Electrochemical oxidation device for removing chloride ions in water

An oxidation device and electrochemical technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. problems, to achieve good environmental and economic benefits, easy processing, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

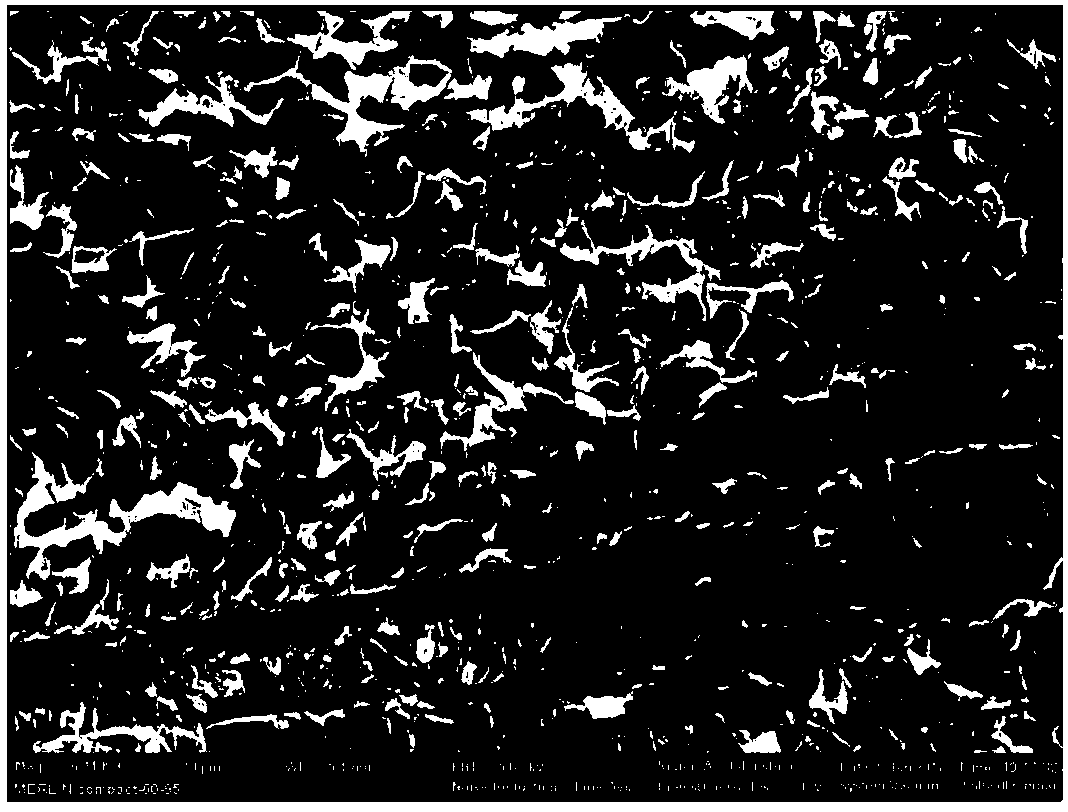

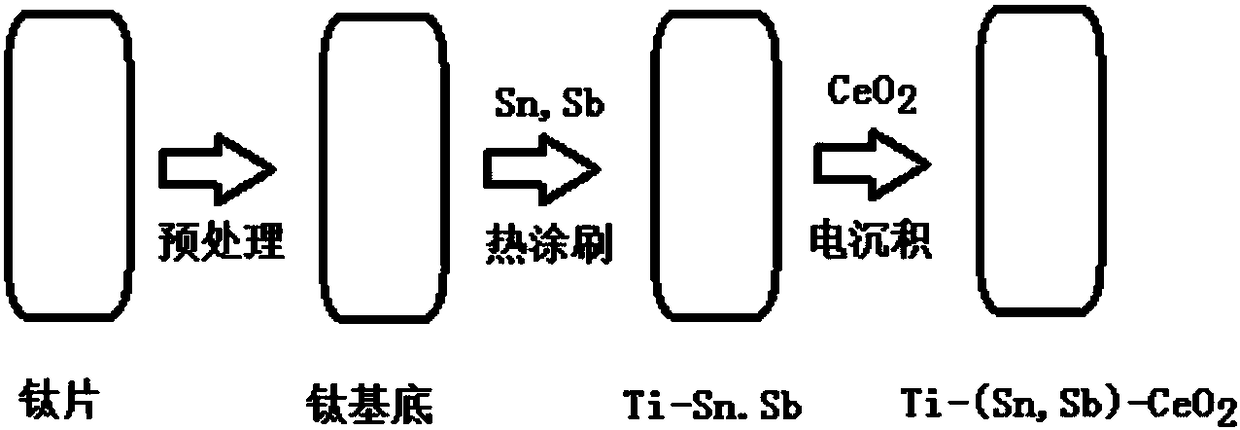

[0034] The preparation steps of the oxide anode are as follows: (1) pretreatment of the titanium sheet: the titanium sheet is polished with sandpaper to show a bright color, soaked in 12% hydrochloric acid for 40 minutes, and then rinsed with deionized water;

[0035] (2) Get antimony trichloride and tin tetrachloride, join in ethanol solution, make it dissolve, control the mol ratio of tin and antimony to be 12:1; Obtain the ethanolic solution of antimony trichloride and tin tetrachloride; Apply an ethanol solution of antimony trichloride and tin tetrachloride to the surface of the treated titanium sheet; after coating evenly on both sides, dry it at 80-90 degrees Celsius, take it out and calcinate it at 550-600 degrees Celsius for 10 minutes ; The above steps are repeated 5-8 times, and the last calcination time is 2 hours to obtain an electrode with an intermediate layer for subsequent use;

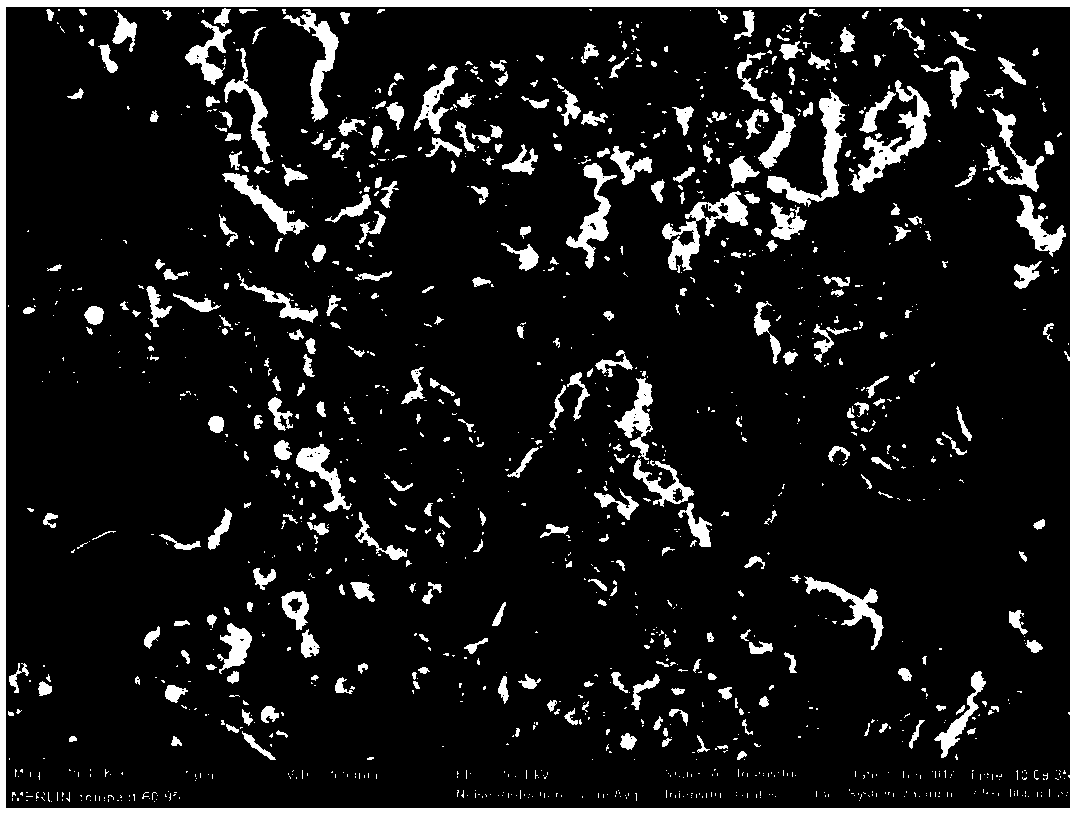

[0036] (3) get light yellow cerium oxide and copper nitrate to add water and nitri...

Embodiment 2

[0039] The specific structure is the same as in the examples, the difference being the preparation conditions of the oxide anode;

[0040] The preparation steps of the oxide anode are as follows: (1) pretreatment of the titanium sheet: the titanium sheet is polished with sandpaper to present a bright color, soaked in 18% hydrochloric acid for 30 minutes, and then rinsed with deionized water;

[0041] (2) Get antimony trichloride and tin tetrachloride, join in the ethanol solution, make it dissolve, apply the ethanol solution that is uniform antimony trichloride and tin tetrachloride to the surface of treated titanium sheet, control tin and tin tetrachloride The molar ratio of antimony is 6:1; when both sides are evenly coated, dry at 80-90 degrees Celsius, take it out and calcine at 550-600 degrees Celsius for 10 minutes; repeat the above steps 5-8 times, the last calcination time For 2 hours, the electrode with the intermediate layer was obtained and set aside;

[0042] (3) ge...

Embodiment example 1

[0053] Implementation case 1: Use the above preparation method to prepare the required anode, and treat the sewage drainage of Hubei Jinao Technology Co., Ltd. The quality of sewage drainage is: chloride ion 625.7mg / L, hardness 5.42mmol / L, ammonia nitrogen about 1.877mg L -1 , pH = 6.2-6.5, through the design of the treatment tank volume 3L; 138cm 2 (four pieces), cathode area: 138cm 2 (four pieces).

[0054] The device is first filled with 3L of wastewater (without pH adjustment), powered on under different conditions, and treated statically for 3 hours to ensure that the chlorine ions in the 3L wastewater in the treatment pool are reduced by 80%, and then turn on the constant flow pump to control the flow and retention of water in and out. Time, treated according to different conditions, sampling once an hour, monitoring the chloride ion concentration of the water sample in the drainage pool, running continuously for each test, the chlorine ion in the effluent is stable at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com