Method for preparing high-purity nano hafnium boride from molten salt through electrolysis

A technology of molten salt electrolysis and nano-boron, applied in the field of electrolytic metallurgy, can solve the problems of difficult control of C element content, large-scale production difficulty, and expensive metal hafnium, and achieve simple equipment, easy industrial continuous production, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

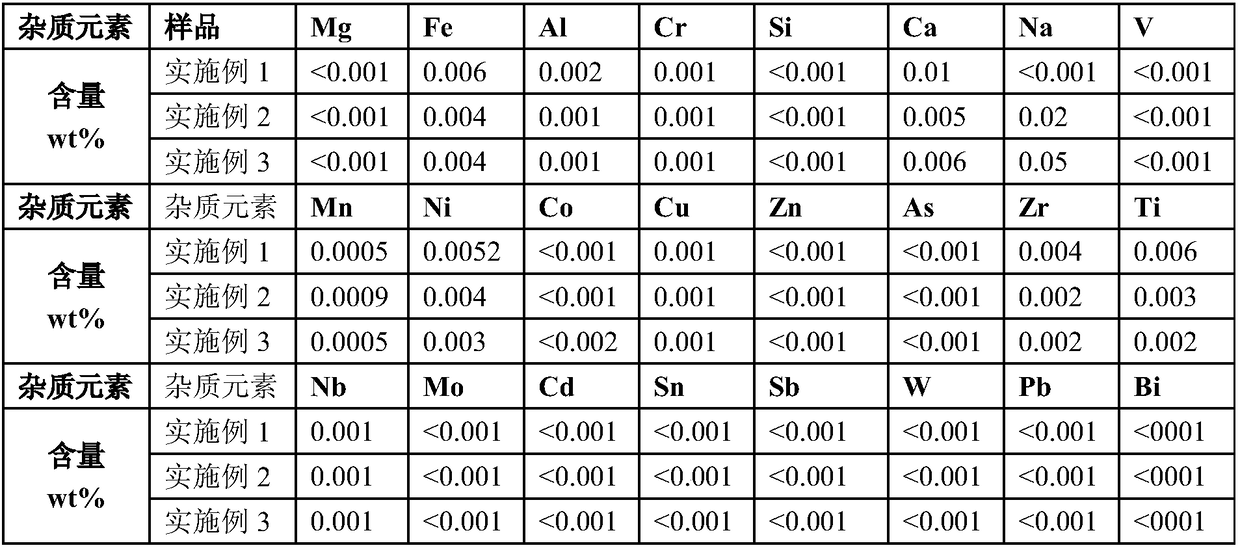

[0023] HfO with a purity of 99.9% 2 The powder and boron powder are uniformly mixed at a molar ratio of 1:2, and formed by mechanical pressure to form a rectangular block with a length of 70mm, a width of 50mm, and a thickness of 10mm.

[0024] The rectangular block is combined with a conductive cathode current collector as the cathode, the graphite rod is used as the anode, and the CaCl 2 As an electrolyte, in an argon environment, 950°C, and a cell voltage of 3.0V, use a regulated power supply to control the voltage and perform constant voltage electrolysis;

[0025] After electrolysis, the electrolysis product is washed with 1% by volume dilute hydrochloric acid and pure water in turn, dried in vacuum and sieved to obtain high-purity HfB 2 powder.

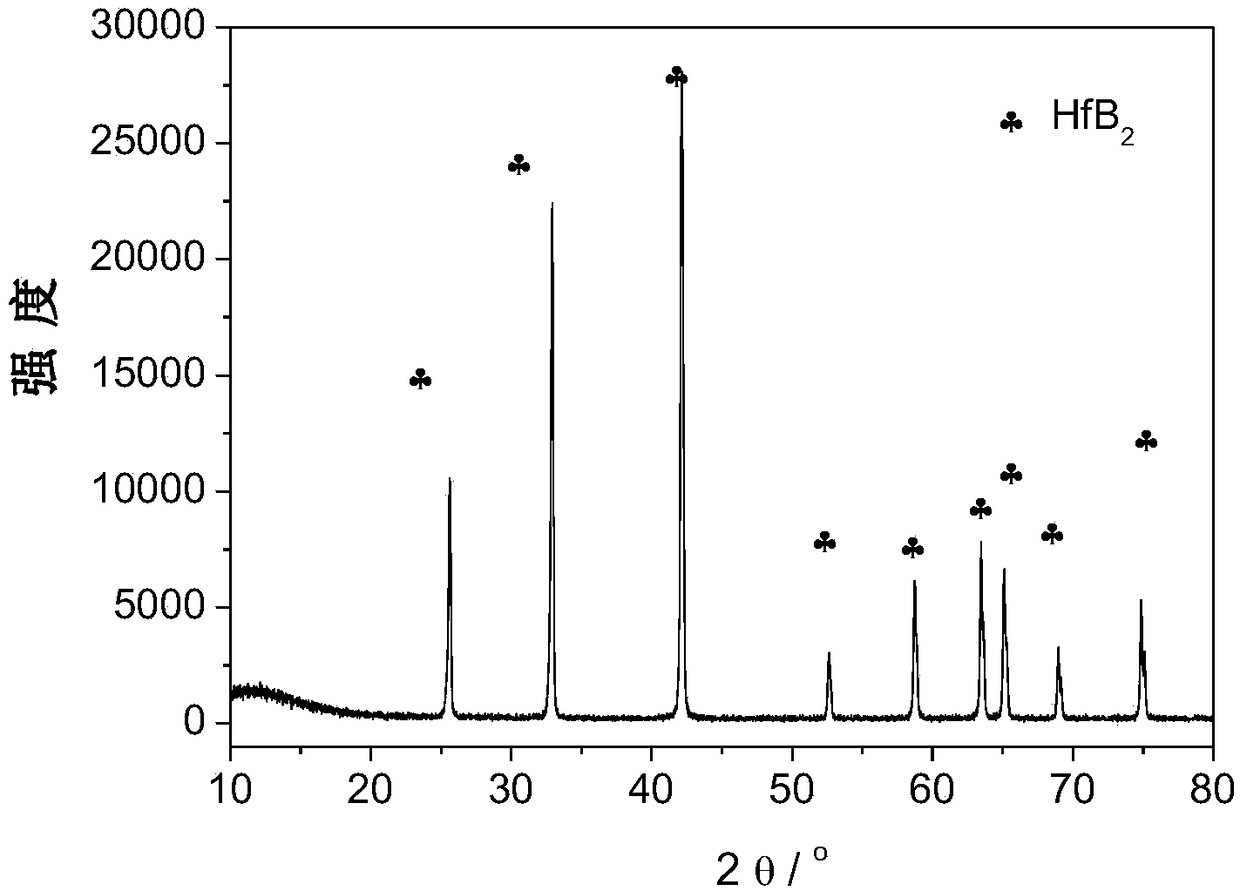

[0026] The resulting product is subjected to purity analysis and XRD characterization, see Table 1 and attached figure 1 , the product purity reaches 99.96wt%.

Embodiment 2

[0028] HfO with a purity of 99.9% 2 The powder and boron powder are uniformly mixed at a metering ratio of 1:2, and formed by mechanical pressure to form a rectangular block with a length of 70mm, a width of 50mm, and a thickness of 10mm.

[0029] Combining a rectangular block with a conductive cathode current collector as the cathode, using a graphite rod as the anode, and using NaCl as the electrolyte, in an argon environment, 700°C, and a cell voltage of 2.9V, use a regulated power supply to control the voltage to perform constant voltage electrolysis ;

[0030] After electrolysis, the electrolysis product is washed with 1% by volume dilute hydrochloric acid and pure water in turn, dried in vacuum and sieved to obtain high-purity HfB 2 powder.

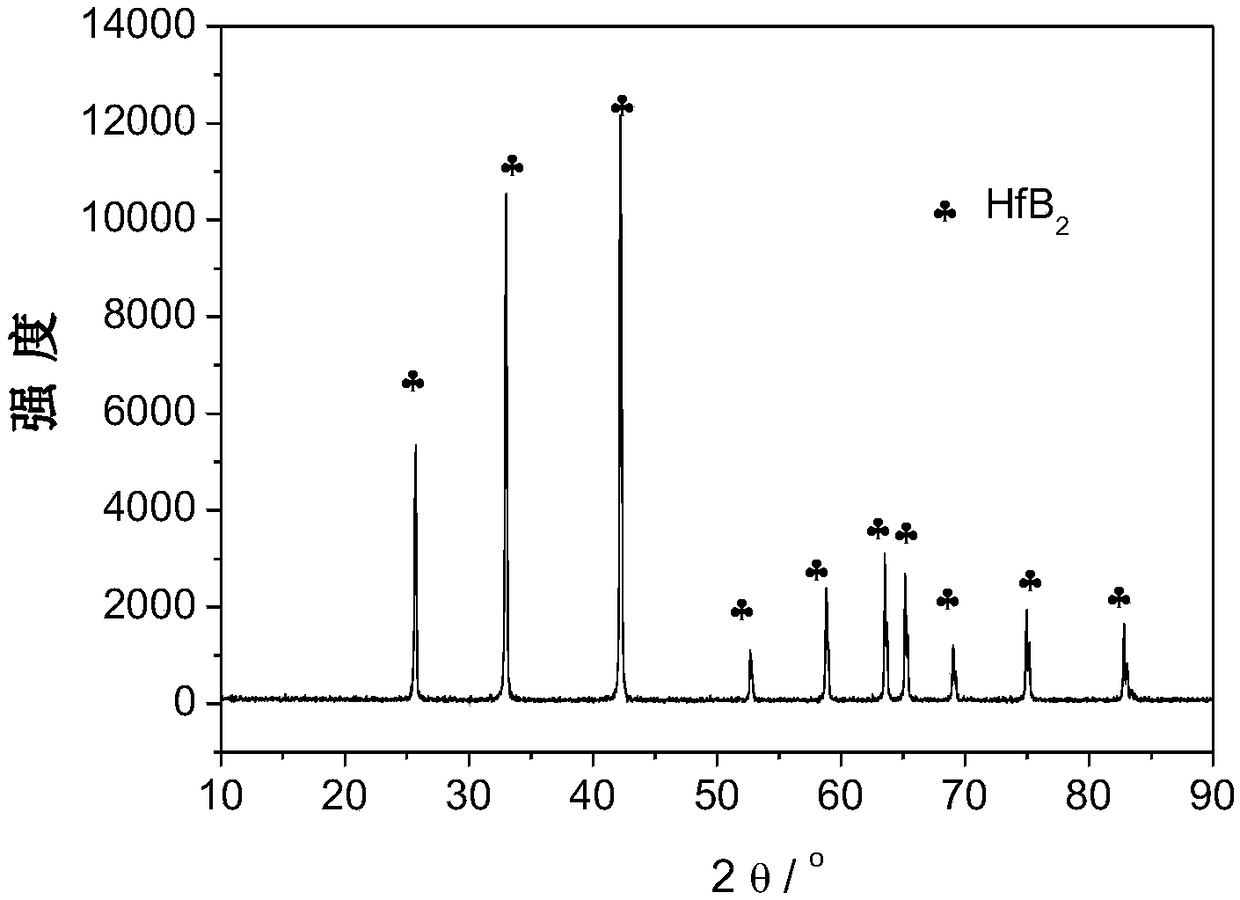

[0031] The resulting product is subjected to purity analysis and XRD characterization, see Table 1 and attached figure 2 , the product purity reaches 99.95wt%.

Embodiment 3

[0033] HfO with a purity of 99.9% 2 The powder and boron powder are uniformly mixed at a metering ratio of 1:2, and formed by mechanical pressure to form a rectangular block with a length of 70mm, a width of 50mm, and a thickness of 10mm.

[0034] The rectangular block is combined with a conductive cathode current collector as the cathode, the graphite rod is used as the anode, and the NaCl:CaCl 2 The mixed molten salt electrolyte with a molar ratio of 1:1 is used as the electrolyte. In an argon environment, 600°C, and a cell voltage of 2.9V, the voltage is controlled by a regulated power supply to perform constant voltage electrolysis;

[0035] After electrolysis, the electrolysis product is washed with 1% by volume dilute hydrochloric acid and pure water in turn, dried in vacuum and sieved to obtain high-purity HfB 2 powder.

[0036] The resulting product was analyzed for purity, see Table 1 for details, and the product purity reached 99.92wt%.

[0037] Gained product imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com