Preparation method of organic silicon polymer

A polymer and organosilicon technology, applied in the field of organosilicon polymer preparation, can solve the problems of difficult ultra-thinning, low separation coefficient, low cohesive energy density, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

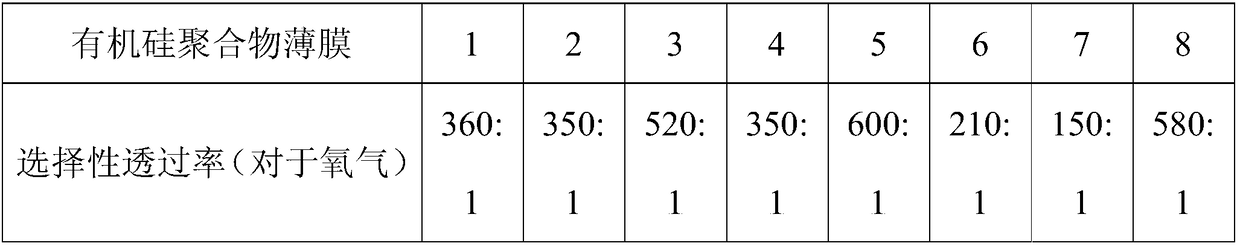

Examples

Embodiment 1

[0047] Silicone Polymer 1 was prepared by the following steps:

[0048] Step (1), add 1 mol of water to 1 mol of methyl tributylketoxime silane, hydrolyze at 35 ° C for 4 hours, vacuumize the reaction system to a vacuum of 0.05Mpa, remove the butanone oxime produced by hydrolysis, and then add to the reaction Add 4mol of higher alcohol 1-octanol into the system, let it stand for 2 hours, then carry out the condensation reaction, the reaction temperature is 60°C, the reaction time is 15 hours, and the reaction system is vacuumed to a vacuum degree of 0.02Mpa for vacuum treatment to remove the remaining small molecules, resulting in condensation products;

[0049] Step (2), add 10mol octamethylcyclotetrasiloxane and catalyst tetramethylammonium hydroxide in the condensation product that obtains in step (1), make the concentration of catalyst in the reaction system be 100ppm, keep vacuum constant , stirred at 80°C for 30 hours to carry out the chain extension reaction, and the c...

Embodiment 2

[0052] Silicone polymer 2 was prepared by the following steps:

[0053] The only difference from Example 1 is that in step (1), methyl tributylketoxime silane is replaced by vinyl tributylketoxime silane, the amount of water added is 0.8mol, and the hydrolysis condition is a hydrolysis temperature of 45°C , The hydrolysis time is 2h, the higher alcohol is 1-hydroxyhexadecane, the condensation reaction temperature is 80°C, and the condensation reaction time is 6h.

[0054] Example 2 obtains silicone polymer 2.

Embodiment 3

[0056] Silicone polymer 3 was prepared by the following steps:

[0057] The only difference from Example 1 is that the addition of octamethylcyclotetrasiloxane in step (2) is 15 mol, the temperature of constant temperature stirring is 120 ° C, the time is 8 h, and the reaction reaches a viscosity of 48000 mPa·s chain extension products.

[0058] Example 3 yielded silicone polymer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com