Feed additive for lactating sow feed, lactating sow feed and preparation methods thereof

A technology for sucking sows and additives, applied in animal feed, animal feed, applications, etc., can solve problems such as unfavorable growth and reproduction of piglets, survival rate of weaned piglets, low weight of weaned piglets, and impact on farm economic benefits, etc., to shorten the estrus time The effect of spacing, enhancing the sow's physique, and avoiding constipation in sows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

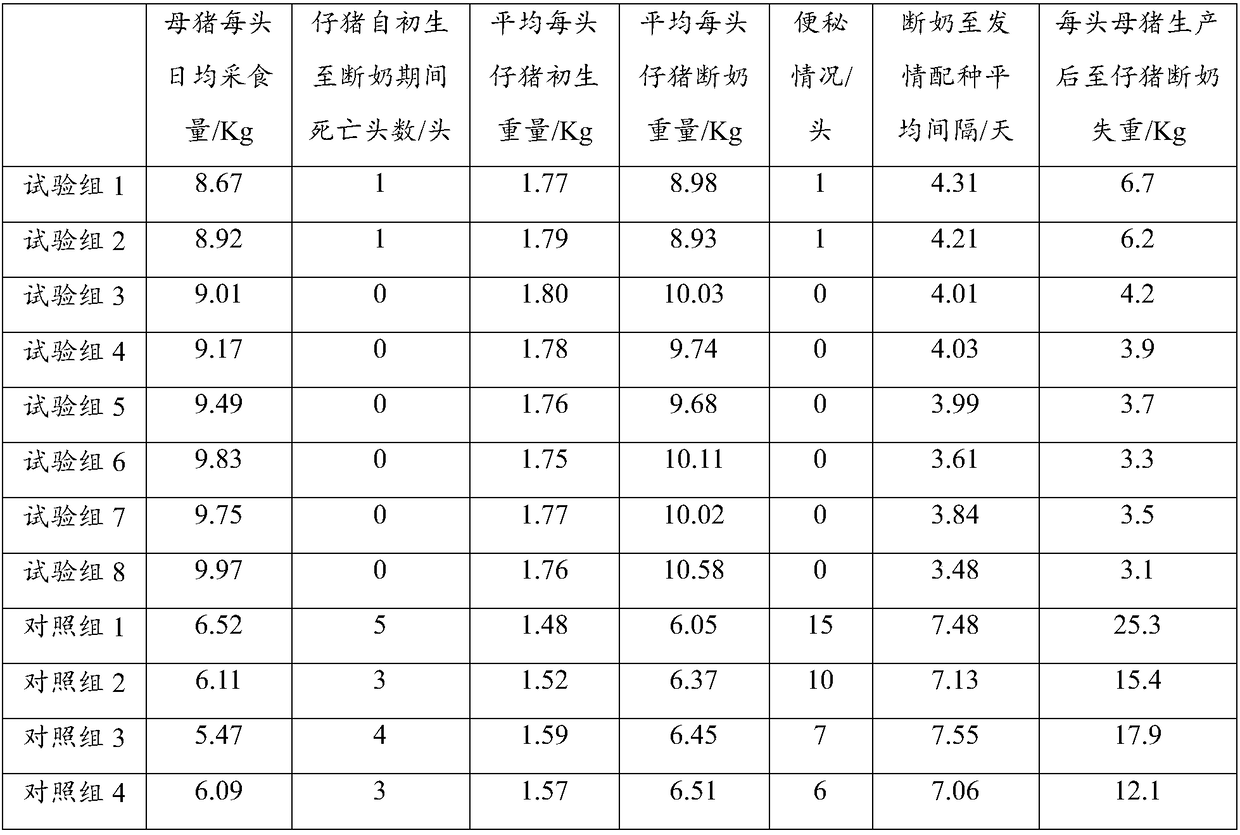

Examples

Embodiment 1

[0042] The present embodiment provides a feed for lactating sows, comprising:

[0043] 29 parts of puffed soybeans, 14 parts of brown sugar, 13 parts of fish meal, 10 parts of calcium hydrogen phosphate, 1 part of sodium chloride, 0.3 parts of lysine, 1.5 parts of compound enzyme, 1.5 parts of compound microbial bacteria and 8 parts of compound plant extract;

[0044] The compound enzyme includes xylanase, cellulase and mannanase with a mass ratio of 35:2:1;

[0045] The compound plant extracts include purslane extract, baicalin, berberine, honeysuckle extract and cork extract in a mass ratio of 1:5:1:5:1;

[0046] Composite microorganisms include: Bacillus subtilis, Lactobacillus plantarum, Bacillus licheniformis and Bacillus coagulans, the total viable count of composite microorganisms is 1.3×10 8 cfu / g.

[0047] The preparation method of above-mentioned feed for lactating sows, comprising

[0048] Mix the compound enzyme, compound microbial bacteria and compound plant ex...

Embodiment 2

[0050] The present embodiment provides a feed for lactating sows, comprising:

[0051] 25 parts of puffed soybean, 17 parts of brown sugar, 4 parts of glucose, 6 parts of soybean protein concentrate, 7 parts of stone powder, 2 parts of sodium chloride, 1 part of choline chloride, 0.1 part of lysine, 0.03 part of methionine, 0.5 part of compound enzyme , 1 part of compound microbial bacteria, 3 parts of compound plant extract and 4 parts of premixed feed;

[0052] Compound enzymes include xylanase, cellulase, mannanase, amylase, acid protease, neutral protease, glucose oxidase with a mass ratio of 84:8:14:4:19:31:5:0.1 and galactosidase;

[0053] The compound plant extracts include purslane extract, baicalin, berberine, honeysuckle extract and cork extract in a mass ratio of 5:1:5:1:5;

[0054] Composite microorganisms include: Bacillus subtilis, Lactobacillus plantarum and Bacillus coagulans, the total number of viable bacteria of composite microorganisms > 1.3×10 8 cfu / g; ...

Embodiment 3

[0061] The present embodiment provides a feed for lactating sows, comprising:

[0062] 15 parts of puffed soybeans, 20 parts of brown sugar, 2 parts of glucose, 10 parts of concentrated soybean protein, 5 parts of fermented soybean meal, 20 parts of fish meal, 8 parts of calcium hydrogen phosphate, 10 parts of stone powder, 1 part of sodium chloride, 1.5 parts of sodium bicarbonate, 0.5 parts of choline chloride, 0.4 parts of lysine, 0.01 parts of methionine, 1.5 parts of compound enzymes, 0.5 parts of compound microorganisms, 8 parts of compound plant extracts and 4 parts of premixed feed.

[0063] The compound enzyme includes xylanase, cellulase, mannanase, amylase, acid protease, neutral protease, glucose oxidase with a mass ratio of 87:5:10:10:15:35:4:3 and galactosidase; the amylase selected in this embodiment is a low-temperature amylase, that is, the applicable temperature is lower than 60°C;

[0064] Compound plant extracts include purslane extract, baicalin, berberin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total viable bacteria | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com