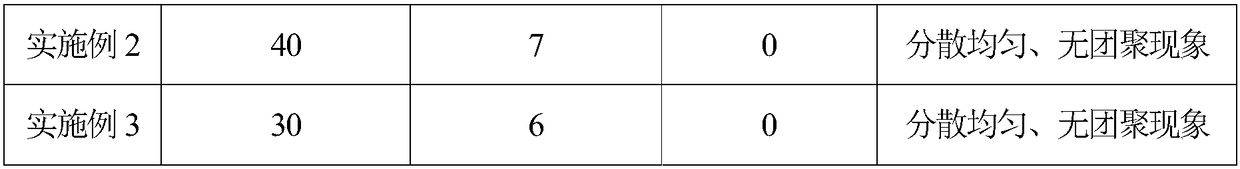

Embodiment 2

[0040] In the present embodiment, the composition and content of the thick-build nano-unsaturated polyester wood coating are as follows in parts by weight: 100 parts of unsaturated polyester resin, 15 parts of nano-composite mother liquor, and 1.0 parts of composite corrosion inhibitor , 6 parts of organic corrosion inhibitor, 3 parts of flame retardant filler, 3 parts of initiator, 4 parts of accelerator, and 5 parts of organic solvent; among them, the organic corrosion inhibitor is calcium p-nitrocinnamate, and the initiator is methyl peroxide Butanone, the accelerator is N,N-dimethylaniline, the organic solvent is acetone; the flame-retardant filler is mixed with quartz powder and asbestos fiber in a weight ratio of 2:1, and the particle size is 50-100nm.

[0041] In the nano-composite mother liquor, the weight ratio of nano-titanium dioxide, nano-silica, nano-zinc oxide and organic solvent is 40:40:20:50, the coupling agent accounts for 3% of the total weight of the above-m...

Embodiment 3

[0050] In the present embodiment, the composition and content of the thick-build nano-unsaturated polyester wood coating are as follows in parts by weight: 100 parts of unsaturated polyester resin, 20 parts of nano-composite mother liquor, and 0.5 part of composite corrosion inhibitor , 8 parts of organic corrosion inhibitor, 1 part of flame retardant filler, 5 parts of initiator, 2 parts of accelerator, and 10 parts of organic solvent; among them, the organic corrosion inhibitor is zinc p-nitrocinnamate, and the initiator is tert-butyl peroxide Hydrogen oxide, the accelerator is N,N-diethylaniline, the organic solvent is acetone; the flame retardant filler is mixed with asbestos fiber and antimony trioxide in a weight ratio of 1:2, and the particle size is 50-100nm.

[0051] In the nano-composite mother liquor, the weight ratio of nano-titanium dioxide, nano-silica, nano-zinc oxide and organic solvent is 50:30:30:20, the coupling agent accounts for 5% of the total weight of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com