Method for preparing high-performance inorganic/organic composite multilayer dielectric film by surface coating process and application thereof

A technology of dielectric film and coating process, applied in the field of new energy materials for energy storage of high-performance capacitors, can solve problems affecting the application range of capacitors, etc., and achieve excellent charging and discharging efficiency, low production cost, heat dissipation and heat resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

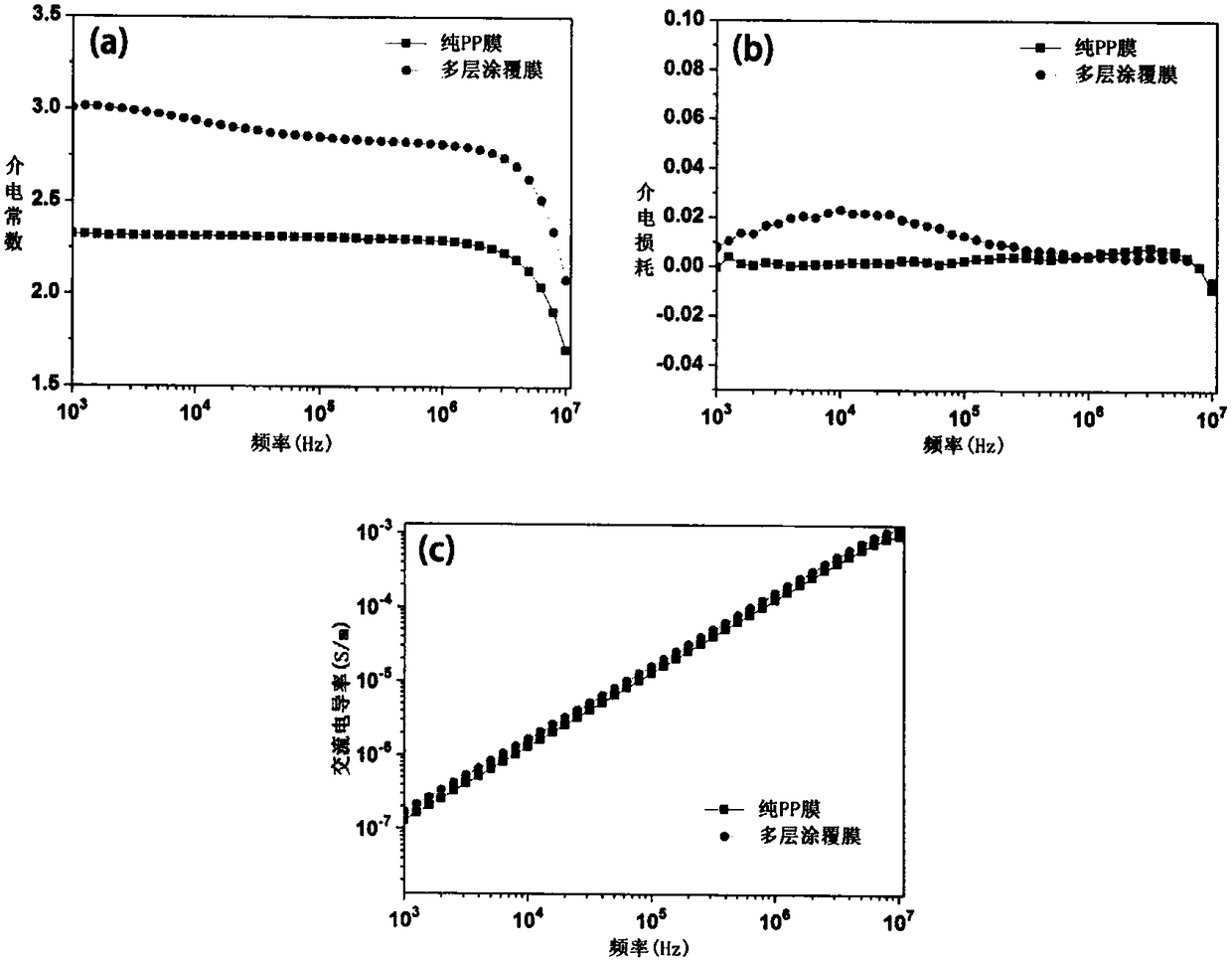

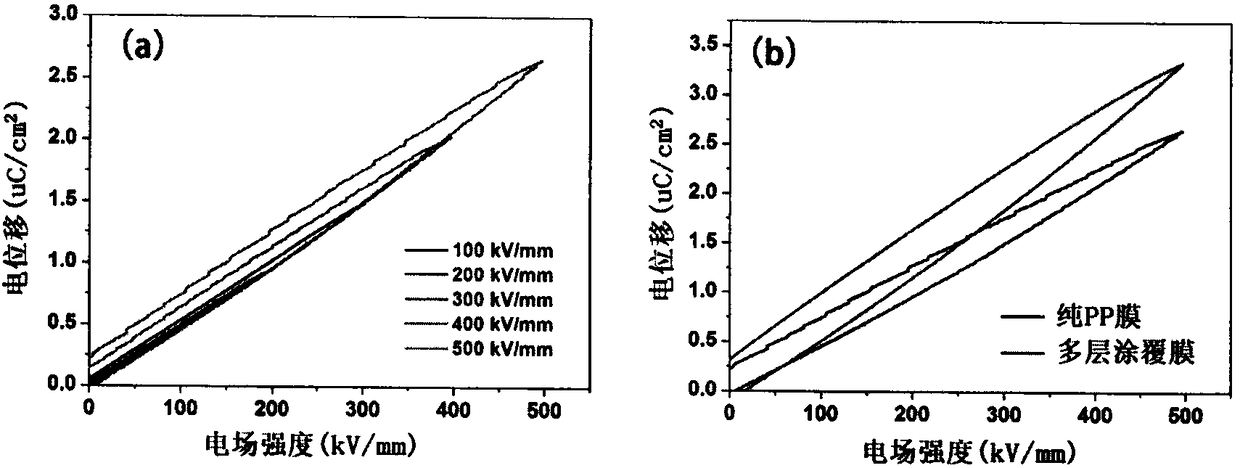

[0014] Embodiment: A method for preparing a high-performance inorganic / organic composite multilayer dielectric film by a surface coating process and a test experiment.

[0015] (1) Preparation of composite coating layer

[0016] Ultrasonically disperse 0.8 kg of nano-particle barium titanate with a mass fraction of 8% in 6.7 kg of water, then weigh 2.5 kg of a water-based binder with a mass fraction of 4%, and 0.001 kg of a defoamer, using a sand mill Sand mill for 2 hours to disperse into a suspension slurry.

[0017] (2) Coating of composite coating layer

[0018] The suspension slurry in the above (1) is coated on one side of a pure polypropylene (PP) film with a thickness of 6 to 13 microns using a 120-mesh roller coater, and the length and temperature of the oven are 15 meters and 60 meters respectively. ℃, so as to carry out sufficient drying to obtain the multi-layer high dielectric film material provided by the present invention. Among them, the thickness of the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com