High-intensity electromagnetic shielding material for new energy electric vehicle and preparation method thereof

An electromagnetic shielding material, technology for electric vehicles, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve problems such as being unfavorable to industrialization, weak mechanical properties, difficult processing, etc., to improve electromagnetic shielding efficiency, mechanical properties, and molding processes simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

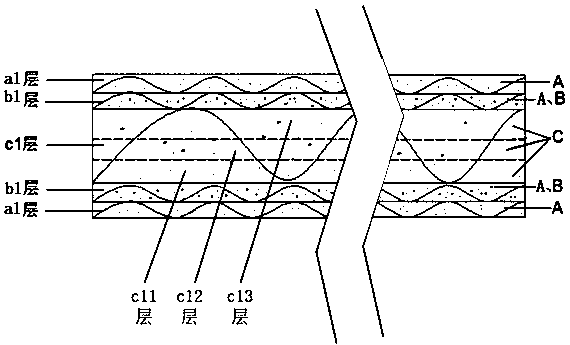

Image

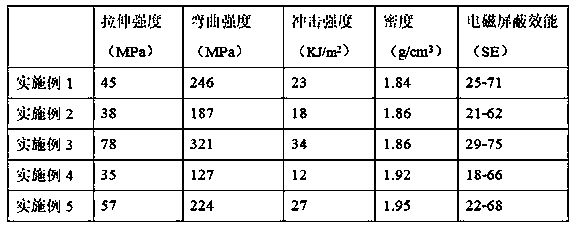

Examples

Embodiment 1

[0047] Prepare the modified polymer solution of the magnetic medium wave-absorbing filler A: After the nickel-zinc ferrite surface is subjected to surface coupling treatment with γ-aminopropyltriethoxysilane, it is added to the epoxy resin solution and stirred evenly.

[0048] Prepare the composite modified polymer solution of magnetic dielectric wave-absorbing filler A and conductive wave-absorbing filler B: surface coupling treatment of nickel-zinc ferrite and hydroxyl iron powder through γ-aminopropyltriethoxysilane respectively, then add Stir well into the epoxy resin solution.

[0049] Preparation of conductive filler C modified polymer solution: superconducting carbon black is subjected to surface coupling treatment by γ-glycidyl etheroxypropyl trimethoxysilane, then added to epoxy resin solution and stirred evenly.

[0050] Preparation of high-strength electromagnetic shielding materials for new energy electric vehicles:

[0051] The prepared magnetic medium wave-absor...

Embodiment 2

[0061] The method is as in Example 1, and the modified polymer solution of magnetic medium wave-absorbing filler A is prepared, and manganese-zinc ferrite is used to replace nickel-zinc ferrite, and γ-glycidyl etheroxypropyl trimethoxysilane is used to replace γ-aminopropyl Triethoxysilane, an unsaturated polyester resin alternative to epoxy resins.

[0062] Prepare the composite modified polymer solution of magnetic dielectric wave-absorbing filler A and conductive wave-absorbing filler B, replace nickel-zinc ferrite with manganese-zinc ferrite, and mix hydroxy-iron powder and hydroxy-nickel powder in a ratio of 1:1 to replace hydroxy-iron powder. γ-glycidyl etheroxypropyl trimethoxysilane replaces γ-aminopropyl triethoxysilane, and unsaturated polyester resin replaces epoxy resin.

[0063] Prepare conductive filler C modified polymer solution, replace superconducting carbon black with graphite, replace γ-glycidyl etheroxypropyl trimethoxysilane with γ-aminopropyl triethoxysi...

Embodiment 3

[0071] The method is as in Example 1, prepare the modified polymer solution of magnetic medium wave-absorbing filler A, replace the nickel-zinc ferrite with sendust and nickel-zinc ferrite according to 1:1, γ-glycidyl ether oxypropyl trimethyl Oxysilane replaces γ-aminopropyltriethoxysilane, epoxy resin.

[0072] Prepare magnetic dielectric wave-absorbing filler A and conductive wave-absorbing filler B composite modified polymer solution, use sendust and nickel-zinc ferrite to replace nickel-zinc ferrite according to 1:1, and hydroxynickel powder to replace hydroxyiron powder. γ-glycidyl etheroxypropyl trimethoxysilane replaces γ-aminopropyl triethoxysilane, and epoxy resin does not.

[0073] Prepare conductive filler C modified polymer solution, replace superconducting carbon black with carbon nanotubes and graphene according to 1:1, γ-glycidyl etheroxypropyl trimethoxysilane, and epoxy resin does not replace.

[0074] A1 layer preparation, method as embodiment 1, glass fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com