Magnetic alloy hollow microsphere and preparation method thereof

A magnetic alloy and microsphere technology, applied in the nanometer field, can solve the problems of high temperature energy consumption, complicated and multi-step, harsh conditions, etc., and achieve the effect of no template, cheap raw materials, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 1.2g (12g / L) surfactant [polyvinylpyrrolidone (PVP)] in a mixed solution of 98mL pure ethylene glycol and 4.5mL deionized water and stir evenly, then add 0.6424g (0.027M) CoCl 2 ·6H 2 O and 0.4279g (0.018M) NiCl 2 ·6H 2 O electric power was stirred for 2 h, and then 2.5 mL of anhydrous hydrazine hydrate was added dropwise to the solution and stirred for 1 h. Then the mixture was heated to 197°C to boil, condensed and refluxed for four hours. After cooling, it was washed with absolute ethanol for multiple times of magnetic separation and separation until the solution was clear, and finally dried to obtain the required magnetic alloy hollow microspheres.

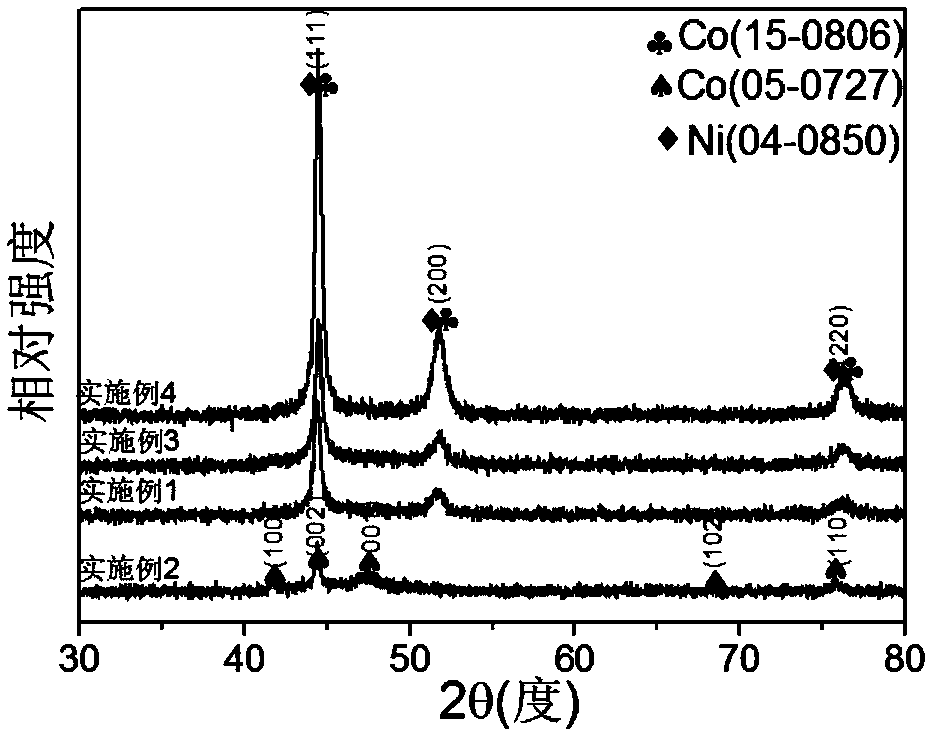

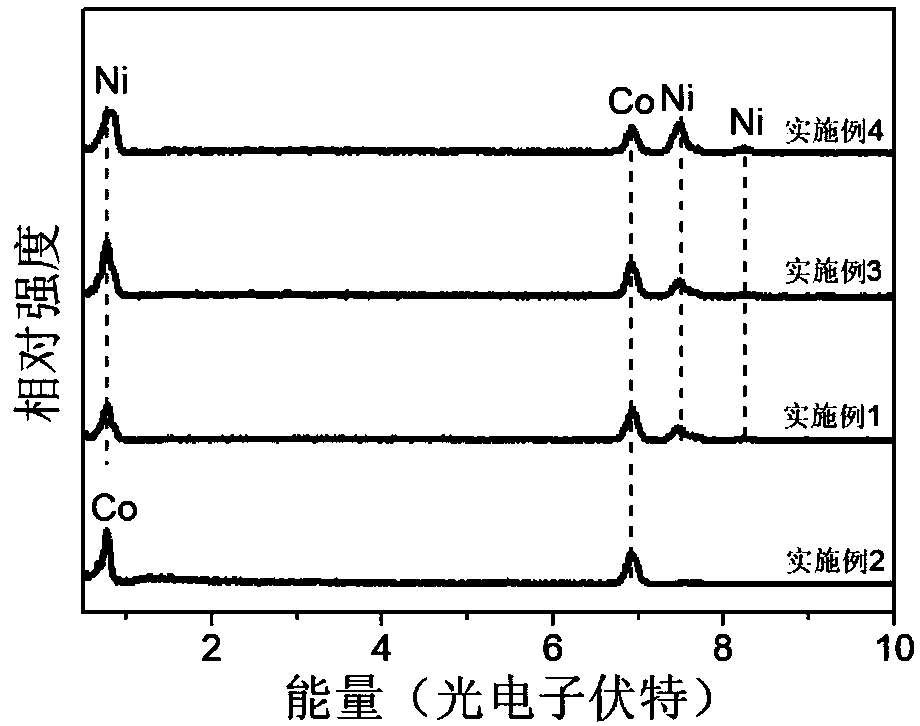

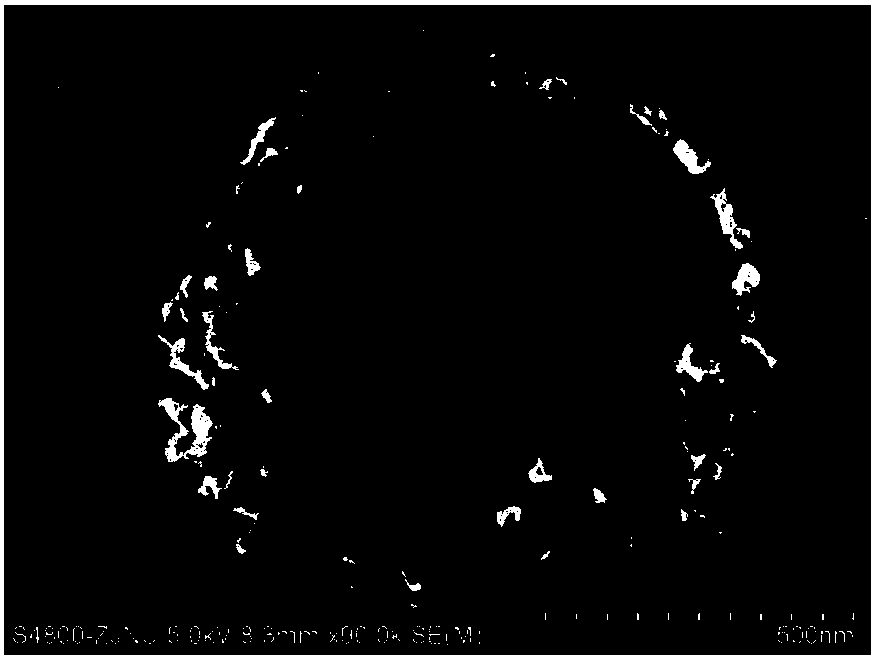

[0034] The phase, elemental composition and morphology of the obtained product observed under the scanning electron microscope are as follows: Figure 1~3 As shown, the particle diameter is 0.72~1.68μm, and the wall thickness is 28~73nm; figure 2 As shown, the Co / Ni atomic ratio is 1.96; the static magneti...

Embodiment 2

[0036] Same step as Example 1, but only add 1.0706g (0.045M) CoCl in the solution 2 ·6H 2 O, the morphology of the resulting product observed under the scanning electron microscope is as follows Figure 8As shown, the particle diameter is 0.84-1.85 μm, and the wall thickness is 4-17 nm. Static magnetic properties such as Figure 5 , the saturation magnetization is 152.89emu·g -1 ; Its two-dimensional reflectivity is as follows Figure 9 As shown, paraffin is used as the base, when the mass fraction is 50%, the reflectance is -18.08dB at 2GHz, and the sample thickness is 7.9mm.

Embodiment 3

[0038] Same as Example 1, but add 0.5353g (0.0225M) CoCl to the solution simultaneously 2 ·6H 2 O and 0.5348g (0.0225M) NiCl 2 ·6H 2 O. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 10 As shown, the particle diameter is 0.76-1.82 μm, and the wall thickness is 47-78 nm. Energy spectrum analysis such as figure 2 As shown, the Co / Ni atomic ratio is 1.69. Static magnetic properties such as Figure 5 , the saturation magnetization is 105.93emu g -1 ; its electromagnetic parameters such as Figure 5-6 As shown, in the frequency range of 2-18GHz, the real part and imaginary part of the permittivity increase by 0.75-1.39 and 0.21-0.79 times respectively compared with the hollow Co sphere, and the real part and imaginary part of the permeability increase by 0.98-1.02 compared with the and 0.11 to 0.96 times. Its two-dimensional reflectivity is as Figure 11 As shown, paraffin is used as the base, when the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com